Information on material change to SL-17 Yoke

- Safety Flash

- Published on 1 September 2000

- Generated on 25 February 2026

- IMCA SF 05/00

- 2 minute read

Jump to:

Below is copied an information bulletin received from Divex.

Change to Product Bulletin 2 of 2000: 3 Aug , 2000 (Revision of Bulletin 1 of 1999)

Subject: Material change to SL-17 Yoke

Products Affected: Yokes for all SuperLite 17 A/B and MK 21 Helmets.

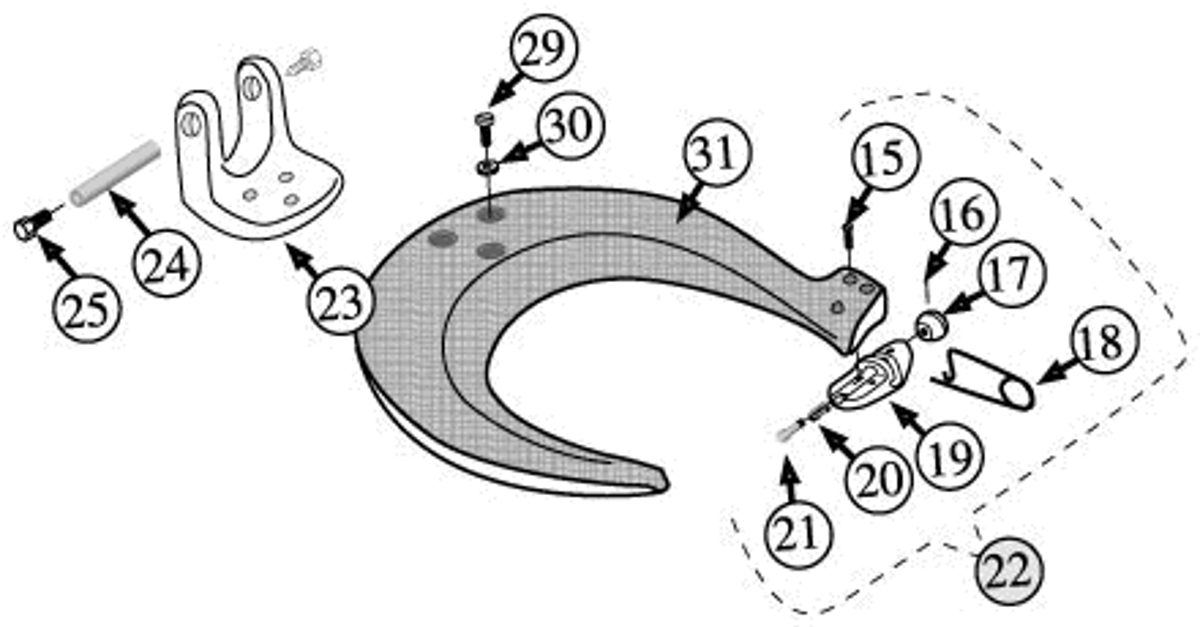

DSI is replacing the existing fiberglass yoke (31), DSI Part Number 520-060, with a new yoke, DSI Part Number 520-117 (no price change). The new yoke is made of a durable black polyurethane, molded around a stainless steel core, and is slightly heavier than the fiberglass. This yoke will become standard equipment on all SuperLite 17 A/B & MK 21 helmets produced as of June 15, 1999.

The new yoke is fully retrofittable with the fiberglass unit it replaces and is readily retrofittable to all SL-17 A/B helmets. The only difference is that the three stainless washers, (DSI Part Number 530-530 – location number 30 on the exploded view), used on the fiberglass yoke hinge installation are not used on the polyurethane yoke hinge installation.

Old Part Number: 520-060

This fiberglass yoke will remain available as a special order spare part.

New Part Number: 520-117

Note: There is no change of part number for the neckclamp / yoke assembly, 505-008 which is also now standard with the new black polyurethane yoke. No Price Change.

© 2000 Diving Systems International, Inc. All Rights Reserved. Docu #0008030011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.