Incident during winch-to-winch wire transfer operations

- Safety Flash

- Published on 1 June 2003

- Generated on 30 June 2025

- IMCA SF 05/03

- 3 minute read

Jump to:

A Member has reported a serious incident which occurred recently on an offshore vessel when a 7-ton SWL wire sling parted.

What happened?

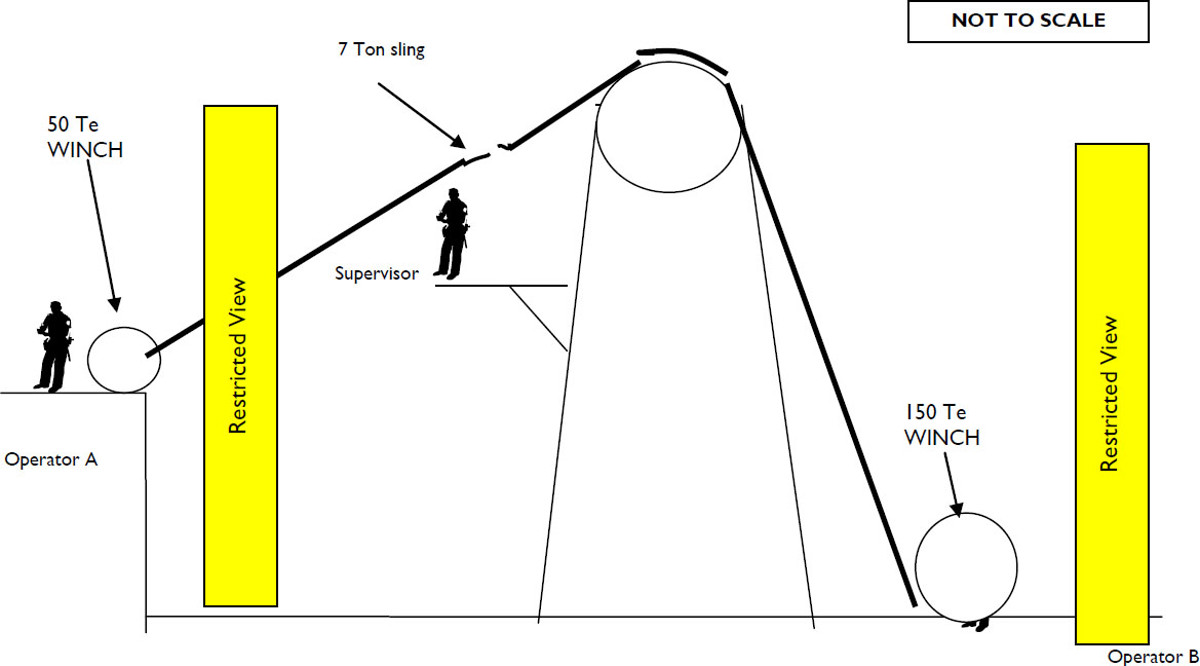

From the diagram below, it can be seen that the operation was totally reliant on the use of co-ordinated radio communications, as both winch operators were unable to maintain a line of sight with the operation.

As the wire connection arrived at the work platform, the supervisor called an ‘all stop’, which was not heard by ‘Operator A’. The 50te winch continued to pull the 150te winch wire and the resulting tension caused the trip on the 150te winch to cut out. The 150te winch was fitted with a cut-out switch to prevent overloading, which had been previously set at 32te.

The supervisor called out two more ‘all stop’ commands, that were also not heard by Operator A. The tension in the rigging continued to rise as the 50te winch continued to pull. When the tension reached 42te, the 7-ton wire sling parted and the resulting whiplash destroyed the handrails on the work platform.

From the supervisor calling the initial ‘all stop’ command to the wire parting a total of six seconds had elapsed.

The company issued the following instructions for future operations:

In any winch or crane operation where a line of sight cannot be maintained, it is fundamental to use correct radio procedure and protocol. All such operations are to be subject to a formal JHA and as a minimum a toolbox talk is to be held with all personnel involved in the operation.

- When carrying out lifts or winch operations that are out of the line of vision of the winch/crane operator (normally deemed ‘blind lifts’), ensure that winch/crane operator receives a full briefing of the intended operation. Paint a verbal picture of the manoeuvres that are about to be carried out and do not proceed until he/she gives an acknowledgement of understanding.

- Full radio communication checks are to be made prior to the start of any winch or crane operation where line of sight between the operator and banksman cannot be maintained. If any doubt exists as to the efficiency of the radio communications, the operation must not proceed until full radio contact is established.

- During ‘blind winch/crane operations’ the criticality of the operation is such that the winch/crane operator must acknowledge and repeat all instructions he has received over the radio. The operation must not proceed unless a precise acknowledgement has been received from the winch/crane operator.

- During ‘blind winch/crane operations’ a hand signalling method and more than one banksman is to be used to relay instructions to the winch/crane operator. Each banksman should stand in a position where he/she can be clearly seen by the next person in the chain. All signals should be clear and precise. Wherever possible, the banksman at the load should have a complete overview of the activity.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.