Injuries during lifting operations

- Safety Flash

- Published on 19 March 2025

- Generated on 4 March 2026

- IMCA SF 05/25

- 2 minute read

Jump to:

What happened?

A member reports two separate lifting activities involving failure of lifting equipment and resulting in minor injuries to nearby personnel.

Event 1

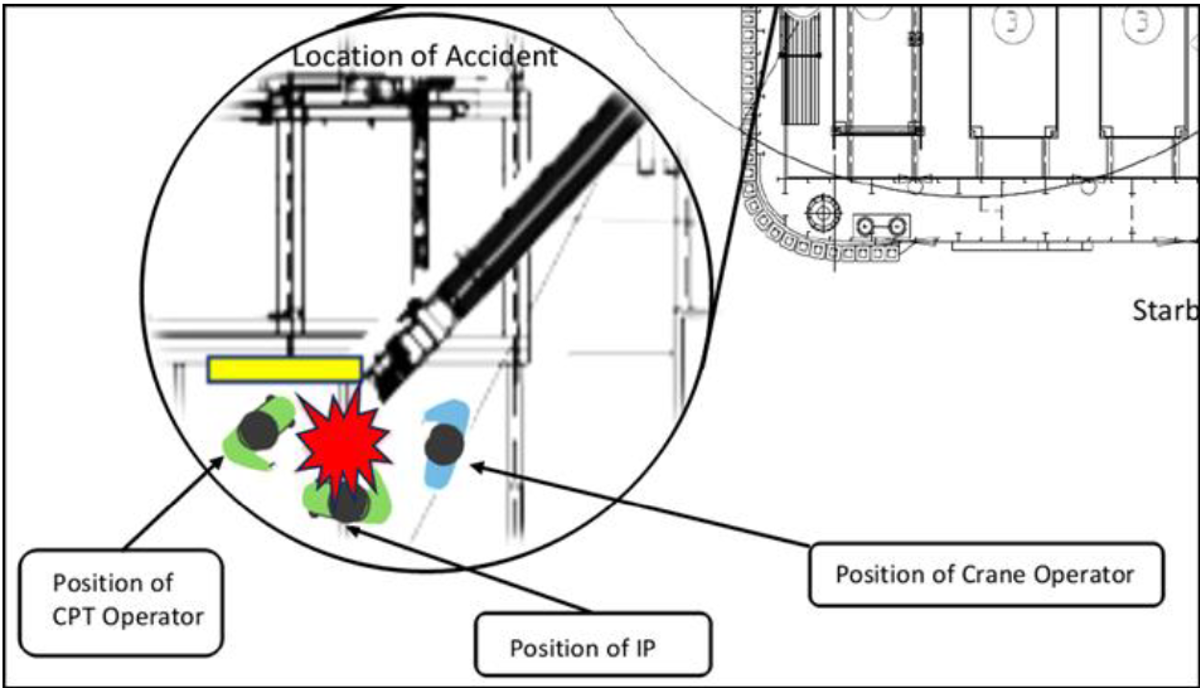

While positioning for a lift the boom of a deck-mounted 1.5t folding crane was slewed and extended causing the overhaul ball to contact the sheave (two-block), resulting in the crane wire parting. The overhaul ball, lifting hook, and lifting chains (22.5kg) fell to deck from a height of approximately 6m. A member of the work party was struck and sustained a soft tissue injury.

Event 2

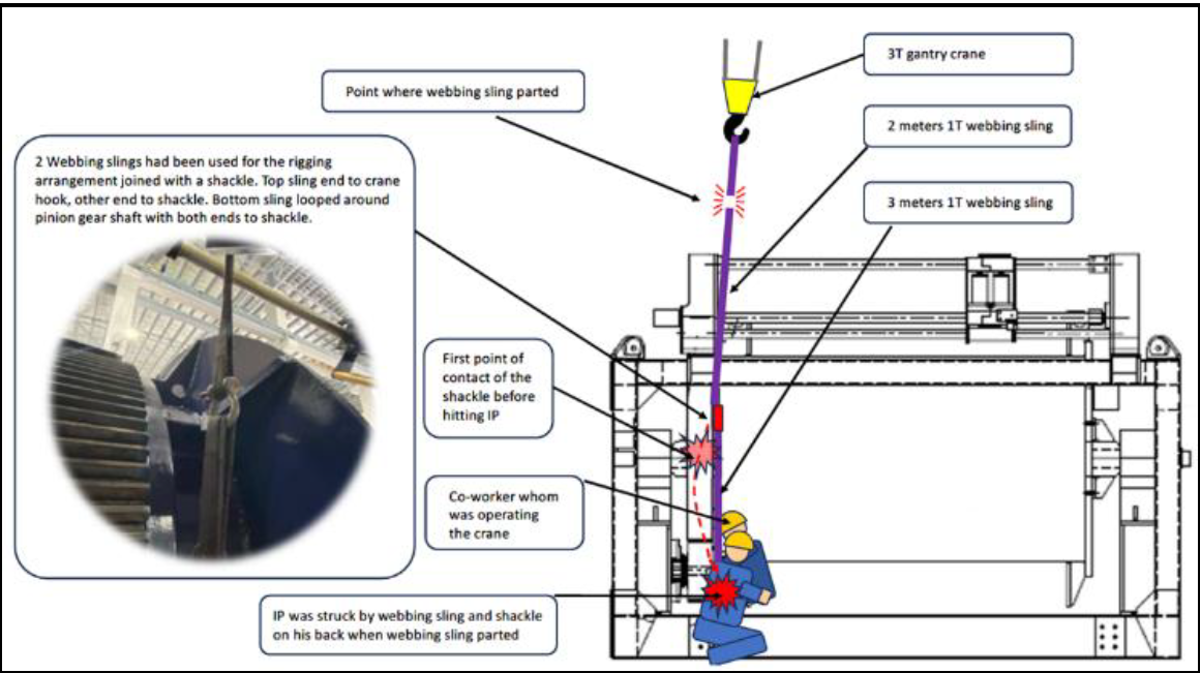

During the assembly of a LARS winch, an overhead gantry crane was being used for the final positioning of a component. The intent was only to use the crane for alignment of the component, rather than lifting, however excess load was inadvertently placed on the soft sling being used. This caused failure of the sling and the uncontrolled release of a connected shackle. The shackle struck a member of the work party again causing injury.

Lessons learned

While these two lifting activities were different, the investigations both identified common gaps related to operator training & competency, supervision, and understanding of line of fire risks.

- Only trained, competent, and experienced personnel should be involved in lifting operations.

- Supervisors need to actively supervise the work – and not be tempted to offer practical help or to join in.

- All personnel must be vigilant and keep themselves and others out of the line of fire.

- There is a shared responsibility for safety which exists between the supervisor – the person controlling the work and the people doing the work.

Members may wish to refer to

Related Safety Flashes

-

IMCA SF 08/09

19 June 2009

-

IMCA SF 02/15

5 February 2015

-

IMCA SF 05/21

11 February 2021

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.