Weld failure on Kirby Morgan KM17B 505-055 neck clamp

- Safety Flash

- Published on 30 July 2007

- Generated on 24 February 2026

- IMCA SF 06/07

- 1 minute read

Jump to:

A Member has reported that a weld on an eight-year-old Kirby Morgan neck clamp arrangement has failed.

What happened?

Kirby Morgan Dive Systems has indicated to the company that this may have been caused by either inadequate bead build-up on the weld or crevice corrosion.

In either case Kirby Morgan Dive Systems stated that underwater, this failure would not cause a catastrophic failure resulting in injury or death.

It also stated that this deficiency would be detected during the daily pre- or post-dive checks providing proper pre- and post-dive checks were being done and that there was no sure way to prevent failures of any component. However, proper maintenance and inspection would in most cases identify problems before they become dangerous.

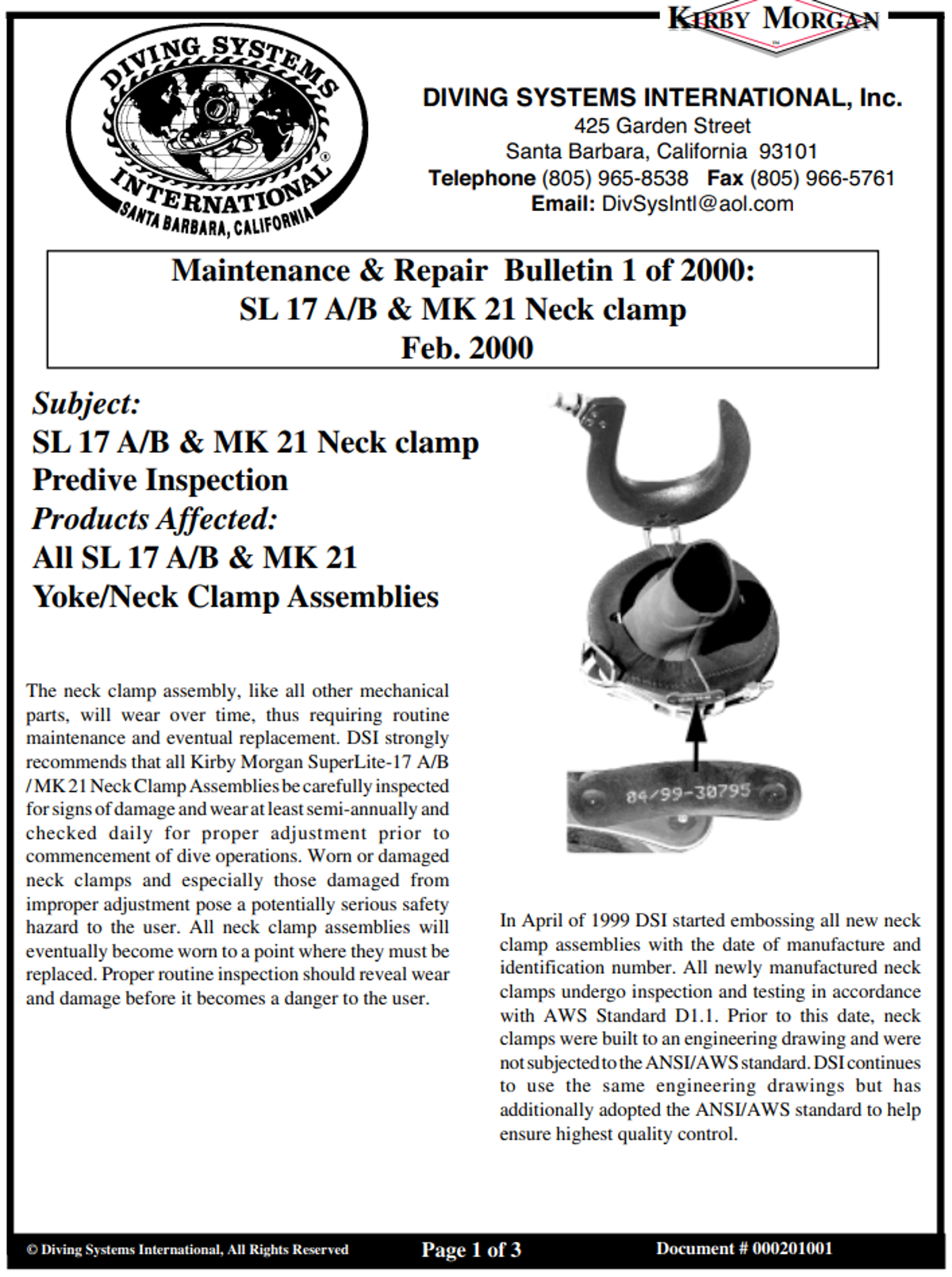

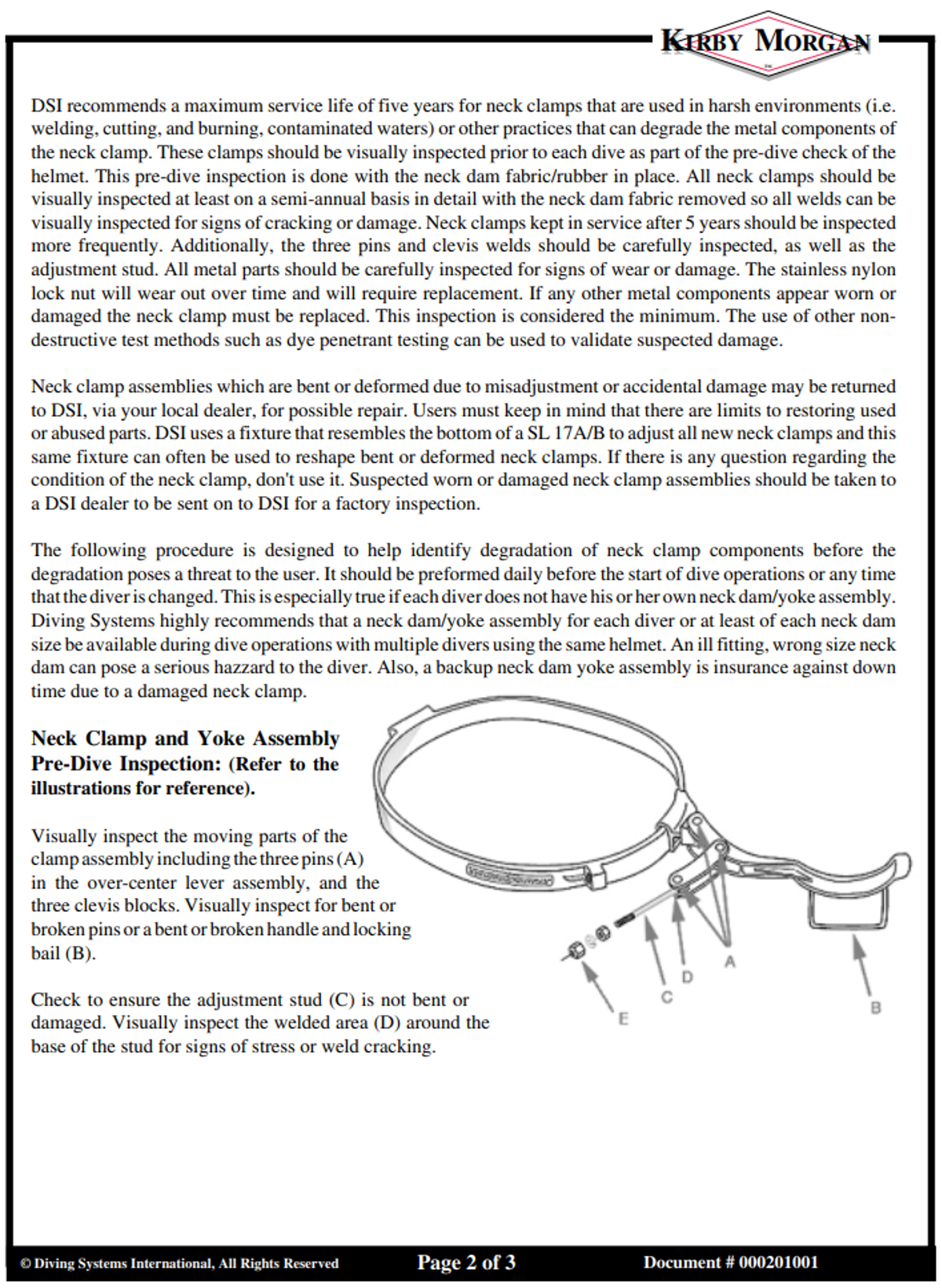

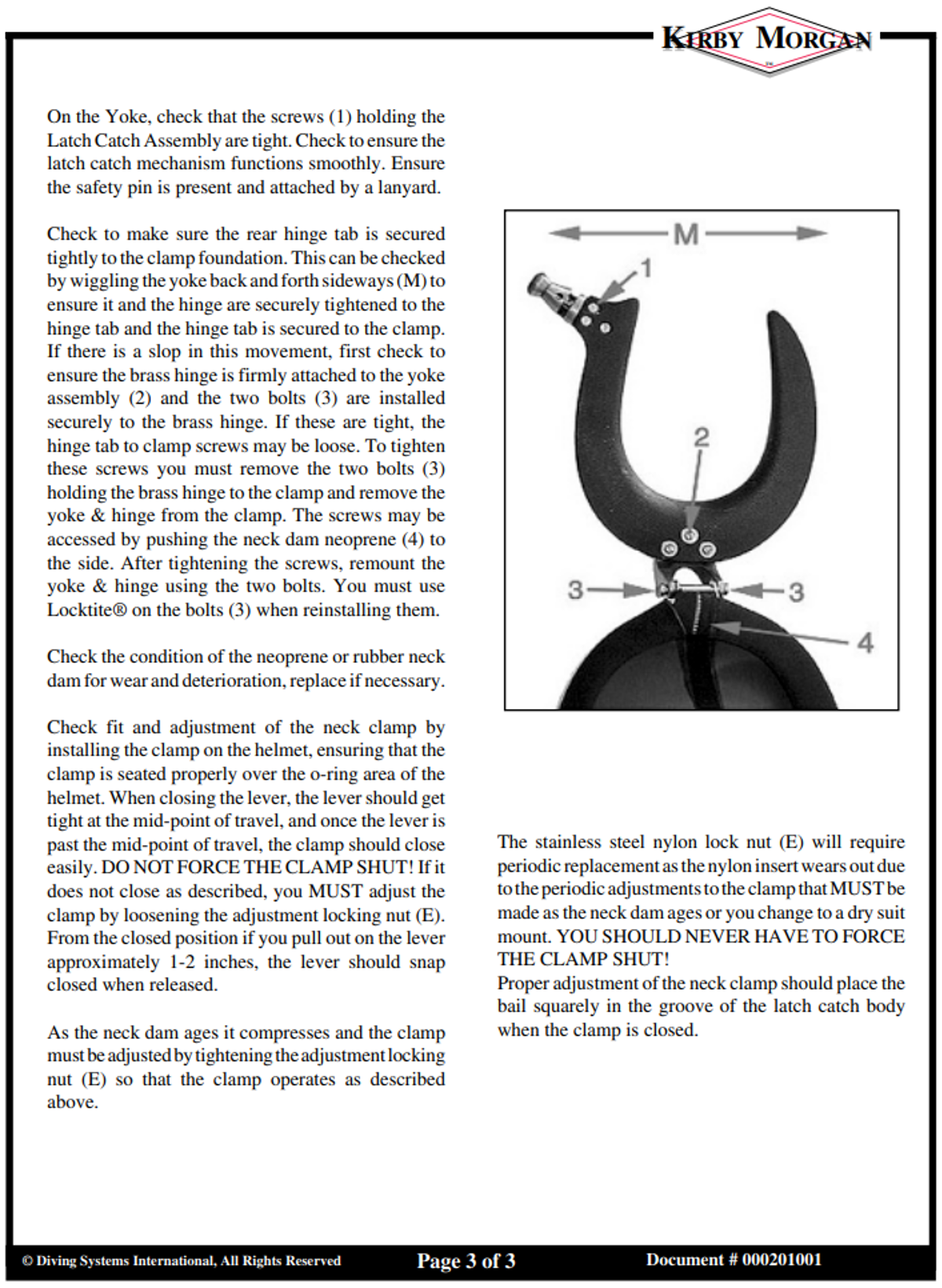

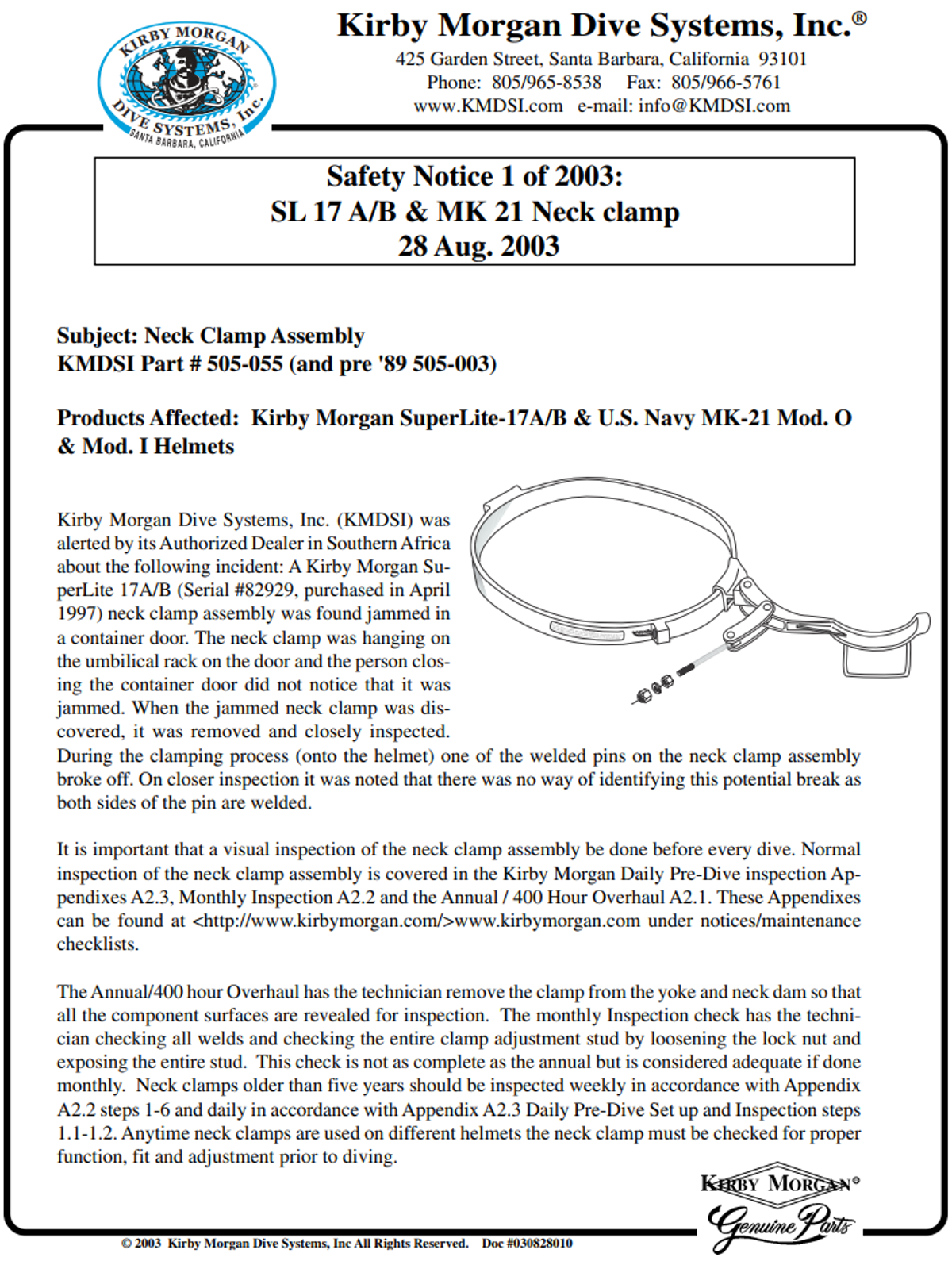

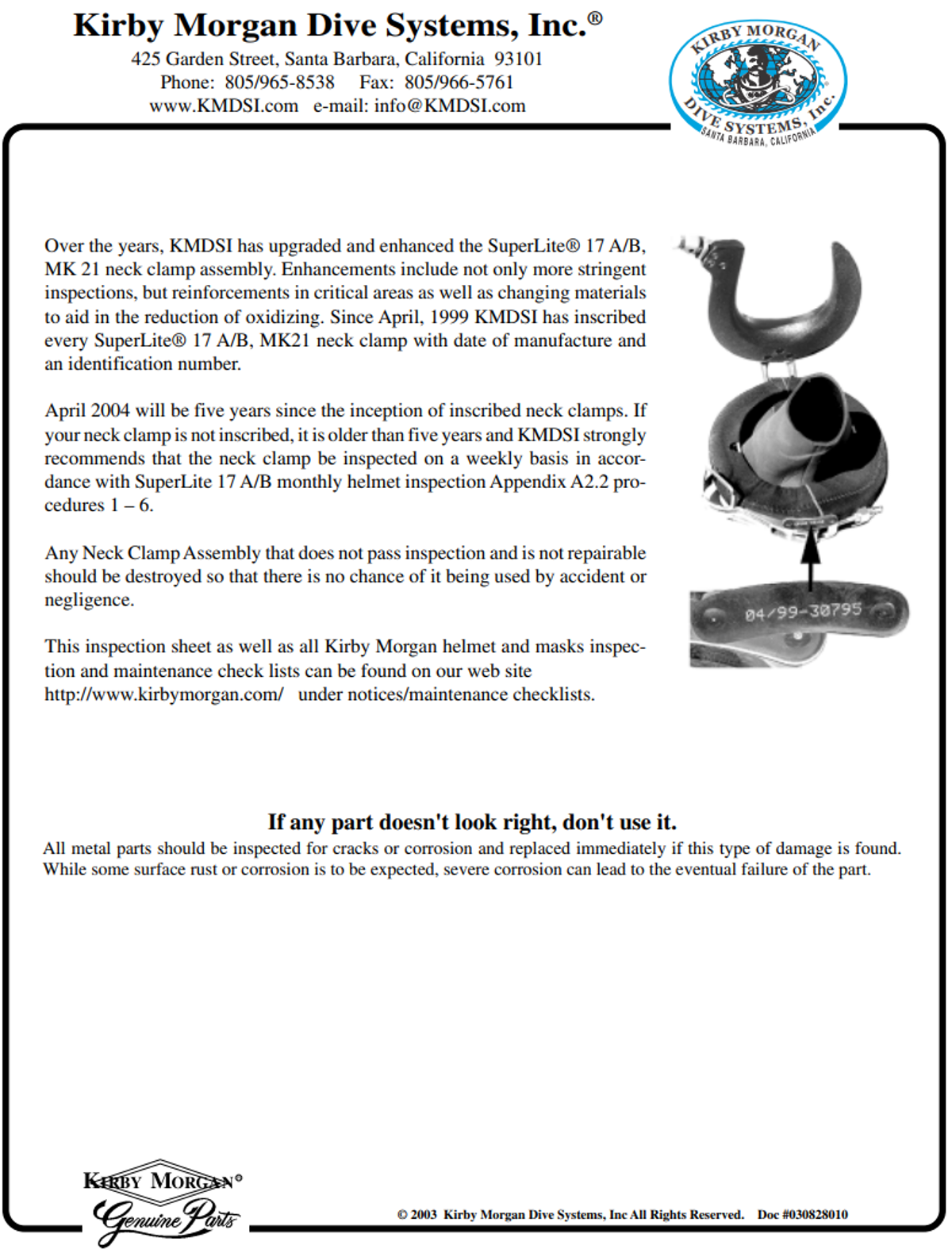

Two relevant bulletins issued by Kirby Morgan Dive Systems in 2000 and 2003 are attached.

These notices with other safety-related information are also available on the company’s website at kirbymorgan.com

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.