Near-miss: safety device (hard link) damaged during hot work

- Safety Flash

- Published on 27 September 2010

- Generated on 3 March 2026

- IMCA SF 06/10

- 2 minute read

Jump to:

A Member has reported an incident in which a rope access technician (RAT) damaged his safety equipment during hot work.

What happened?

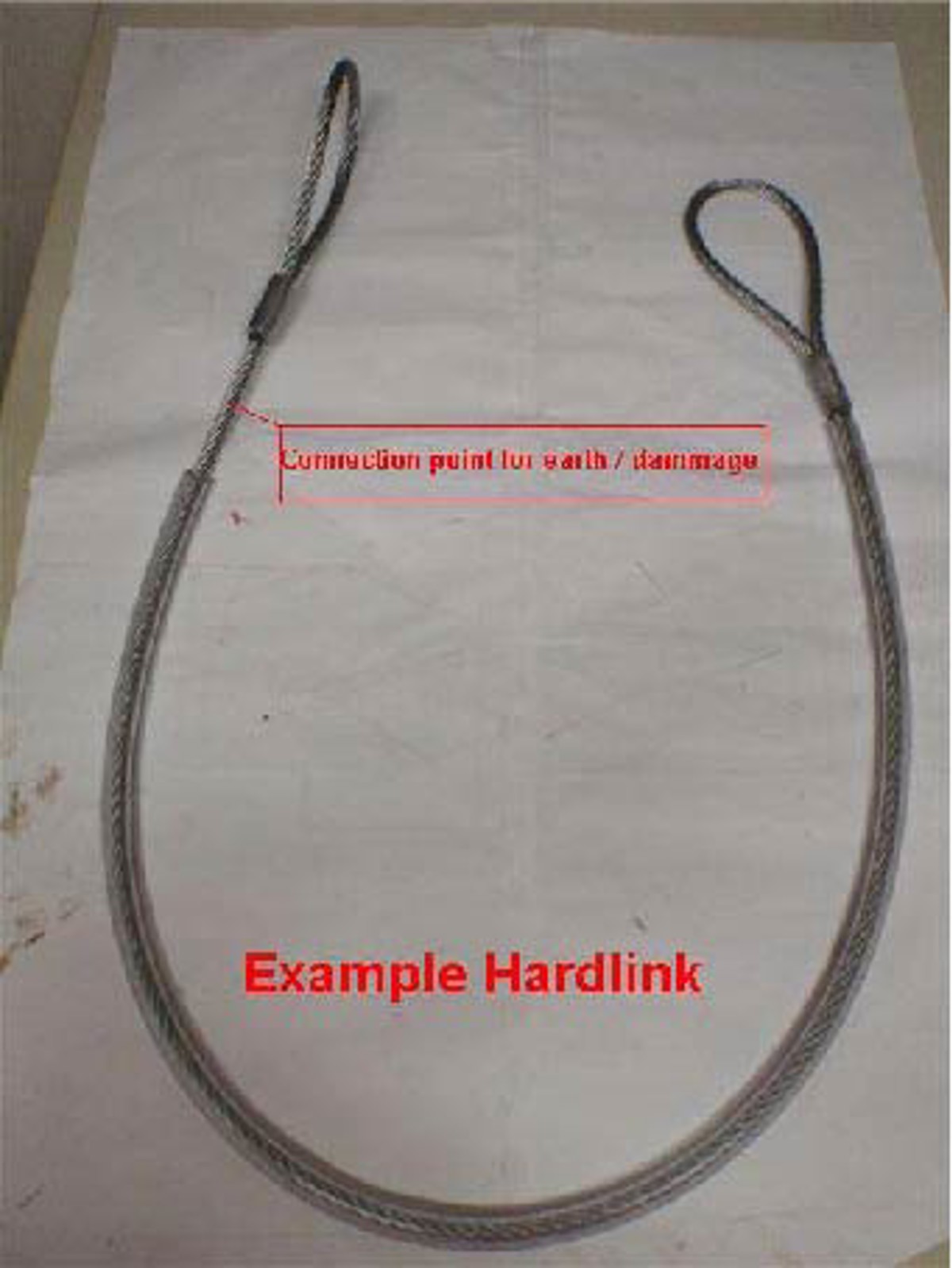

The technician was gouging out the weld connection around 8 metres above deck. He was working next to his two climbing ropes and was also secured with a hard link. This hard link was connected to the D-link of the technician’s harness and to a secure point above the technician.

At the moment the RAT opened the air flow to start gouging, water streamed out of the nozzle instead of air. This resulted in the technician instinctively pulling back the gouging torch. During this uncontrolled movement, the gouging torch connected with the stop descender – a steel part of the technician’s climbing gear. Since the technician was connected using a hard metal link to a beam on the platform, the technician’s metal climbing equipment made an electrical circuit to earth and current flowed from the gouging torch. As a result, three of the six strands of the hard link were burnt through.

The RAT descended safely to the walkway 8 metres below to check and replace the damaged equipment and subsequently was able to safely resume work. There were no injuries.

Following investigation, the following was suggested:

- Replace metal hard-link with a non-conductive nylon climber’s sling.

- Ensure water is drained out of air supply before use with gouging torch.

Typical metal ‘hard-link’ for rope access technicians

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.