Lead-acid battery explosion

- Safety Flash

- Published on 23 February 2021

- Generated on 14 February 2026

- IMCA SF 06/21

- 2 minute read

Jump to:

A lead-acid battery blew up when an engine was started.

What happened?

The incident occurred when, after conducting pre-start checks on a generator, the 2nd Engineer attempted to start the engine.

As the lube oil pressure reached start pressure and the starter motor engaged, there was a loud bang from behind the engine in the vicinity of the port side battery box.

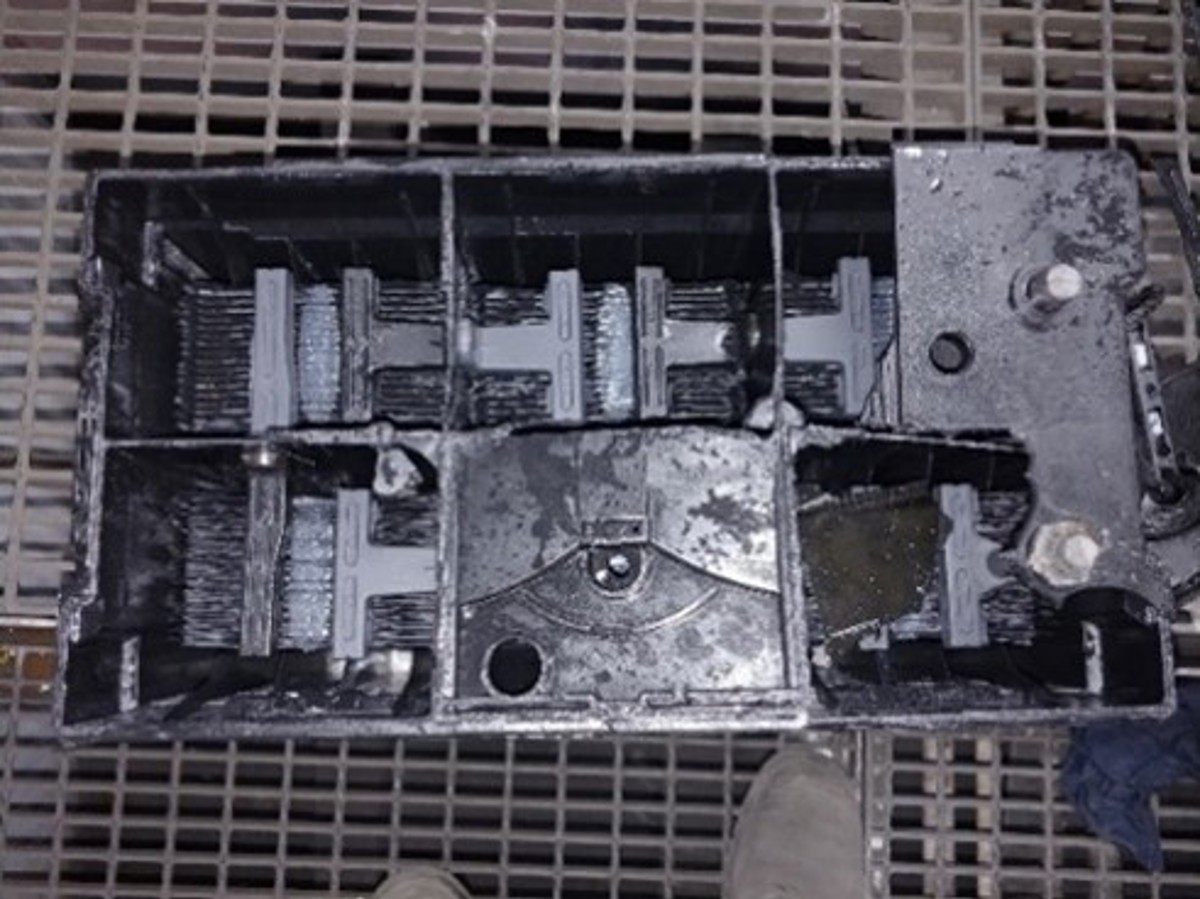

The 2nd Engineer on investigating, found that one of the batteries in the bank for the generator had suffered a critical failure resulting in the top of the battery case being destroyed.

He left the space immediately in case of release of hydrogen gas and woke the Chief Engineer to inform him of the incident.

What was the cause?

- The battery tie connection on the negative terminal had formed a hot joint. This would have ignited any excess hydrogen built up inside the battery box when the generator started.

- The manufacturer's instructions stated that the battery should not be used in hot environments (such as engine rooms).

Actions

- Consider replacing lead acid batteries with a type that does not release hydrogen when being charged, such as Absorbent Glass Mat (AGM) batteries.

- Check all battery terminals and connections.

- Follow manufacturer's instructions when installing batteries.

Related Safety Flashes

-

IMCA SF 34/20

16 December 2020

-

IMCA SF 19/19

12 August 2019

-

-

IMCA SF 12/19

28 May 2019

-

-

IMCA SF 05/13

4 April 2013

-

IMCA SF 11/03

1 September 2003

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.