Battery explosion during routine maintenance

- Safety Flash

- Published on 27 February 2023

- Generated on 23 February 2026

- IMCA SF 06/23

- 2 minute read

Jump to:

A Chief Engineer suffered minor injuries in a battery explosion when disconnecting a cable from the battery.

What happened?

The incident occurred onboard a harbour tug.

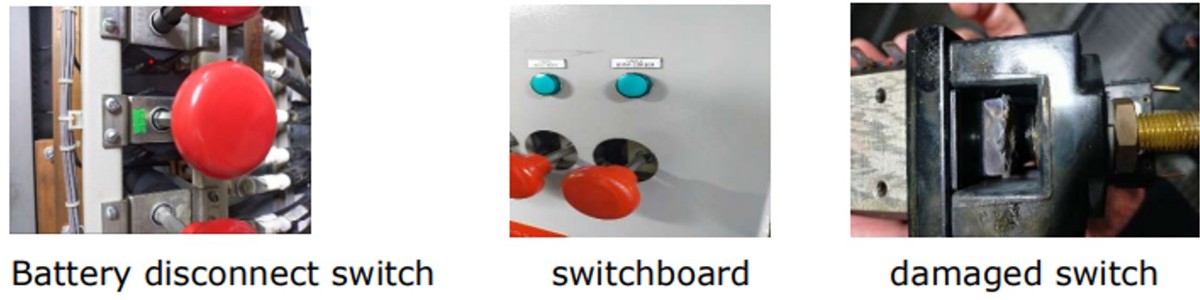

The Chief Engineer was planning to replace a battery disconnect switch that had failed. While disconnecting the positive terminal, both terminals were inadvertently short-circuited with a spanner and the battery exploded, injuring the Chief Engineer.

Operations were stopped, first aid was given, and the tug returned alongside. After assessment at hospital the Chief Engineer returned to the tug with only minor injuries. The tug was out of service for four hours.

What went right?

- The external power supply breaker was switched off.

- To be able to work on the switch safely, it was decided to disconnect the battery cables so the switch would be isolated from the battery 24VDC.

What went wrong?

The battery was inadvertently short-circuited with a spanner.

Lessons learned

- Protect battery terminals with plastic caps to avoid accidental contact.

- Ensure proper PPE (gloves, apron, face shield) is used when working on batteries.

- Consider the use of tools appropriate for battery handling.

- Changes to vessel's planned maintenance system:

- Follow manufacturer's recommendations for battery maintenance.

- Increase the frequency of battery maintenance inspection to gain better control of batteries in a poor state.

- Consider the installation of battery chargers with temperature sensors.

- Follow manufacturer's recommendations for battery maintenance.

Related safety flashes

-

IMCA SF 06/20

19 February 2020

-

-

IMCA SF 07/09

2 June 2009

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.