Failure of chamber door spindles and seals

- Safety Flash

- Published on 14 August 2007

- Generated on 3 July 2025

- IMCA SF 07/07

- 2 minute read

Jump to:

A Member’s diving support vessel (DSV) had recently completed a period of maintenance with some minor work on the saturation chamber system, which included door hinge realignment.

What happened?

During pressurisation of the divers, a leak was identified from the lock between the two occupied chambers. Pressurisation was halted at 5 msw and the system surfaced for repair. On completion of the repair the system was again pressurised when a different leak on the same door caused the pressurisation to be halted at 8 msw.

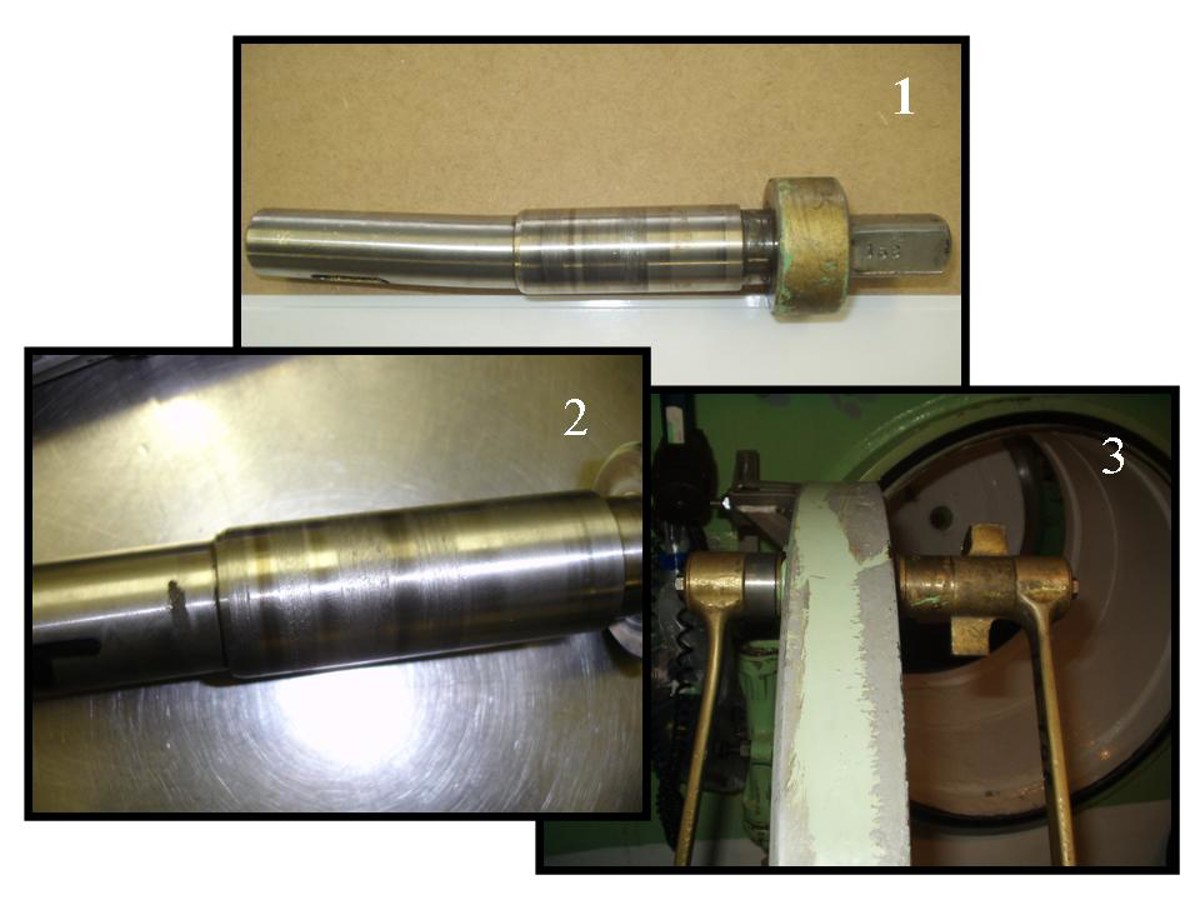

Both leaks were identified as being at the seals in the door spindle shafts that passed through the chamber doors to enable the retaining ‘dogs’ to be operated from both sides of the chamber door.

What were the causes?

The two leakages prompted an inspection of all the door spindles in the system, identifying the following:

- There was no history available on the spindles or seals, as they were not part of the planned maintenance system.

- Almost 70% of the door spindles were found to be unserviceable due to surface damage in the sealing area or bending of the shafts and required replacement.

1) Shaft damage; 2) Shaft surface damage; 3) Door spindles in place in chamber door

Lessons learnt

The following points are highlighted to members who have diving systems configured with spindles through chamber doors:

- The door spindles and associated seals should be identified as critical components.

- Inspection and replacement of the door spindles and seals should be included in the planned maintenance system.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.