Electric shock near-miss

- Safety Flash

- Published on 2 June 2009

- Generated on 21 February 2026

- IMCA SF 07/09

- 3 minute read

Jump to:

A Member has reported an incident in which an employee sustained an electrical shock whilst re-routing a work class remotely operated vehicle (ROV) tether.

What happened?

The ROV and tether management system (TMS) have separate electrical supplies and separate electrical circuits. At no point in the operation was power ever supplied to the ROV through the soft tether either deliberately or accidentally.

The ROV electrical power was isolated and locked off in order to allow ROV personnel to remove the tether from the vehicle. The TMS power supply was not locked off, in order to allow spooling to take place. Prior to removing the tether from the ROV, technicians used the correct test equipment and earthing equipment to ensure that there was no electrical power at the topside power distribution junction box and at the subsea ROV junction box.

During the rerouting operation the TMS single phase power was energised to pay out the tether. At this point an ROV technician received an electric shock to his wrist between his glove and coverall. On investigation it was found that, with the TMS single phase power energised, 360V AC was seen on the vehicle end of the ROV umbilical instrument conductors. When the TMS single phase was switched off it was then noticed the 360V AC had dropped to zero volts. All of the wiring was as per specification, no wires were crossed.

No injury was sustained and no medical treatment was required.

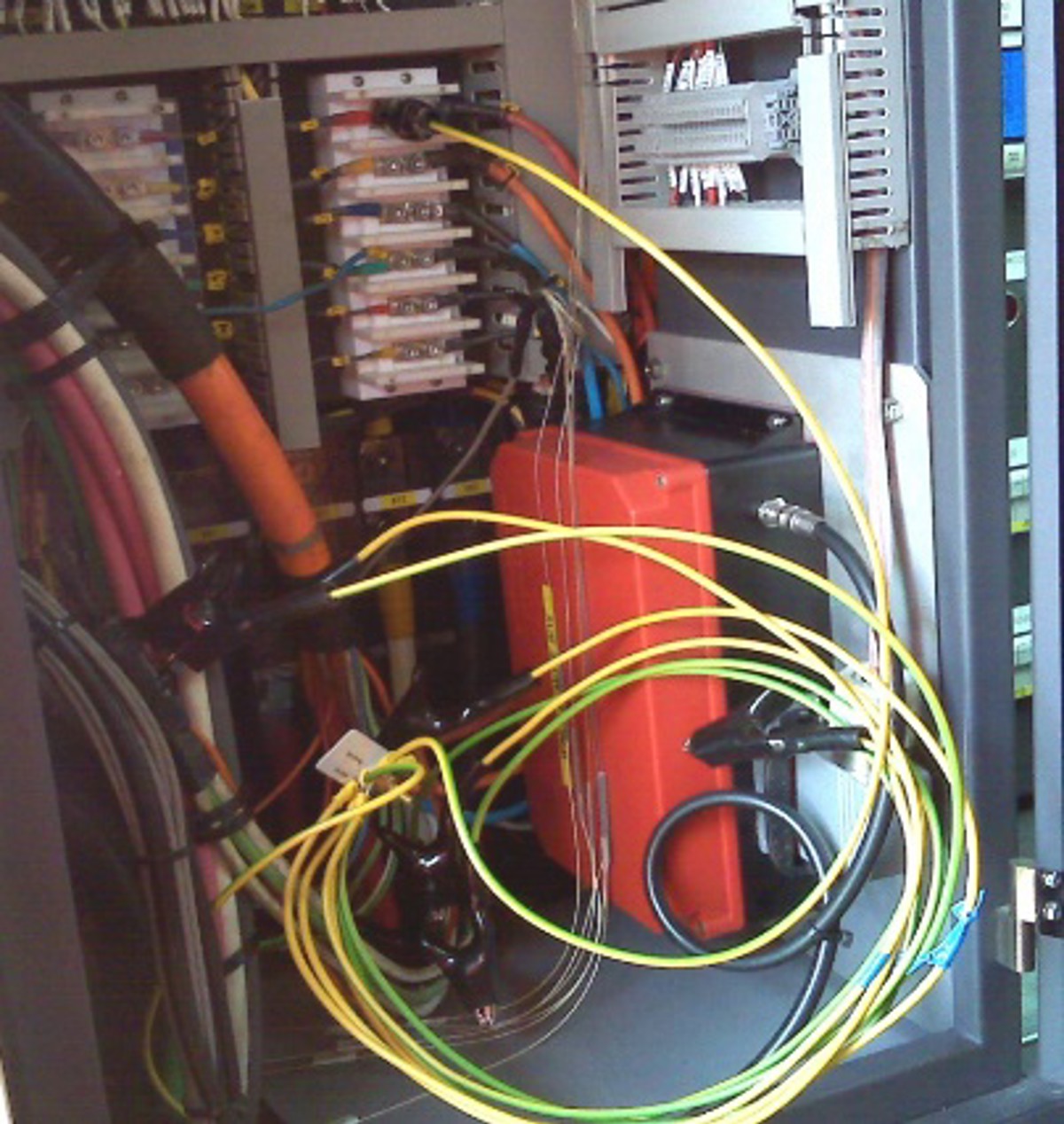

high voltage (HV) junction box with earthing equipment attached

What were the causes?

Following investigation, the following points were noted:

- A toolbox talk was carried out where the operation and safety aspects were discussed.

- The immediate cause of the electric shock was the ROV technician coming into contact with a conductor at the end of the ROV tether.

- This conductor, whilst isolated from a direct power source, was identified as having an induced voltage present. The voltage was induced in the main lift umbilical on the deck winch.

- One of the functions of the earthing equipment was to tie conductors to earth and eliminate any induced voltage that may be present. On this occasion, two of the clips of the earthing equipment had become dislodged. The ‘crocodile’ clip arrangement was found not to be a secure method of attaching such a safety critical device.

- Some of the persons involved with this earthing equipment had not fully understood the criticality of the equipment, particularly in the case of high voltage (3000 V) and a long umbilical (3300 m). Nevertheless, this equipment was correctly used and all appropriate procedures were followed.

- Personnel needed to be more aware of induced voltages and their potential to be fatal. The umbilical manufacturer confirmed that the induced voltage found in this tether was potentially fatal rather than superficial as some of the persons involved had thought.

Actions and lessons learnt

The company has made the following recommendations and corrective actions:

- Improve design of earthing equipment in such a way as to remove the possibility of inadvertent disconnection.

- Follow up with the manufacturer to include start up, induced voltage and isolation in training course material.

- Ensure all personnel working on work class ROV systems have completed HV training courses.

- Ensure signage is posted at all high voltage junction boxes warning of HV dangers and necessity to use appropriate earthing equipment.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.