Shackles in rigging assembly below required safe working load (SWL)

- Safety Flash

- Published on 19 July 2011

- Generated on 7 March 2026

- IMCA SF 07/11

- 1 minute read

A member has reported that during a recent a recent spot check on a lifting bridle it was identified that a 17T shackle had been fitted instead of a 30T shackle.

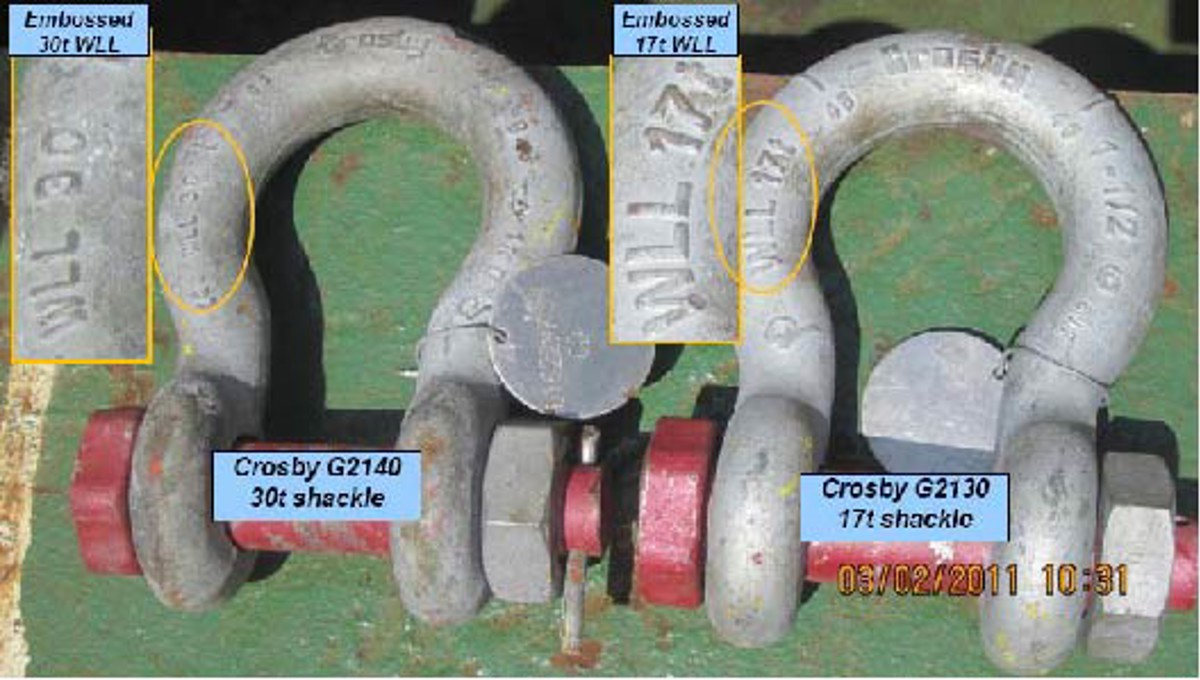

The preassembled lifting bridle included 3 x 30T shackles (Crosby G2140) and 1 x 17T (Crosby G2130) instead of 4 x 30T shackles. The certificate for the 17T shackle was cross checked against the identification number on the attached tag plate and showed the shackle SWL as 30T. The shackle was removed and replaced with a 30T shackle (30T working load limit (WLL) embossed).

Although the shackles are almost identical in size, differences in the material grades determine the WLL. Both the material grade and WLL are embossed on every shackle. It appears that an error was made during the certification process by the supplier where a 17T shackle had been certified (ID tag attached with common certificate number) as part of a batch of 30T shackles.

This unsafe condition reinforces the requirement to conduct a pre-use inspection of lifting equipment prior to commencing the lift.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.