Transferee stepping from gangway to staircase during rotation

- Safety Flash

- Published on 18 April 2019

- Generated on 3 March 2026

- IMCA SF 07/19

- 3 minute read

Jump to:

During extraction of working teams from offshore wind farm turbine towers in poor weather, a transferee found himself on a gangway as it disconnected.

What happened?

Weather and sea conditions deteriorated faster than was forecast; the decision was taken to extract personnel from a number of turbine towers.

Three teams were safely extracted from three towers. During the transfer of the fourth team, the last person to cross (the team leader) began his transfer. When he was approximately halfway across, an alarm sounded, and the traffic light turned to red. The transferee continued across the gangway, but as he reached the end of the gangway at the vessel end, the gangway reached its extension limit and self-activated auto disconnection.

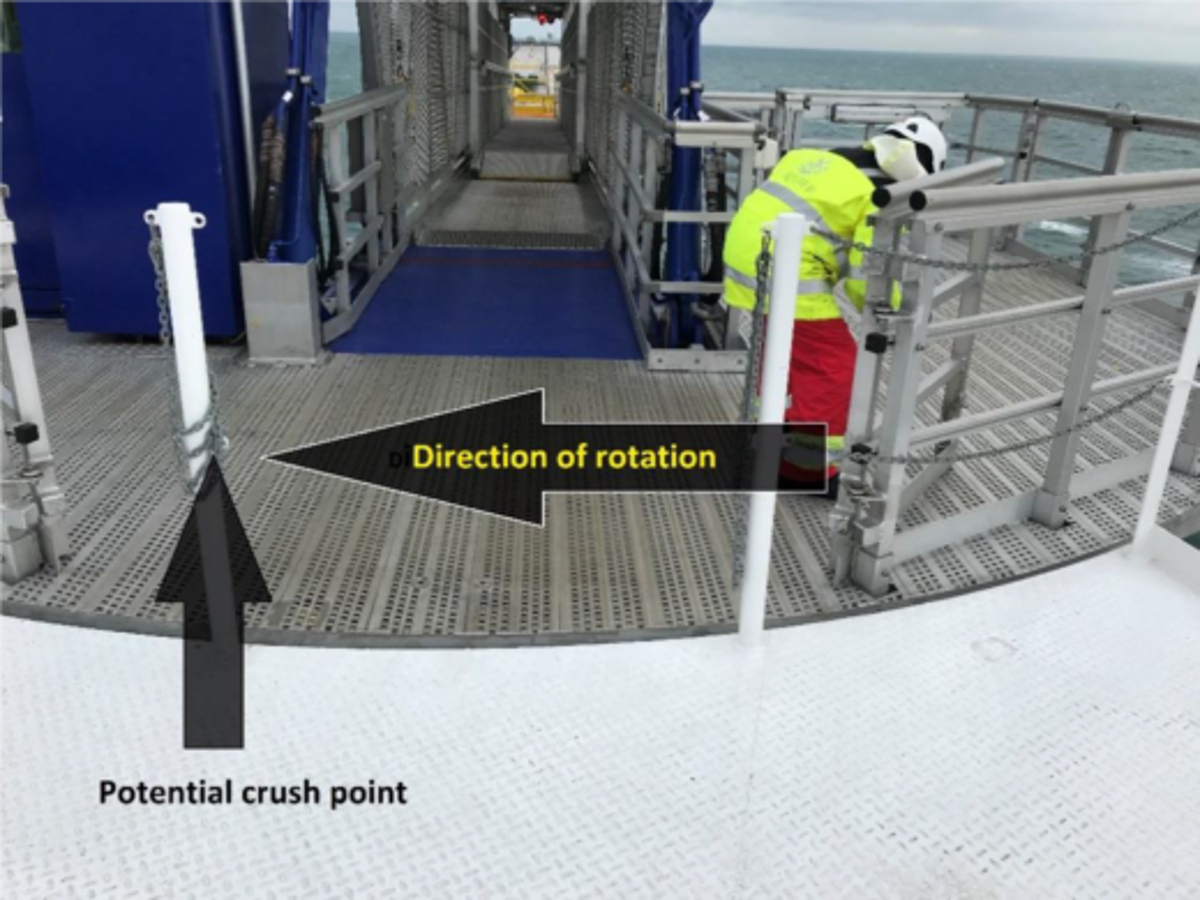

The equipment is programmed to slew to the right (towards stowed position on the vessel). As slewing occurred, the transferee continued forward to get off the gangway platform. While slewing, the guard rail of the rotating platform passed by the posts on the static part of the platform with approximately 19cm clearance between them. Since the transferee continued his transfer, he exposed himself to a potential crush hazard. The gangway completed its slew into its stowed position and the transferee safely exited the gangway platform.

The gangway safety induction video stated to return to vessel or brace in case of an alarm, depending on the transferee position on the gangway (static part of telescopic part).

Figure 1: Photo of gangway and railings

Figure 2: Screenshot from gangway operator’s induction video

What were the causes?

- The immediate cause was found to be failure to follow gangway instructions; the transferee continued to transfer from gangway to vessel.

- Root causes identified were:

- insufficient awareness and lack of risk perception of transferee

- insufficient design risk assessment – design of platform

- unclear instructions – induction gives ambiguous guidance on correct action if alarm sounds. Instructions are to transfer to vessel (when on static part of gangway), rather than continue to gangway platform and await instructions to continue transfer to vessel.

- insufficient awareness and lack of risk perception of transferee

- Contributing causal factors identified were:

- bad weather – wind noise contributed to confusion on the gangway

- unsafe construction – crush hazard was inherent to design of platform

- bad weather – wind noise contributed to confusion on the gangway

What actions were taken?

- The vessel Master noted that the post which forms part of the hazard is actually superfluous to operation and the necessary safety features of the gangway and platforms and could be removed without any effect. The post was removed.

- All crew were to refamiliarise with the gangway transfer safety video.

- Manufacturer of gangway contacted with suggestion to review/revise their design risk assessment with respect to position of poles on fixed platform in relation to proximity to gates on rotating gangway platform.

- A further lesson learned is that gangway instructions differ per gangway manufacturer/operator, which causes confusion amongst transferees.

Related Safety Flashes

-

IMCA SF 13/18

22 June 2018

-

-

IMCA SF 19/15

23 November 2015

-

IMCA SF 06/14

16 April 2014

-

IMCA SF 06/13

3 May 2013

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.