Failure of natural fibre rope in embarkation ladder

- Safety Flash

- Published on 4 March 2021

- Generated on 12 July 2025

- IMCA SF 07/21

- 3 minute read

Jump to:

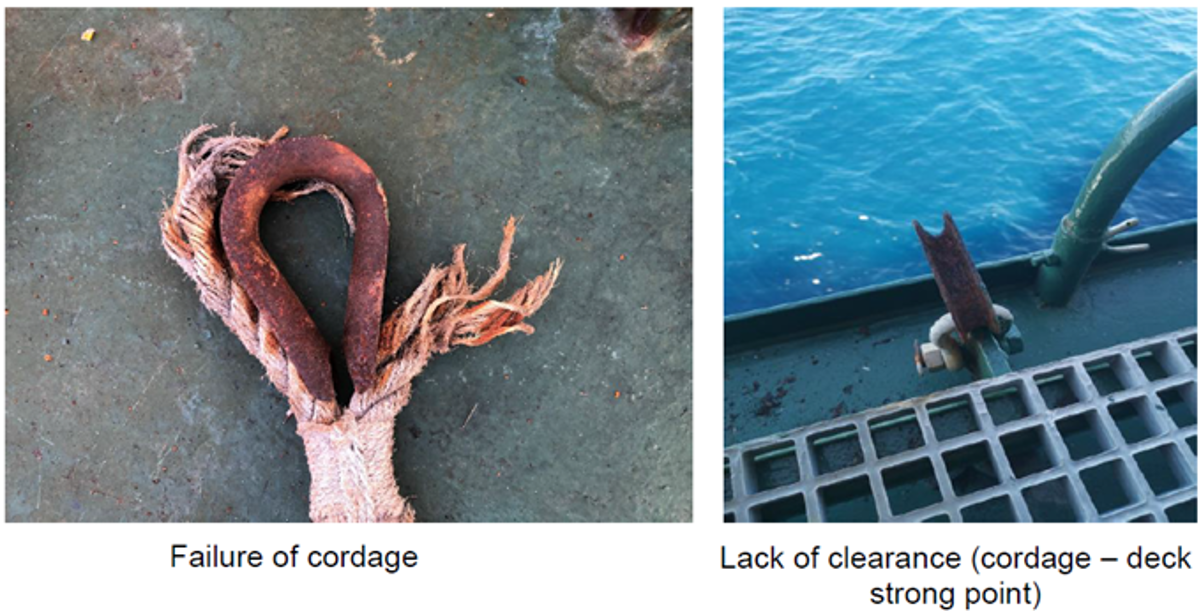

Planned inspection / replacement of a lifeboat embarkation ladder identified the total failure of the natural fibre rope at the securing thimble.

What happened?

The fibre rope at the anchor point securing thimble was worn through due to incorrect connection creating the potential for ladder failure on deployment.

Although natural fibre rope has properties that make it ideal for use in many marine applications, it is particularly susceptible to damage and loss of strength for several reasons, if it is not stowed and handled correctly.

What went wrong?

Investigation found that the failure was caused through abrasion due to the back of the eye being in contact with the metal deck strong point.

The anchor point was too small for the use of a shackle of enough size to provide clearance between the rope and deck strong point.

The rope failed during removal of the ladder, indicating the extent of the wear.

Actions

The inspection and maintenance of rope ladders should be part of the vessel planned maintenance schedule. A thorough inspection should be undertaken on a regular basis, and a visual check before and after use. The entire length of the ladder should be examined including all fixtures and fittings, considering the following points:

- Although the surface of the rope may appear to be in satisfactory condition, natural fibre rope may self-abrade from the inside. The lay should be opened at regular intervals along the rope to check for signs of wear.

- The presence of dark mould spots or a grey powdery substance within the lay of the rope may be an indication of rot or mildew, which is very difficult to eradicate.

- If the fibres on the surface appear to be weak or frayed and can be picked away easily, the rope may be suffering from sunlight or chemical degradation.

- Steps and chocks should be inspected for damage, cracks, wear, splits, sharp edges or splinters. Ensure slip resistant material applied to steps remains effective.

- Securing shackles should be inspected for corrosion, for size and suitability and shackle pin secured by means of a split pin or similar arrangement.

- Pad eyes should be inspected for damage or corrosion, and welds checked for excessive wear down or cracks.

Damage to or degradation of a natural fibre rope should be evaluated by an appropriately experienced crew member. If deemed necessary, or if any doubt exists, the ladder should be removed from service, repaired or replaced. Factors which may require such action could include:

- fraying, abrasion, cuts or signs of excessive wear

- deterioration or damage caused by chemicals, detergent or paint

- powdering between strands, rot or mildew

- variations in diameter size

- exposure to overloading or shock loads

- kinks which are difficult to remove.

Shackles should be replaced if wear or corrosion has reduced the diameter of the crown or pin by more than 10%. Pad eyes should be checked for cracks and excessive wear and be replaced or repaired in accordance with Class requirements.

Related Safety Flashes

-

IMCA SF 03/21

19 January 2021

-

IMCA SF 24/20

14 August 2020

-

-

IMCA SF 02/19

13 February 2019

-

IMCA SF 24/18

30 October 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.