Finger crushed under Tether Management System (TMS) protection guard

- Safety Flash

- Published on 13 March 2023

- Generated on 26 February 2026

- IMCA SF 07/23

- 2 minute read

Jump to:

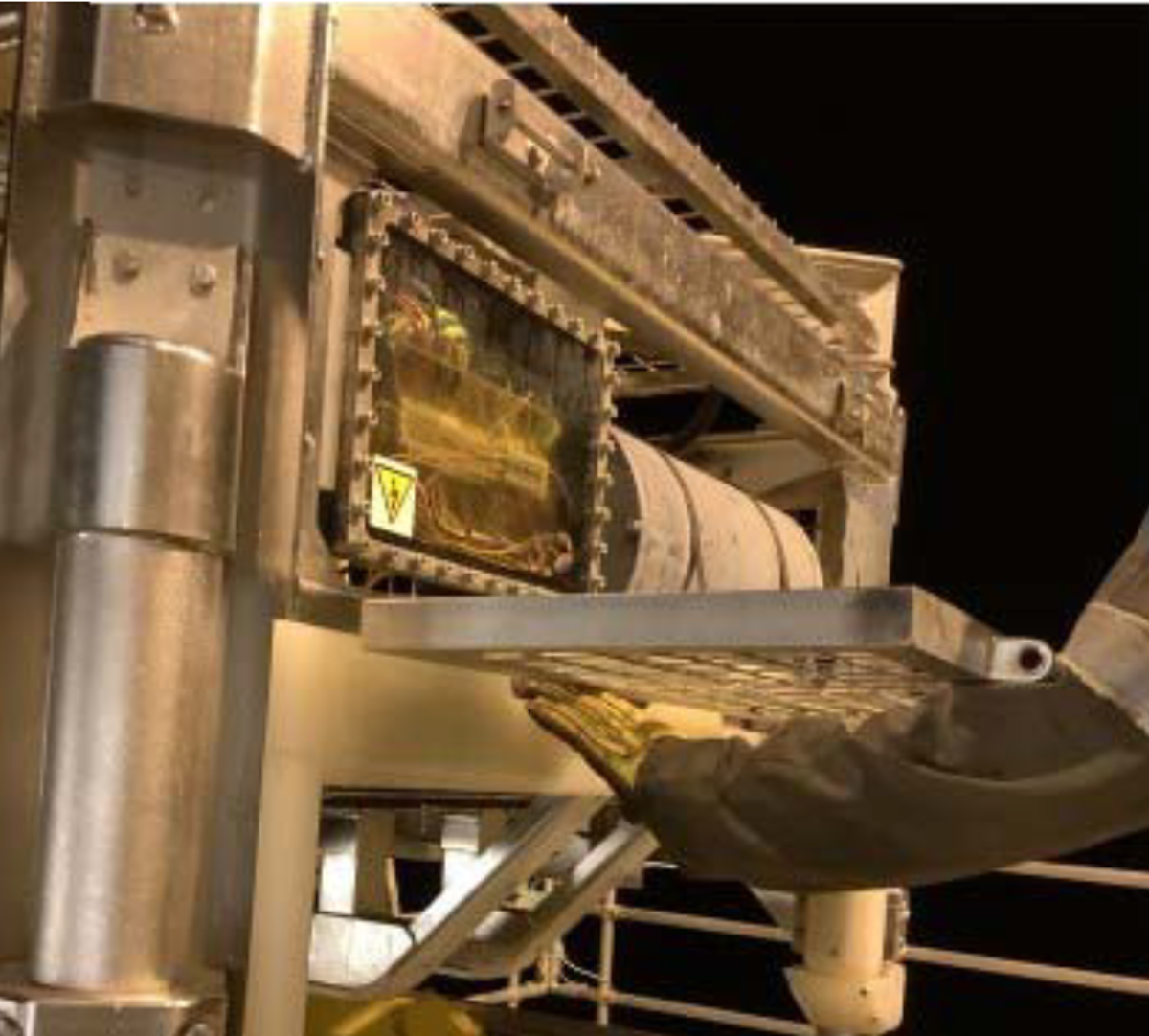

A worker suffered a crushed finger when the protection guard of a Saab Seaeye TMS8 Tether Management System fell on their finger.

What happened?

The worker was closing and securing the protection guard and lost grip on the guard.

The guard fell down and trapped the left ring fingertip between the guard and the TMS frame.

Upon removal of the glove it was identified the fingertip was damaged.

The injured person went straight to the medic, who verified that the injury warranted hospitalisation, and the injured person was taken to hospital onshore.

What went right?

- The injured person received medical help immediately and could be taken ashore for treatment quickly.

What went wrong? What was the cause?

- With the two top pins removed, the TMS guard can fall down if not safely supported – as when grip is lost.

- It was cold; there was no weather protection – cold hands.

- The worker was keen to complete the task in hand.

- The worker was not wearing the correct type of gloves.

- The task not fully risk accessed; there was no specific procedure/training to follow for guard removal.

Actions

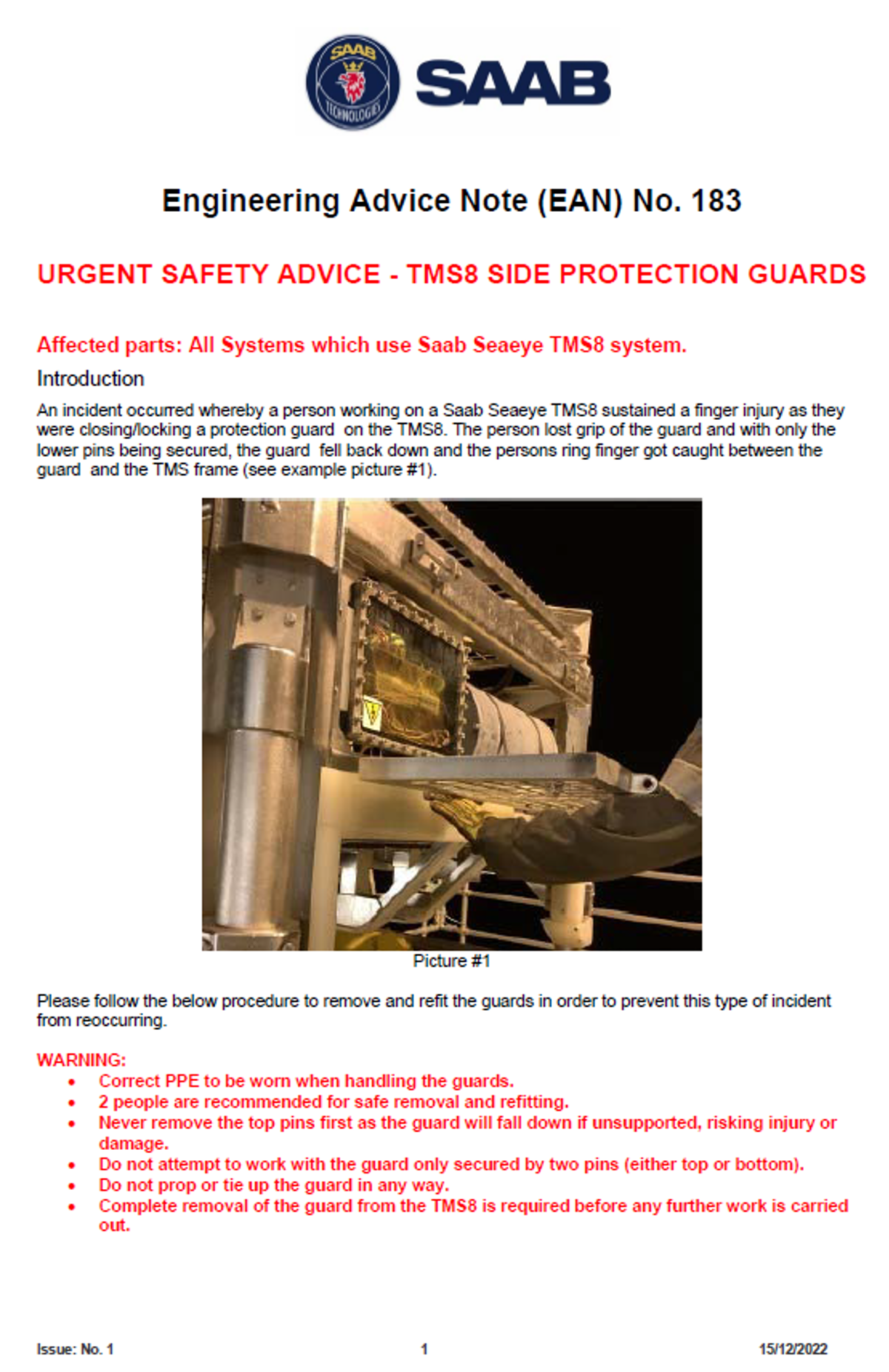

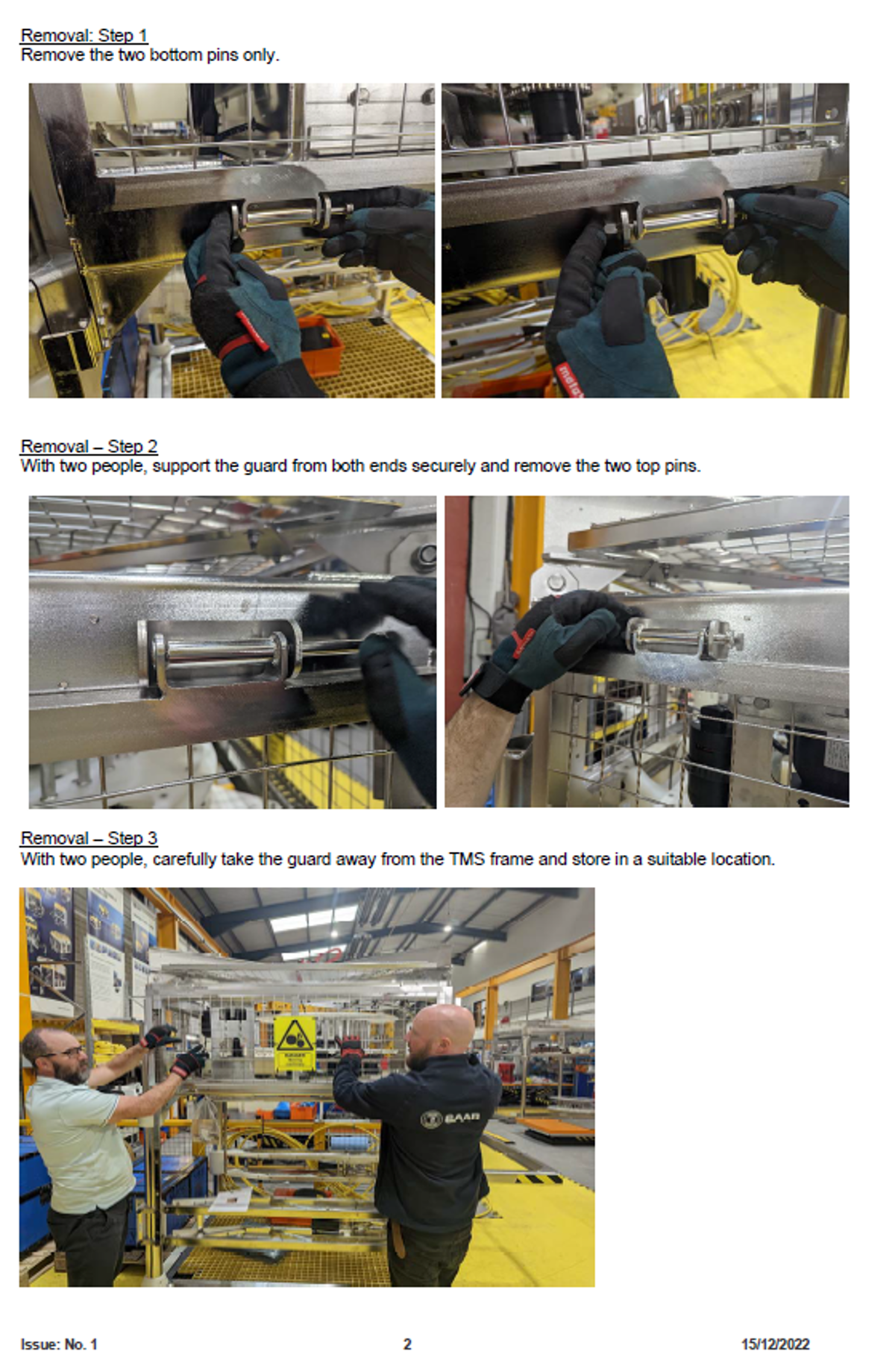

The design of guards and securing method is under review for potential improvements.

In the meantime a procedure for safe guard removal and refitting was generated and issued to all TMS8 owners as detailed in the bulletin here and copied below.

Related safety flashes

-

IMCA SF 17/21

16 June 2021

-

-

IMCA SF 08/16

13 April 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.