Person injured when chain hoist container failed at securing point

- Safety Flash

- Published on 27 March 2024

- Generated on 22 February 2026

- IMCA SF 07/24

- 2 minute read

Jump to:

An overhead electric chain hoist container/box weighing approx. 30kg fell around 0.8m onto a crew member.

What happened?

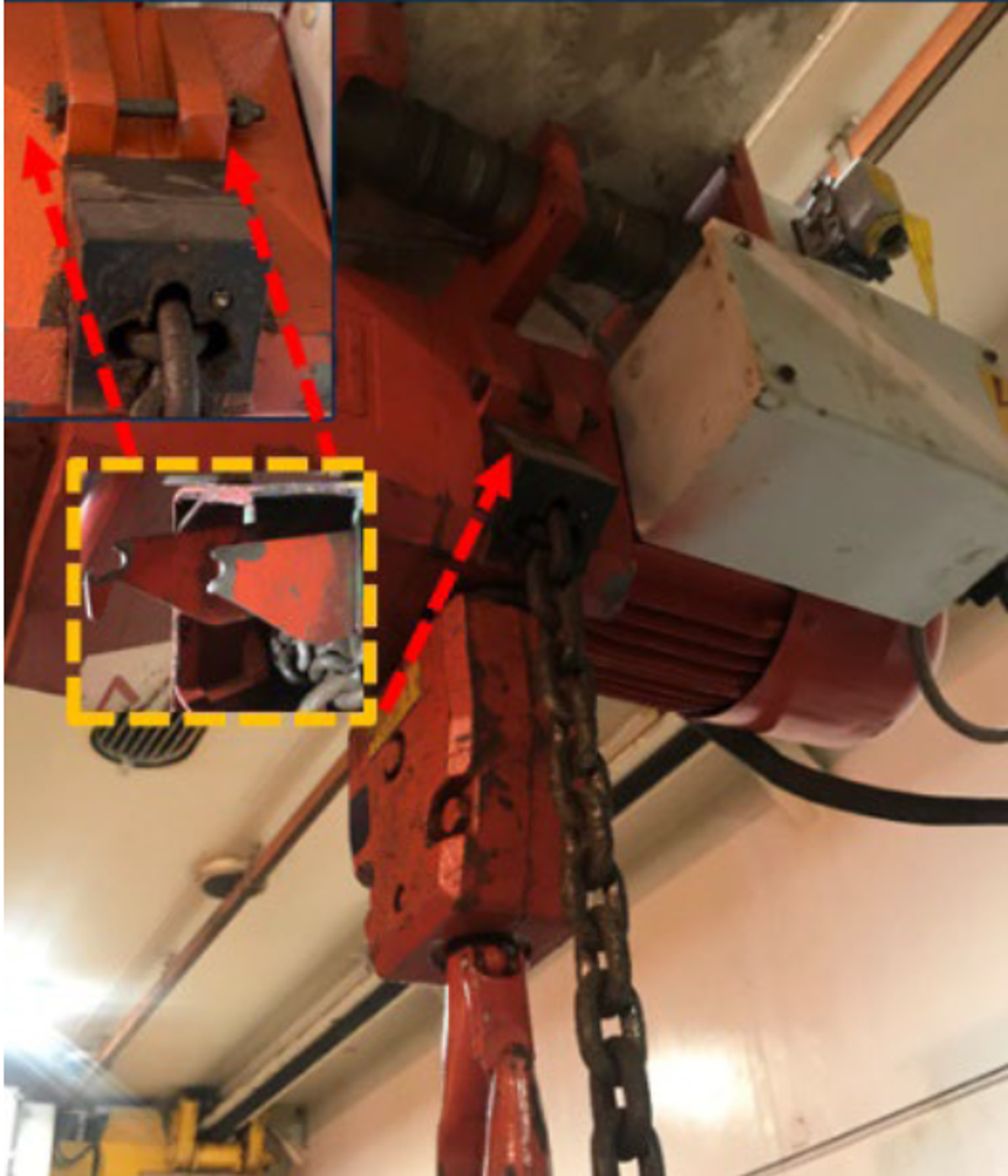

An overhead electric chain hoist container/box weighing approx. 30kg fell around 0.8m onto a crew member. The incident occurred whilst crew were working on adjustment of a heavy clamp used as part of a pipelaying operation. A permanently installed 3.2 Te SWL overhead electrical chain hoist, mounted above on a structural beam, was being used to support the clamp end. One of the securing points of the hoist failed, and the chain hoist container fell onto one of the crew present. It hit the right shoulder/back, causing contusion and bruising.

What went wrong?

- An improvement/alteration of the chain hoist container had been carried out locally without proper engineering calculation for the change (the original bag removed and a sheet metal box had been added).

- There was inadequate engineering/design: secondary DROPS retention had not been considered.

- There was inadequate maintenance/inspection: the inspection of exterior container was in the planned maintenance system, but it lacked important detail such as fixing point and wear.

Actions taken

- If you are required to make a change to a component, communicate this change with your supervisor/engineer to ensure the correct method and/or Management of Change is being applied.

- Amend planned maintenance system to include regular inspection of the chain container to ensure hardware (brackets, links, fasteners and other supports) are in good condition and replace any parts of hoist showing wear or damage – BEFORE using the hoist.

- Check of any similar hoists elsewhere; install secondary retention where required.

Related Safety Flashes

-

IMCA SF 23/21

19 August 2021

-

-

IMCA SF 20/20

6 July 2020

-

-

IMCA SF 12/20

31 March 2020

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.