Fall from height

- Safety Flash

- Published on 19 June 2009

- Generated on 28 February 2026

- IMCA SF 08/09

- 2 minute read

Jump to:

A Member has reported an incident in which a person was injured in a fall from a different level.

What happened?

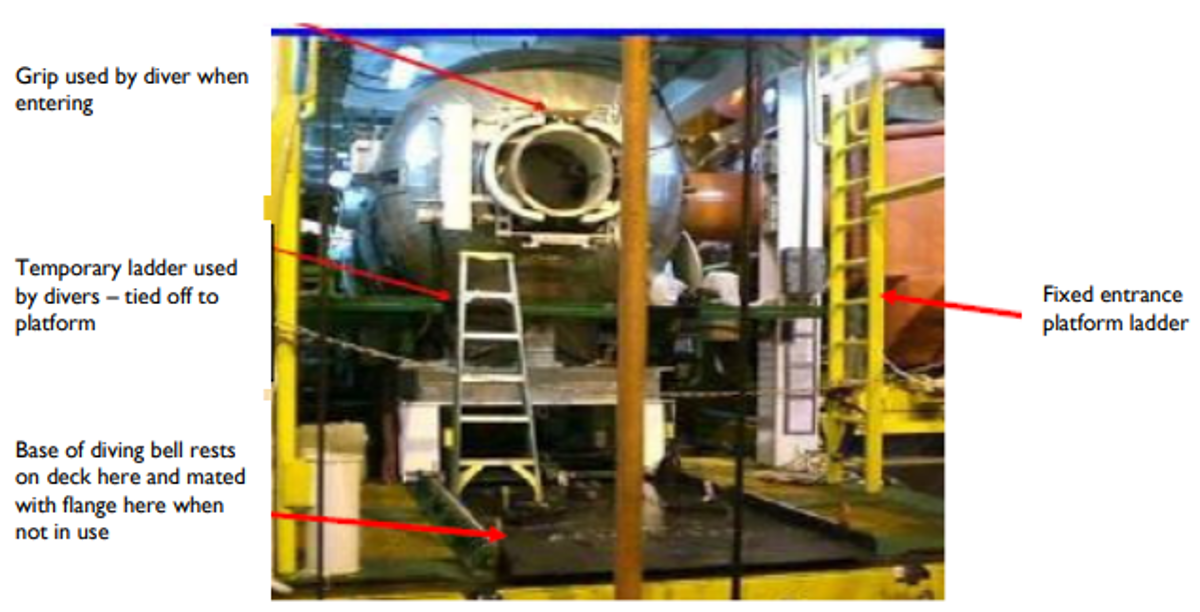

A saturation diver used the transfer under pressure (TUP) access hatch to come out of the saturation chamber while unloading equipment. To re-enter the chamber the diver held on to the top dogging bar of the chamber. The dogging bar rotated towards him causing him to lose his grip and fall approximately five feet on to the bell skid leading to muscle contusion and hairline fractures of his right forearm and right thigh.

What were the causes?

Further investigation revealed that:

- In normal circumstances the presence of the diving bell at this TUP access hatch made access and egress safe. When the diving bell was removed, there was less edge protection around the platform.

- The injured person did not recognise the lack of protection and increased risk of falling.

- The injured person used an incorrect handle (dogging bar) to pull himself into the chamber.

Saturation chamber from which diver fell

Lessons learnt

The following recommendations were made:

- Reinforce the importance of management of change procedures.

- Ensure the correct fixed handholds are used when accessing or exiting a saturation chamber.

- Ensure all relevant personnel are aware of the location and use of the correct handholds.

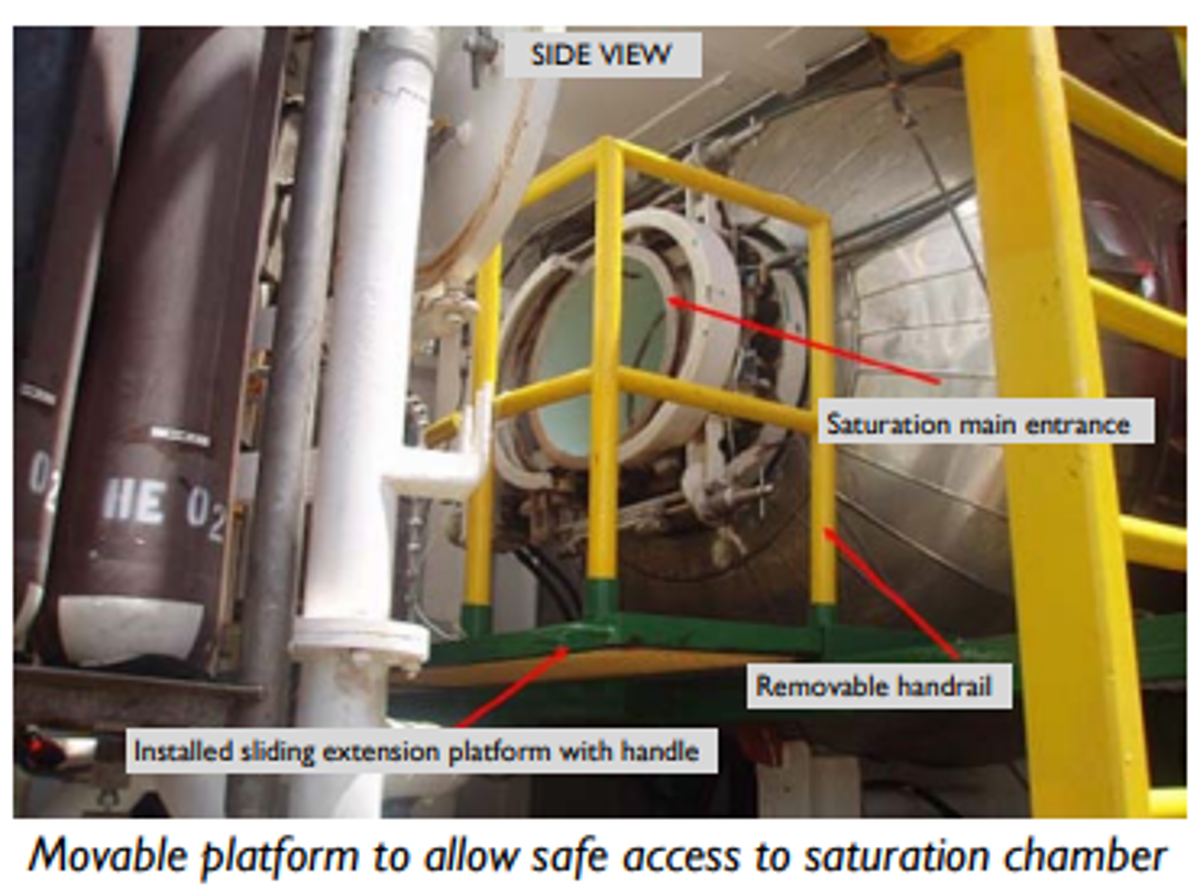

- Construct a removable platform with additional edge protection to facilitate access to and from the chamber when the bell is not present (see second picture).

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.