Hydrogen Sulphide (H2S) detected onboard vessel

- Safety Flash

- Published on 29 April 2025

- Generated on 24 February 2026

- IMCA SF 08/25

- 3 minute read

Jump to:

Several persons reported to bridge about a smell of septic or rotten eggs that was present all over the vessel. Hydrogen Sulphide (H2S) was suspected.

What happened?

A toolbox meeting was held on the bridge at which the risks associated with H2S were discussed.

The crew, equipped with gas detectors, started to investigate where the smell was coming from both inside and outside. No respiratory PPE was used. This was based on that the smell was noticeable all over the vessel, and that there was no indication of any gas before they started searching for the source. Last time vessel the same type of smell was experienced, this was caused by wind direction and ventilation from the sewage tank.

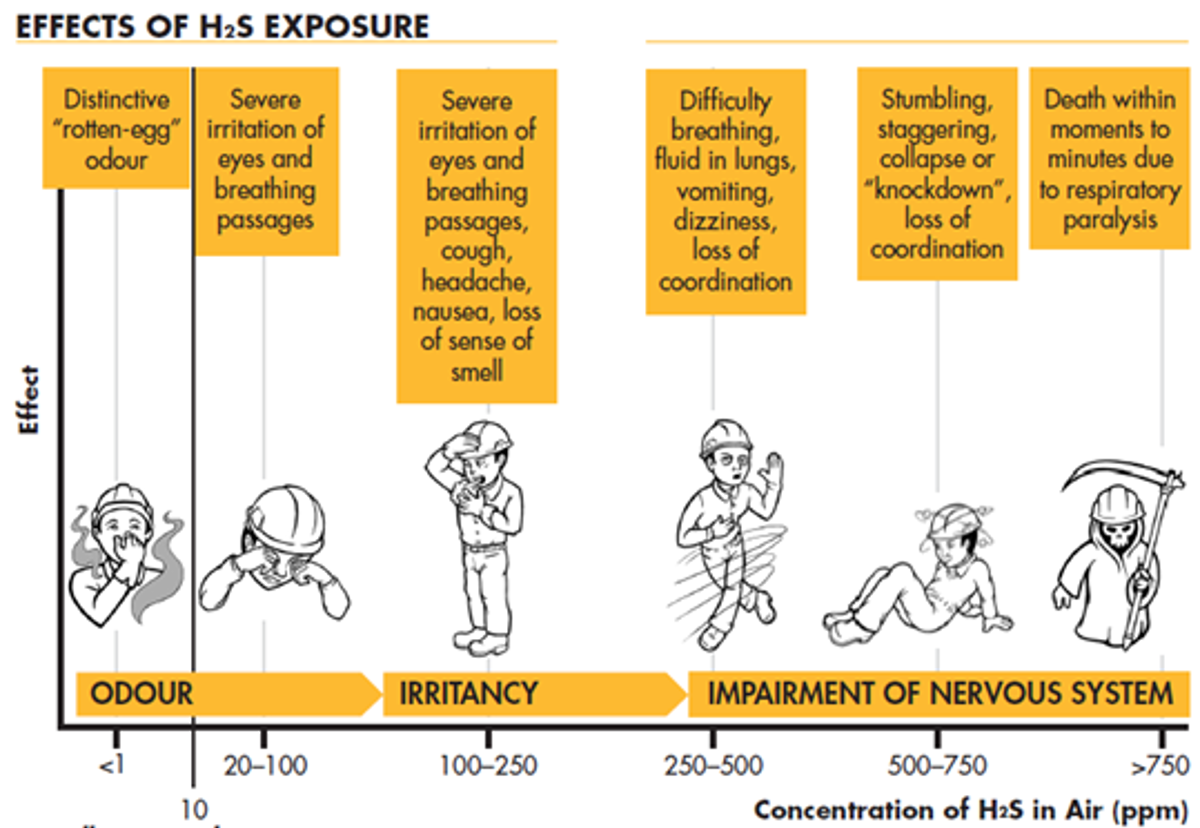

During investigation, a level of H2S of 170ppm was measured in the Grease Trap room. No gas was detected by gas detector in other areas onboard, only a smell. The H2S in the Grease Trap room came from the drain under the sink because the water trap was dry.

H2S was detected in the ventilation from the sewage/grey water tank, in the ventilation and not the surrounding area. The smell came from the sewage/grey water tank through multiple drains where water traps were dried out onboard in different areas.

What went wrong?

- Internal H2S emergency procedures not fully followed nor fully covered the actual situation.

- Breathing equipment or respiratory mask not used.

- No documented risk assessment after detection of H2S.

- Routines or procedure to flush grey water tank after maintenance of sewage plant were only partly followed.

- Routines to make sure that drain water traps don’t dry out, were not fully followed.

What was the cause?

- Sewage was being re-routed due to maintenance of the sewage treatment plant.

- Residues in sewage/grey water caused a build-up of H2S.

- Several drains where water traps were dried-out caused a “smell” detection of H2S.

What lessons were learnt

- Internal procedures do not fully cover every different scenario. Actions onboard should be based on continuous risk evaluation and locally made decisions.

- The importance of use of PPE in these situations. Even though this was “all over” the vessel, the crew searching for the source had a higher risk of being exposed to gas and could have exposed themselves to danger.

- Carefully check the health of crew that have been exposed to any gas.

Actions

- Amended or established procedures:

̶ To flush of grey water tank after maintenance of sewage plant

̶ To ensure that drain water traps don’t dry out - Reviewed H2S emergency procedures.

Related Safety Flashes

-

IMCA SF 32/21

25 November 2021

-

IMCA SF 12/24

18 June 2024

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.