Possible choking incident – diver’s helmet

- Safety Flash

- Published on 1 October 2004

- Generated on 9 February 2026

- IMCA SF 09/04

- 2 minute read

Jump to:

While performing a task during a saturation dive, a man inhaled a 45mm diameter neoprene component from a diving helmet.

What happened?

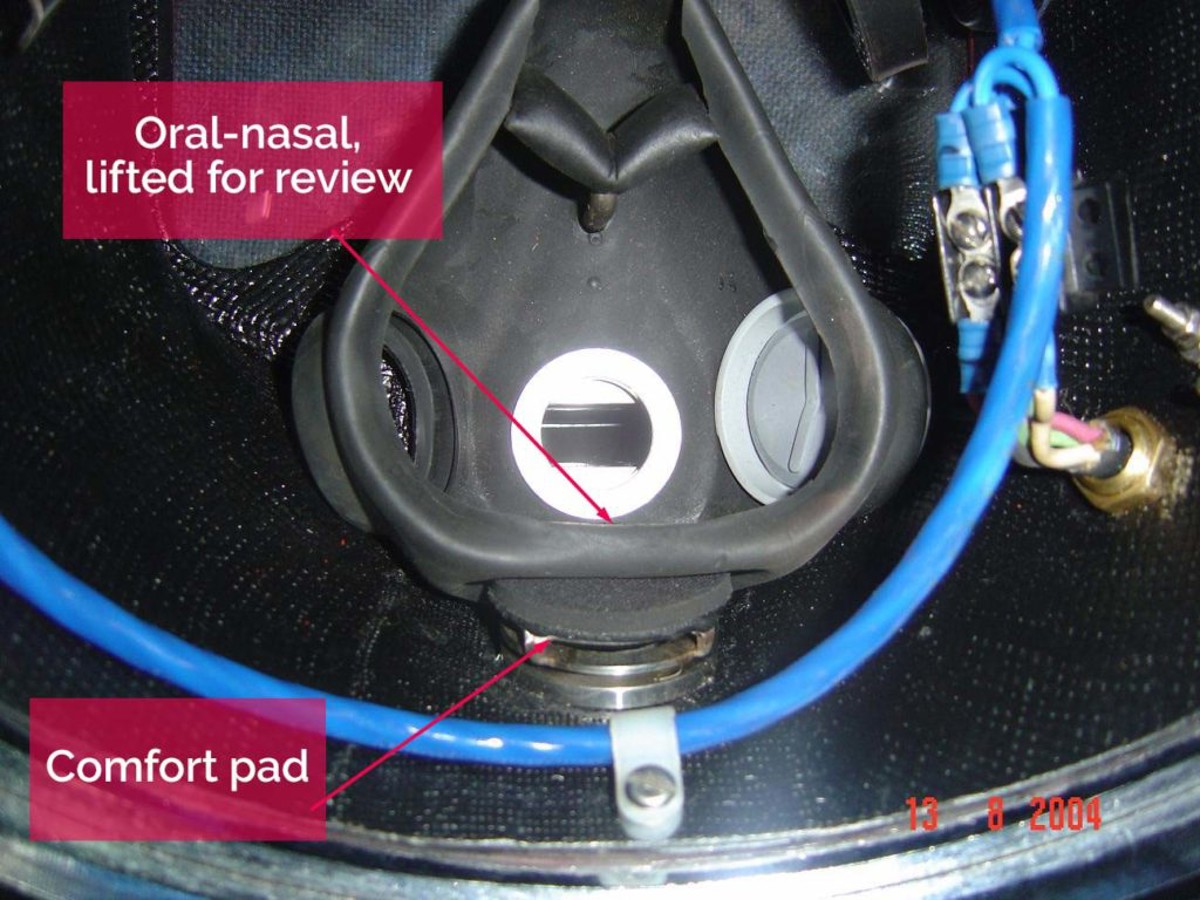

The component has been identified by the supplier as a ‘comfort pad’, which had been installed to protect the diver’s face from abrasion and cold.

As can be seen in the photograph the part is located on top of the retaining nut at the bottom of the oral nasal piece, in close proximity to the diver’s mouth. In this incident a choking incident was avoided as the part was caught in the diver’s teeth during inhalation. The cause of the detachment appears to have been a loss of bonding from the adhesive which attaches the two components.

The supplier of the helmet was notified and they have advised that a ‘Correct Memo’ is to be issued to the manufacturer ASAP. The manufacturer advised the application of an approved wet suit cement to reattach the pad.

The company concerned advised the supplier that the component was not listed on the parts list, nor mentioned in the checklist in the product manual. The relevant section however, although not specific to the component in question, gives clear instruction as to the preparation prior to the donning of the hat. The first statement is as follows:

“‘The helmet should be checked thoroughly before each mission. This should be done well in advance of the dive in order to be able to carry out any repairs or adjustments that may be necessary”.

In close proximity to the relevant part in the manual, the instructions state:

“Check that the oral-nasal mask (44), the nose block device (43), and the oral-nasal retainer (121) are properly attached.”

The company concerned is in contact with the supplier and manufacturers of the equipment, and there may be a following note to advise of progress. The company has recommended that close scrutiny is given to checking this part and other similar components prior to every dive. It has advised its crews that a spare nut with the pad attached will be made available for quick turn-a-rounds should this be required.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.