Malfunction of Kirby Morgan B17 side block non-return valve

- Safety Flash

- Published on 29 July 2005

- Generated on 2 July 2025

- IMCA SF 09/05

- 2 minute read

A Member has reported that it has experienced several failures of KM B17 side block non-return valves which have had little or no in-water service.

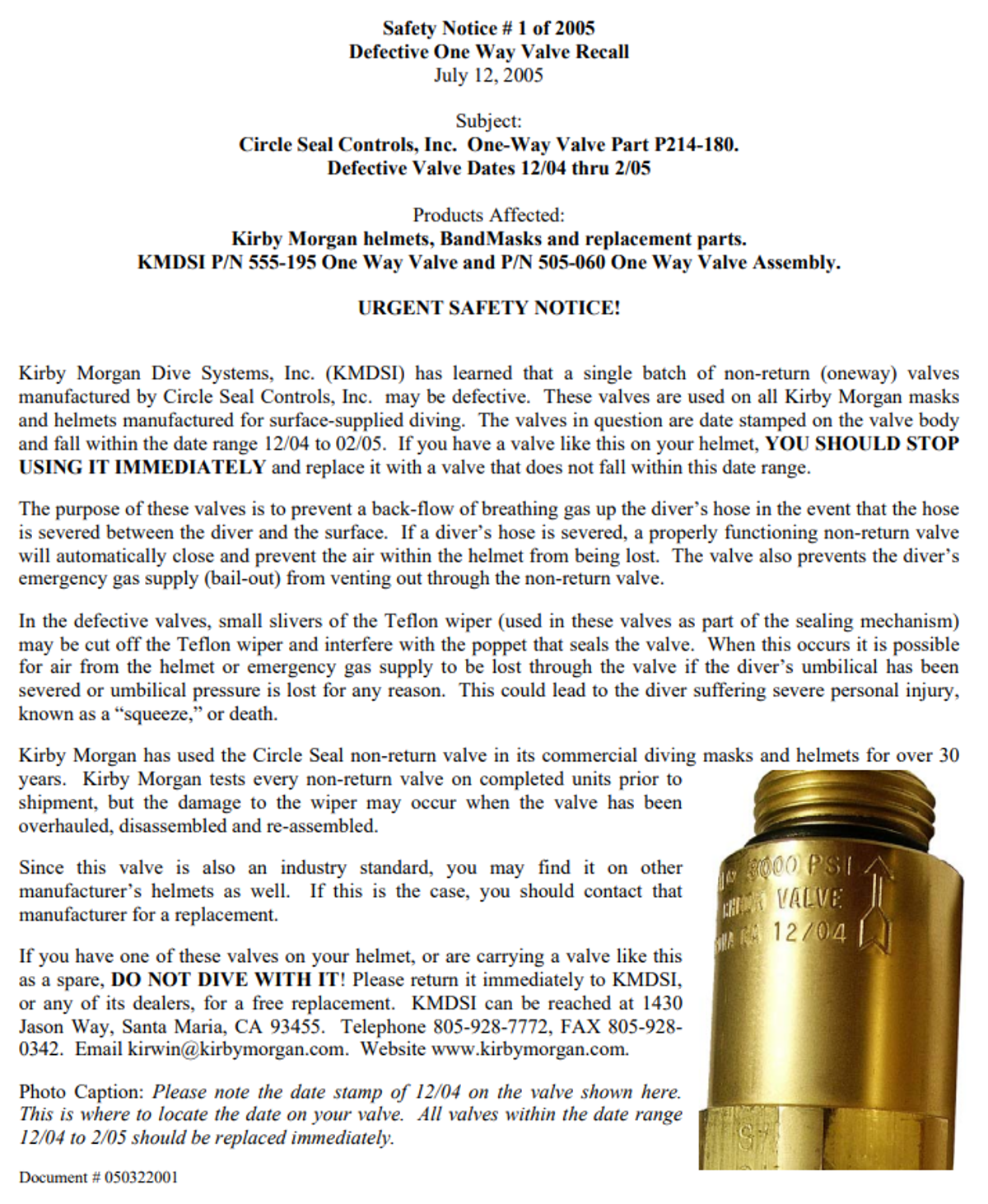

To date, defects have been encountered in the following batch numbers:

- P214-180 12/04

- P214-180 02/05

This may suggest potential of other batches which may exhibit similar faults.

The incidents to date have been as follows:

- Scenario 1 – It would appear that the random inability of the valve to seat was due to material peeling off the seal wiper (part #34). The material has been found to be bypassing the ‘o’-ring seal (part #33) and lodging in the seat. This has occurred each time the seat has been connected or disconnected from the body. This is not a single unit occurrence and appears to be prevalent in batch P214-180 12/04. Further investigations are ongoing.

- Scenario 2 – During further investigation of non-return valves on the worksite, it was found that batch number P214 180 02/05 failed during bell checks and was subsequently found to ‘stick’ whilst shaken.

The diving contractor has had extended conversations with its supplier, which has contacted Kirby Morgan Dive Systems International – the diving helmet manufacturer (although we understand the manufacture of the non-return valve is sub-contracted). Discussions are ongoing, but the diving contractor feels an interim alert should be issued to all IMCA members and industry, identifying the potential problem and obvious severe consequences should umbilical services fail.

Kirby Morgan has subsequently issued the attached notice, which it has asked IMCA to distribute as soon as possible.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.