LTI: Finger injury caused while working with oil drums

- Safety Flash

- Published on 6 March 2020

- Generated on 19 February 2026

- IMCA SF 09/20

- 2 minute read

Jump to:

A crew member suffered a fracture to the right-hand ring finger whilst arranging 200l oil drums

The injured person was moving drums from a container using a pallet truck, assisted by a colleague.

During this work, the injured person trapped a finger between the drums.

At the time of the incident, there was no pain and the injured person continued to work.

Once the operation was over, the injured person went to the medic to report the accident and took painkillers before resuming work.

After shift, the injured person removed their safety gloves and found discolouration (purple/black) of the ring finger and returned to the vessel hospital again.

The doctor advised to disembark the injured person for further medical examination ashore. It was discovered that there was a fracture of the distal phalange of the right-hand ring finger. The person was considered unfit to work for 15 days.

What went wrong?

- The incident was not reported to shore-based management (the DPA) in a timely and appropriate way.

- There were no appropriate procedures in place for this kind of work.

- The risk was seen as tolerable – crew took an incorrect and complacent attitude towards safety.

- No-one intervened to stop the job.

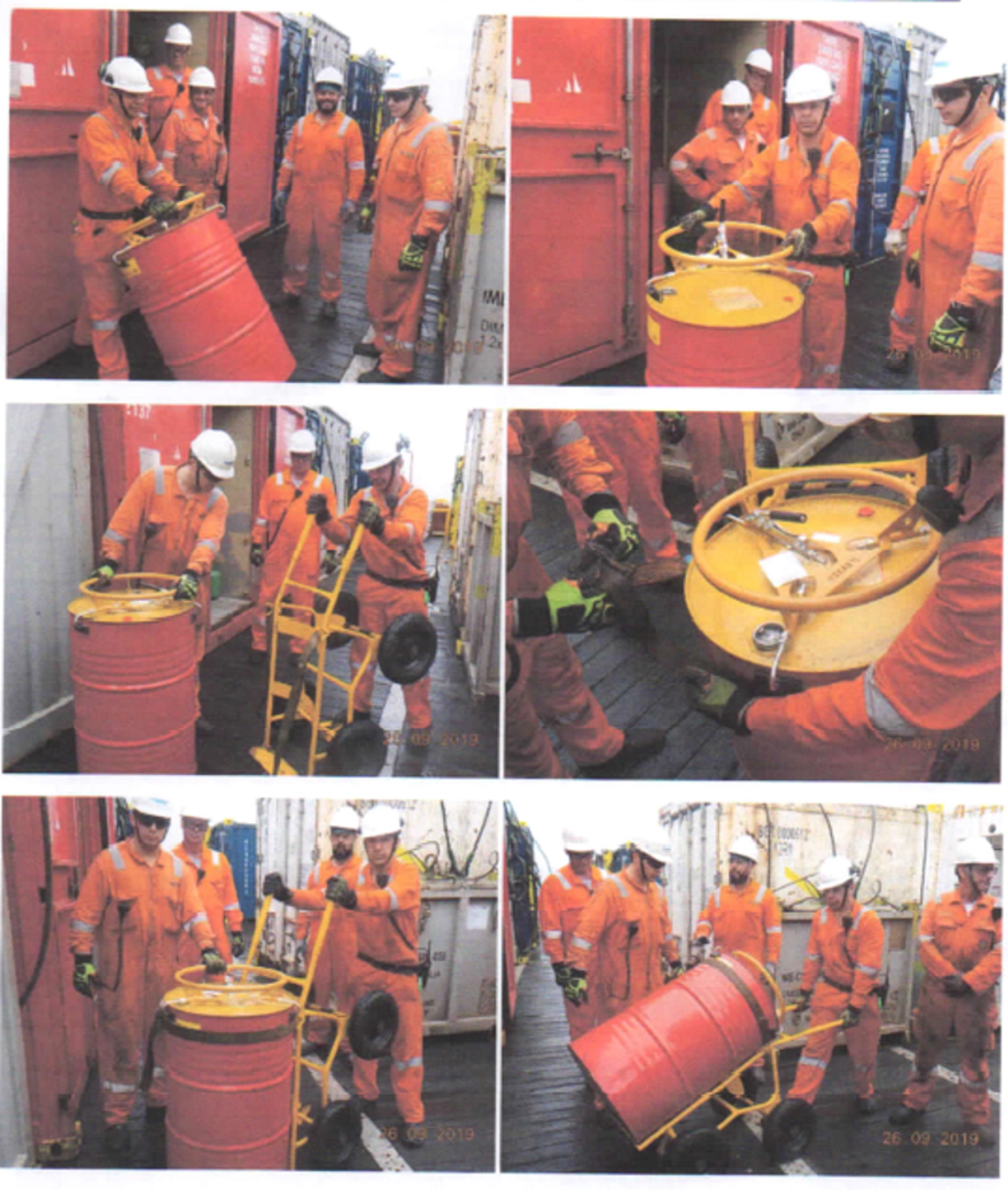

- There was no engineered mechanism to make this operation safer or hands-free. Such a mechanism was developed afterwards – see photos below.

What actions were taken?

- Suitable and sufficient risk assessment (RA) and toolbox talk (TBT) should be carried out for all routine and non-routine jobs, and these should make all crew involved aware of the dangers and risks involved with any particular job.

- Wherever manual handling is required, a proper handling method should be discussed and all hazards to be identified during RA/TBT and must be mitigated before starting work.

- Vessel management and crew to receive further instruction on hierarchy of safety controls.

- Engineered control – drum trolley and wheel – implemented on this vessel to remove people from the hazard.

Related Safety Flashes

-

IMCA SF 09/19

3 May 2019

-

-

IMCA SF 28/16

18 October 2016

-

IMCA SF 04/12

30 April 2012

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.