Near miss – lid on ash trash barrel blown off due to hot ash

- Safety Flash

- Published on 30 April 2024

- Generated on 3 July 2025

- IMCA SF 09/24

- 2 minute read

Jump to:

The lid on a waste container barrel blew off due to a build-up of excessive pressure within the waste container, caused by hot ash being deposited.

What happened?

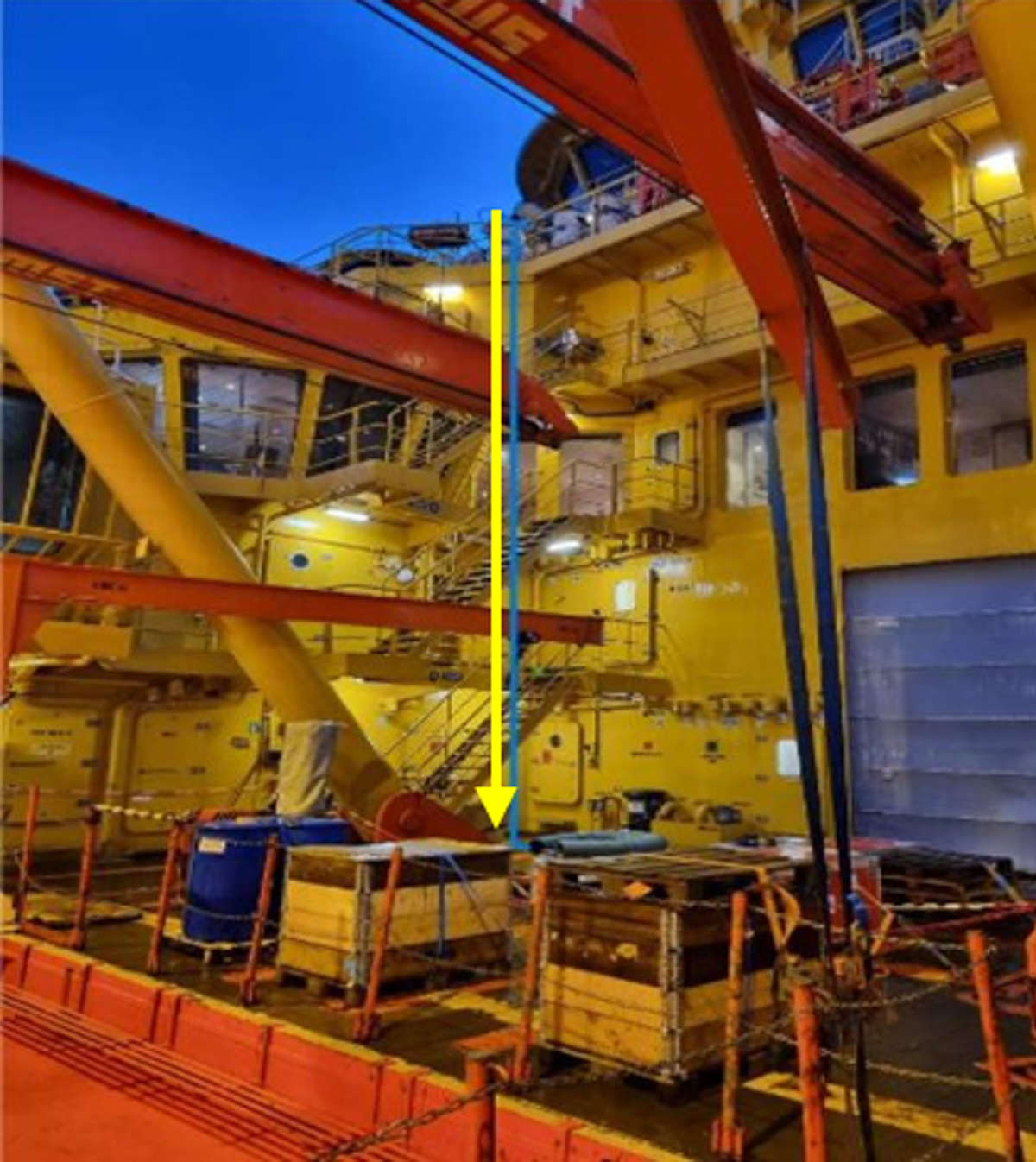

The build-up of pressure was observed by a member of the crew, who attempted to gradually open the compression ring on the waste container to allow for a slow and controlled release of pressure. The worker did not foresee the risk involved in this action; due to the pressure within the waste container the lid was forcefully dislodged from the locking clamp, releasing the lid from the waste container and causing it to fall 11m to the main deck below. No other personnel were present in the area during this incident.

What went wrong?

- Hot ash from the vessel incinerator was discharged into the waste container (used for offloading) and the waste container lid was closed immediately.

- Because the ashes of the incinerated waste were not yet cool, there was a build-up of hot gases. Pressure built up within the insufficiently ventilated container, causing it to inflate.

- When the crew member went to release the lid from the container, there was a loss of control and the lid was violently flung off.

What were the causes?

- There was insufficient assessment in general of the risks of dealing with incinerated waste and of its disposal.

- The risks of storing hot ash in an airtight container were not foreseen.

- Lack of knowledge – the risks of manually relieving the build-up of pressure were not understood.

Actions

- An improvement (a goose neck vent for waste containers) quickly identified and implemented.

- Updates in waste management procedure made, including risk assessment for handling and storage of hot ash.

Related Safety Flashes

-

IMCA SF 32/20

26 November 2020

-

-

IMCA SF 19/19

12 August 2019

-

-

IMCA SF 17/17

13 July 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.