Diver fatality: Underwater explosion

- Safety Flash

- Published on 2 August 2003

- Generated on 22 February 2026

- IMCA SF 10/03

- 2 minute read

Jump to:

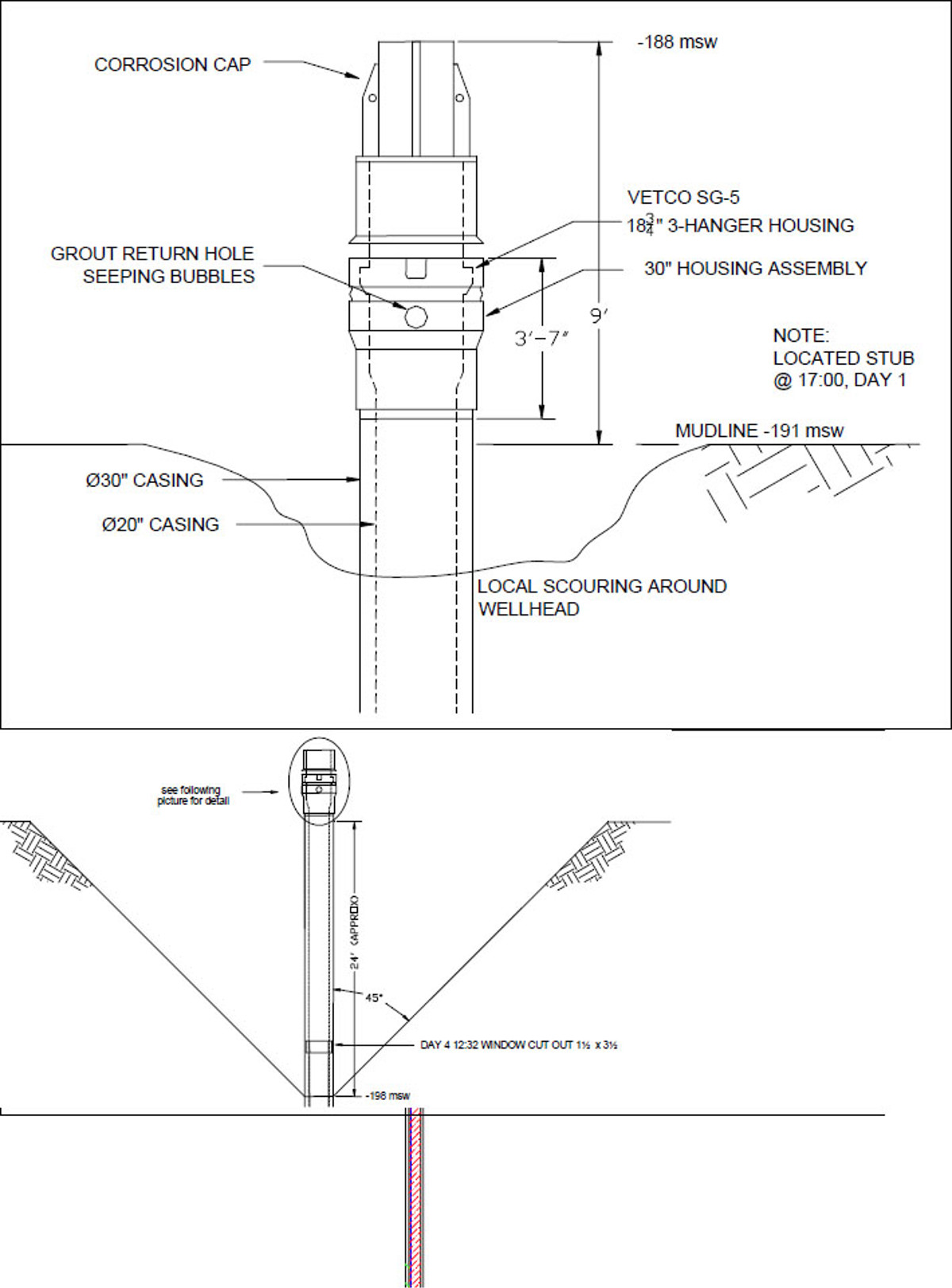

A Member has advised of a recent fatality, involving an experienced diver, which occurred during underwater cutting operations as part of a well stub removal project. The site conditions and sequence of events are summarised in the diagrams below.

The company’s subsequent investigation has noted the following findings:

- Site conditions had proved to be different from those represented in the end-customer’s drawing, in terms of the wellhead connector assembly, bubbling gas and lack of grout between annuli.

- Generic procedures had been produced for what had been considered a ‘standard’ or ‘routine’ well stub removal.

- The job safety analysis (JSA) had focused on excavation as the primary risk.

- A ‘can do/will do’ attitude can be prevalent among dive teams and in the wider industry, which may have caused some resistance to halt operations.

- The project manager only had limited involvement in this operation.

- The on-site procedure, developed by a widely experienced team of diving superintendent, supervisor and diver, proved to be not adequate to avoid the fatality.

The company has noted the following actions:

- It has instigated a ‘formal request for information’ procedure for retrieval of additional information from customers.

- It has reiterated that salvage and burning jobs are never ‘routine’ and are potentially hazardous. It has noted the need for detailed procedures and project risk assessments to be prepared, as per its project management procedures.

- It has noted the need for project management procedures to include formal job handover procedures and project risk assessments.

- It has pointed out the need for formal project risk assessments and work site job safety analyses (JSAs) to identify all potential risks before commencement of operations.

- It is aiming for a better implementation of its ‘safety stand-down’ system through reinforcement training, in accordance with its management-of-change procedures, to bring about a ‘can do/will do safely’ culture embraced by all employees.

- Again in relation to a better implementation of its management-of-change procedures, the company has noted that, whenever appropriate, project managers, senior and/or onshore management and the customer are to be involved in and to approve all significant changes to procedures.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.