SIMOPS – Smoke from hot work task enters confined space

- Safety Flash

- Published on 8 April 2021

- Generated on 9 February 2026

- IMCA SF 10/21

- 3 minute read

Jump to:

A portable fan providing fresh air to a tank cleaning operation (requiring confined space entry permit) began drawing in smoke from an oxy-propane cutting operation nearby; the workers inside the confined space were instructed to vacate the tank immediately; no-one was harmed

What happened?

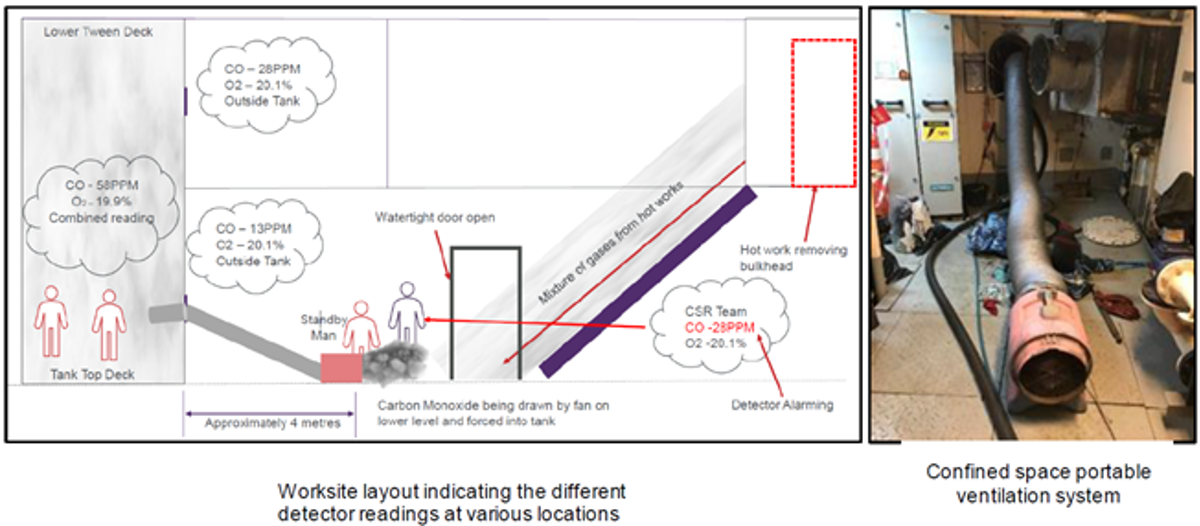

On a vessel in dry dock, confined space entry was required for the cleaning of the vessel sewage tanks. Nearby, shipyard workers were removing a section of bulkhead using oxy-propane cutting equipment. The smoke generated from this activity was being drawn down a stairway to the deck below by a portable ventilation fan. The fan had been set up to provide clean air for the sewage tank cleaning operation. The smoke was then sucked into the portable ventilation and forced into the confined space.

The two workers who entered the confined space were equipped with gas detectors capable of monitoring Oxygen, H2S and Methane as detailed in the risk assessment. Due to the nature of task, monitoring of Carbon Monoxide was not required.

A member of the confined space rescue team was performing a routine site inspection of the area and observed high levels of smoke. As he entered the hot work area his carbon monoxide low alarm activated on his gas detector. He also noticed the smoke being sucked into the portable ventilation system and immediately called an All Stop. The workers inside the confined space were instructed to immediately vacate the tank. No-one was harmed.

What went wrong?

- The sub-contracted tank cleaning work party were wearing their gas monitors inside their protective oversuits potentially preventing them from functioning correctly.

- The work party was also unaware of the requirement to perform daily “bump tests” on their gas detectors, and the calibration for all their detectors was out of date.

- The hot-work work party and the tank sentry did not recognise the smoke to be a hazardous condition and therefore did not intervene.

Lessons and actions

The following good practice was noted:

- The confined space rescue team recognised the unsafe condition and stopped the job.

The following immediate improvements were identified:

- Additional focus to be placed on SIMOPS during the daily planning meeting.

- Onsite checks of all sub-contractor equipment and worksite layout to be performed by confined space entry rescue team before work starts in a confined space.

- More effective fume extraction should be used during hot work activities.

- Ensure all tank sentries fully understand their role and responsibilities and the hazards associated with confined space entry.

- The sub-contracted cleaning company made the following changes:

- Correct calibration and bump testing of gas detectors as per manufacturer’s instructions.

- Required wearing of gas detectors outside of protective suits.

- Correct calibration and bump testing of gas detectors as per manufacturer’s instructions.

Members may wish to refer to

- IMCA M203 Guidance on simultaneous operations (SIMOPs)

Related Safety Flashes

-

IMCA SF 04/21

2 February 2021

-

-

IMCA SF 28/19

6 December 2019

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.