COBRA System – Hose coupling cross threaded

- Safety Flash

- Published on 21 April 2022

- Generated on 2 July 2025

- IMCA SF 10/22

- 2 minute read

Jump to:

During diving operations, diver 1’s right-hand COBRA hose had a “champagne” leak coming from the connection at the hat.

What happened?

The diver was instructed to return to the bell and the hose was changed. After the hose was changed, the diver lock-out checks were carried out and completed.

Once on the seabed, diver 2 was instructed to check diver 1’s COBRA hose for leaks; a small champagne leak was noted. Diver 2 was able to stop the leak by tightening the knurled collar on the COBRA hose.

At the end of the dive, diver 1 returned to the bell, the bellman inspected the divers’ hat and it was identified that the right-hand hose knurled retaining collar at the hat connection had been cross-threaded and not fully tightened. This resulted in the hose pulling free from the hat when the bellman lifted the hat clear of the divers head with the pulley system.

What went wrong?

Our member noted the following error precursors:

- In the work environment, there was a lack of alternative indication – no other indication that the coupling is fully engaged, other than visual and the Rotawink green indicator. There was poor access and equipment layout – the bellman has limited manoeuvrability within the bell when fitting the hose.

- With regard to human nature, there was an assumption that the Rotowink would remain red if the coupling was not properly engaged (cross threaded).

Lessons learned

- Bellman and dive supervisor followed the pre-lockout checklist correctly and verified that the Rotowink indicator was green.

- The Rotowink (shown here) is a visual indicator that turns green when the system is pressurised and ready for use. Although coupling was cross threaded, the Rotowink remained green throughout the dive indicating that the system retained a positive pressure.

- Ensure awareness is provided on:

- The potential for the coupling to be misaligned.

- The Rotowink may still give a green indication when coupling is misaligned.

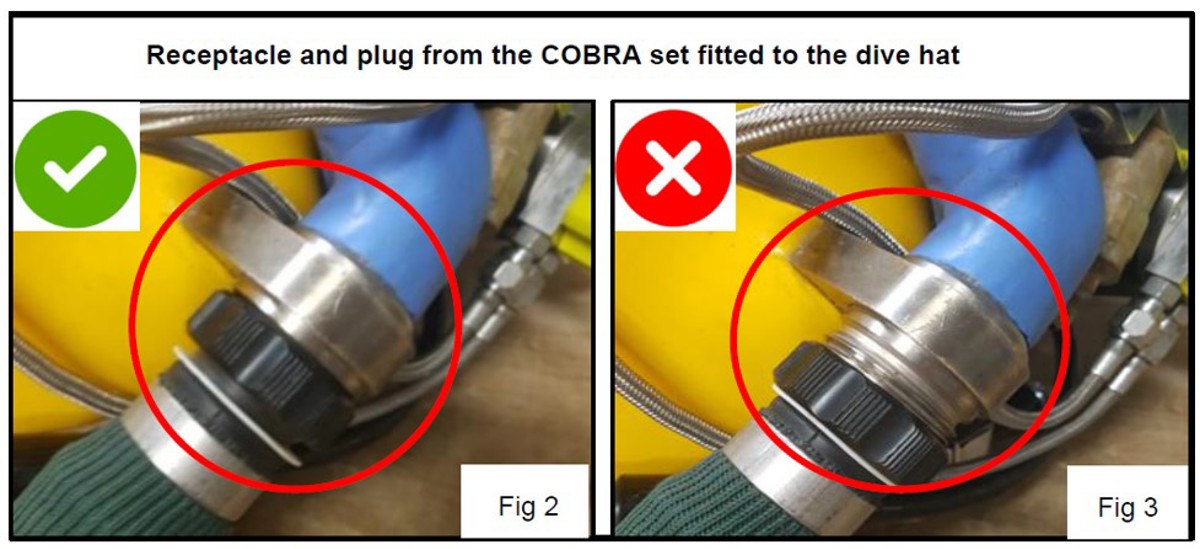

- When correctly connected there must be no visible threads, as per fig 2 above.

- Engaged with supplier to request a review of COBRA coupling mechanism to see if engineering solutions within existing pressure couplings can be used (i.e. HP gas spin fits).

Members may wish to refer to:

IMCA D018 Code of practice for the initial and periodic examination, testing and certification of diving plant and equipment

Related Safety Flashes

-

IMCA SF 21/21

30 July 2021

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.