Near miss – Messroom fridge fell over during rough seas

- Safety Flash

- Published on 20 April 2023

- Generated on 4 February 2026

- IMCA SF 10/23

- 2 minute read

Jump to:

During transit through heavy seas, a fridge tore loose from the messroom wall and fell on its side.

What happened?

The incident occurred when the vessel was transiting out to the field and was experiencing 3-4m seas.

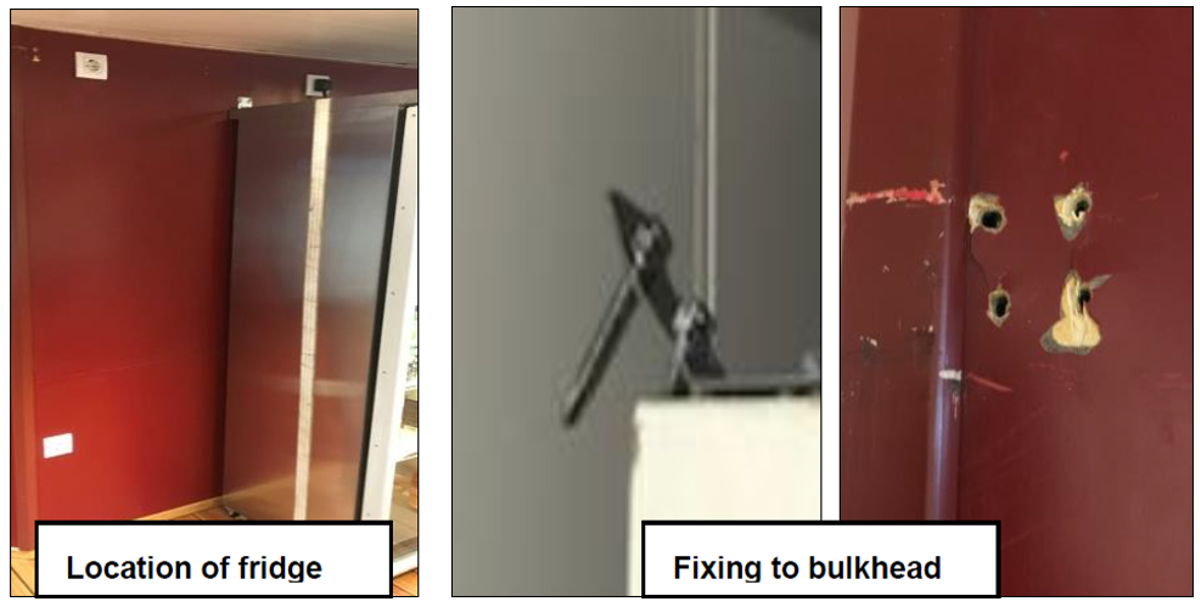

During one large roll, a tall fridge in the messroom came away from the bulkhead after its primary securing brackets were pulled out of the bulkhead due to the motion of the vessel.

The fridge swung on the last remaining fixing before falling on its side.

Although there were personnel in the messroom at the time there were no injuries reported and the potential for injury was unlikely. Minor damage was sustained to the fridge.

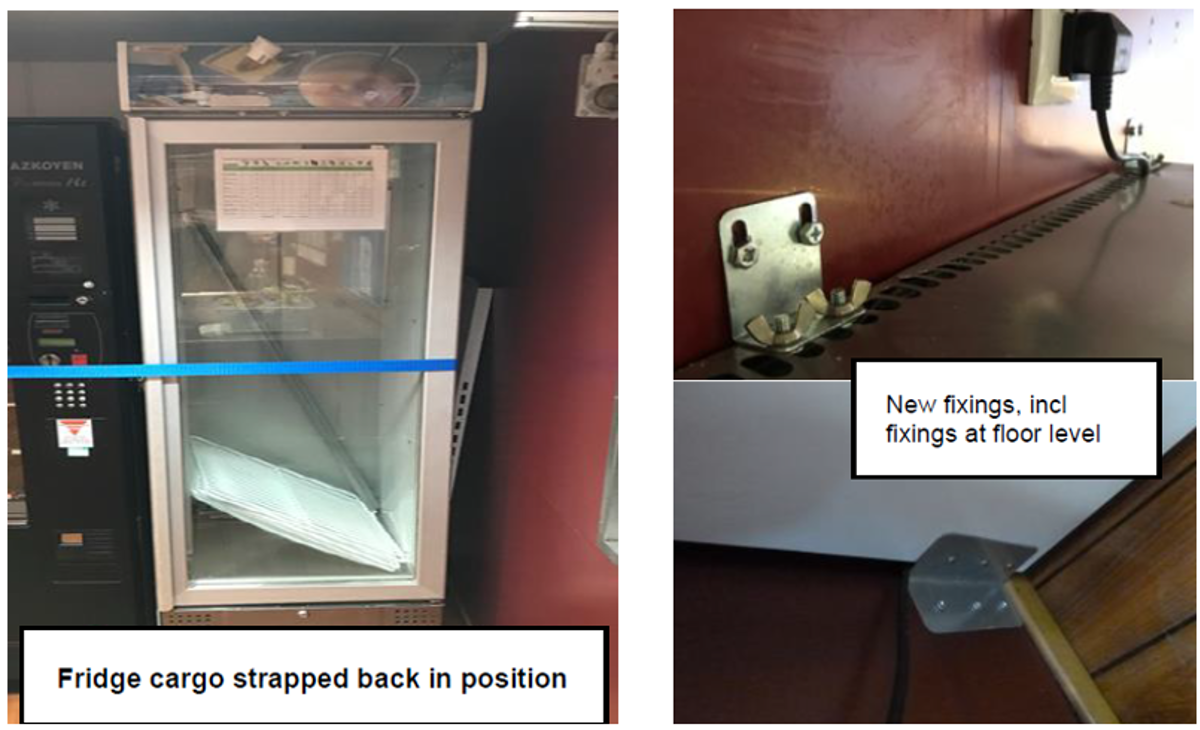

The fridge was secured to the deck with cargo straps and later returned to the upright position, inspected by the ships electrician and secured to the bulkhead with alternative suitable fixings.

What went wrong?

- Inadequate primary fixings used to secure fridge to bulkhead.

- The strength of the bulkhead construction (a stud wall) not taken into consideration.

- No-one took into consideration, the potential failure of fixings during rough seas.

Lessons learned

- Could this happen on your vessel?

- Identify and inspect heavy objects in the accommodation areas e.g. galley, gym, etc to ensure that the securing is robust enough to withstand rough seas.

- Identify and inspect heavy objects in the accommodation areas e.g. galley, gym, etc to ensure that the securing is robust enough to withstand rough seas.

- When securing items consideration should also be given to what these fixings are secured to, in this example the hollow stud wall was not considered when securing the fridge. The fixings are no stronger than what they fixed to!!

- Suitable fixings for hollow/cavity walls should be utilised for fixing equipment, e.g. hollow wall anchors.

Related safety flashes

-

IMCA SF 16/22

4 July 2022

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.