Grinding disc with defects

- Safety Flash

- Published on 27 October 2011

- Generated on 3 March 2026

- IMCA SF 11/11

- 1 minute read

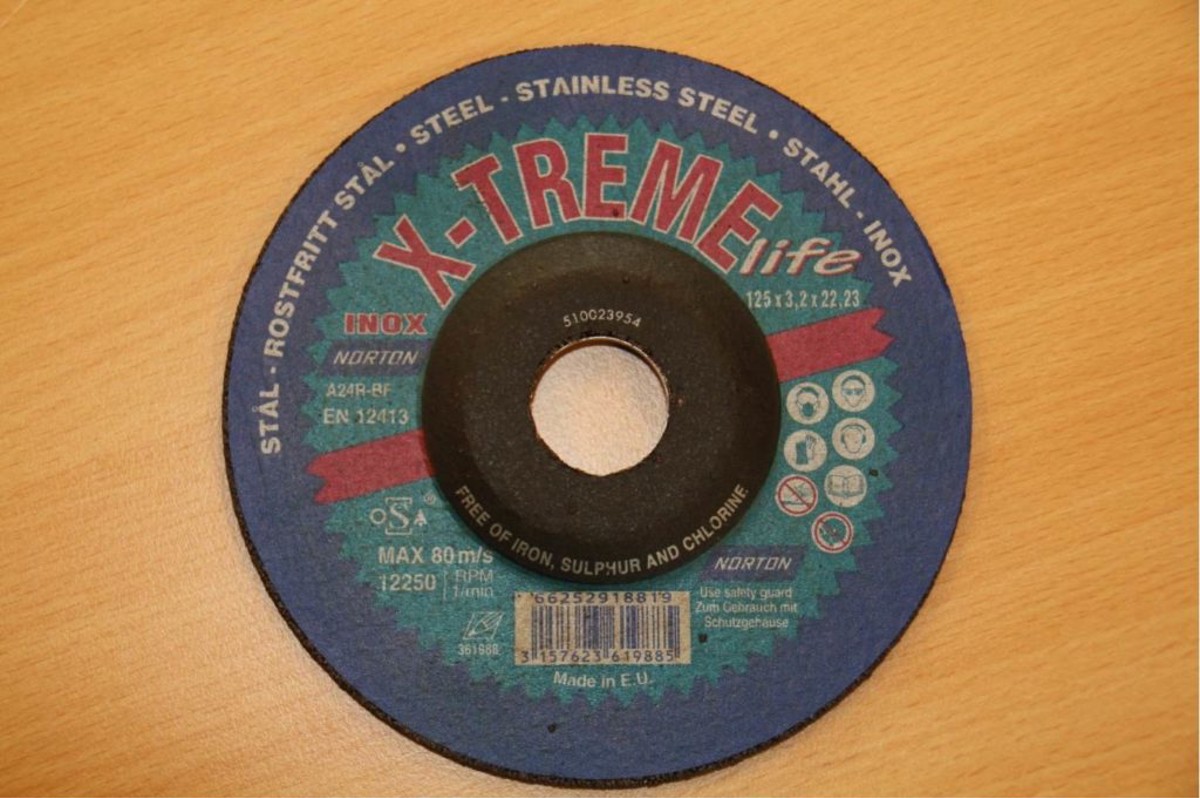

A Member has reported an incident in which a welder discovered a defect in a new grinding disc.

When grinding, the defect could have resulted in the disc cracking leading to possible serious injury or damage. The defect seemed to be a disc steel inner ring that had melted into the disc during fabrication.

It was noted that safe grinding starts and ends with a visual inspection of the grinding equipment. The welder followed recommended process and identified a defective disc before it was used.

iron ring melted into the disc

top side of grinding disc with no marks of defect

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.