Maintenance and control of fire doors

- Safety Flash

- Published on 3 May 2023

- Generated on 4 March 2026

- IMCA SF 11/23

- 2 minute read

Jump to:

A Member has discovered instances of mandatory fire doors onboard their vessels being in a poor state of maintenance, and in some cases modified to alter the closing mechanism or tied back to prevent closing.

What happened?

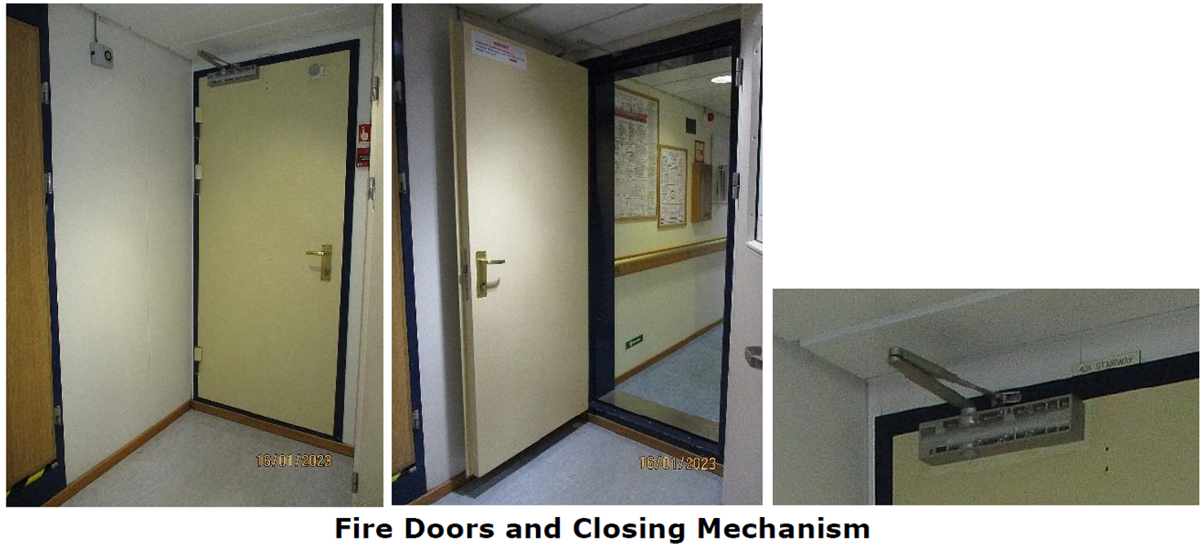

A member has discovered instances of mandatory fire doors onboard their vessels being in a poor state of maintenance, and in some cases modified to alter the closing mechanism or tied back to prevent closing.

Our member notes that in recent months there have been repeated internal and external audit findings related to inadequate maintenance, unapproved modification and the incorrect functioning of fire doors onboard their vessels.

This has included Port State Control Inspection deficiencies that have raised safety concerns and been communicated to the Flag State Authorities.

What was wrong?

Inadequate maintenance and unapproved modifications reduce the effectiveness of fire and smoke boundaries significantly, with potentially serious consequences during a fire and increased risk to crews and assets.

- Fire doors have been found to not close and seal properly.

- Fire doors have been modified to alter the speed of closure.

- Fire doors have been tied back to prevent closure.

Actions

- Ensure that no fire doors are modified or tied back to prevent closure or modify the speed of closure.

- Ensure all fire doors close automatically, by the self-closing mechanism and seal completely, including any hose ports.

- Ensure that routine maintenance and inspection regimes are followed.

- Ensure that where any defects are found, these are reported immediately.

Related safety flashes

-

IMCA SF 01/22

10 January 2022

-

-

IMCA SF 19/21

12 July 2021

-

-

IMCA SF 06/21

23 February 2021

-

-

IMCA SF 03/14

13 March 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.