Swinging load after loss of position

- Safety Flash

- Published on 18 June 2024

- Generated on 24 February 2026

- IMCA SF 12/24

- 2 minute read

Jump to:

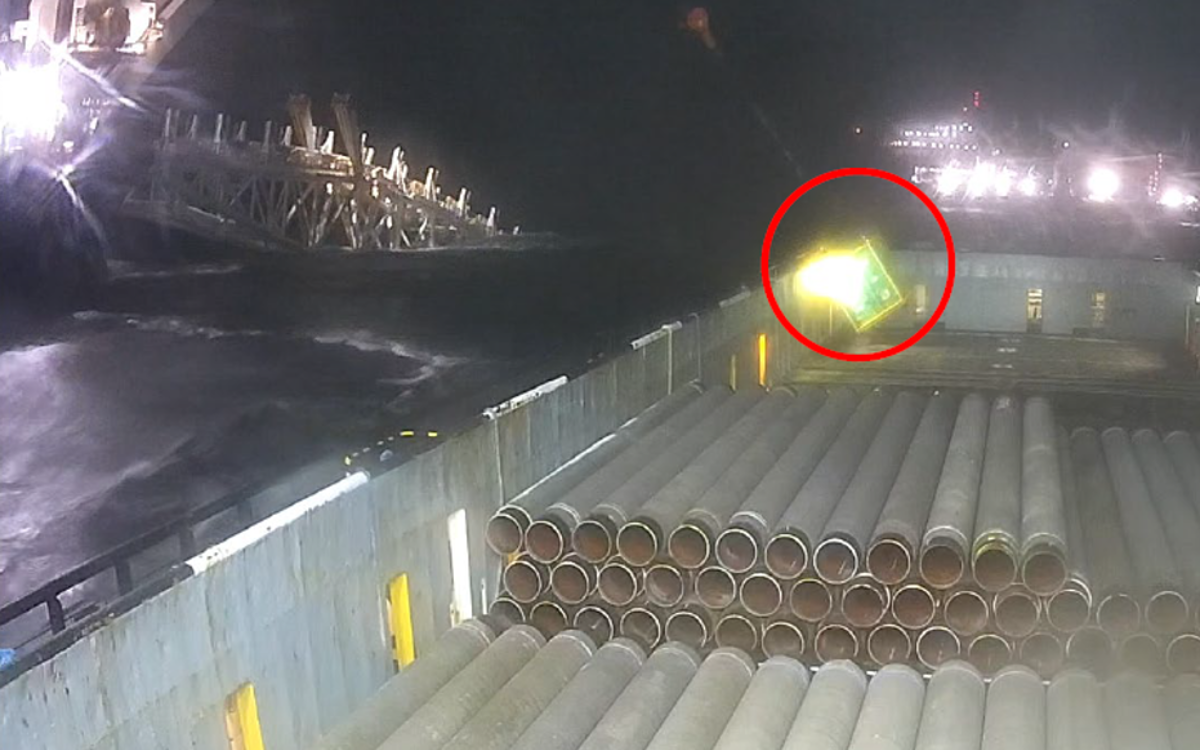

PSV suffered loss of position and an uncontrolled swinging load.

What happened?

During backloading of an empty refrigerated container to a Pipe Supply Vessel (PSV), adverse weather conditions, combined with technical issues and the effect of high thrust wash, resulted in a loss of position of the PSV and an uncontrolled swinging load. There was no damage to equipment and no-one was harmed.

This event will also appear as an IMCA DP Incident report.

What went wrong?

- Sudden gusts of wind of around 40 knots created high external forces, which resulted in an increased thruster wash towards the PSV, which caused the PSV to lose position.

- The PSV’s azimuth thruster lost its running DP signal, contributing to the loss of position.

- The PSV was operating outside its Activity Specific Operation Guidelines (ASOG).

- The operational limits of PSVs operating alongside were not considered in the Activity Specific Operation Guidelines (ASOG).

- No-one stopped the job: the operation wasn’t stopped despite alarms indicating the PSV was outside defined operational limits.

Lessons learned

- Review any (project specific) ASOG to include vessel to vessel operations and the effect that thruster wash can have on vessels alongside.

- Review and update procedures for the lifting of cargo to/from PSVs to reflect the potential for loss of position.

- Ensure personnel responsible for DP operations review and consider the requirements of the ASOGs and document their review process.

- Planning, risk assessing and adhering to operational guidelines and limits is crucial to ensuring safe cargo transfer operations.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.