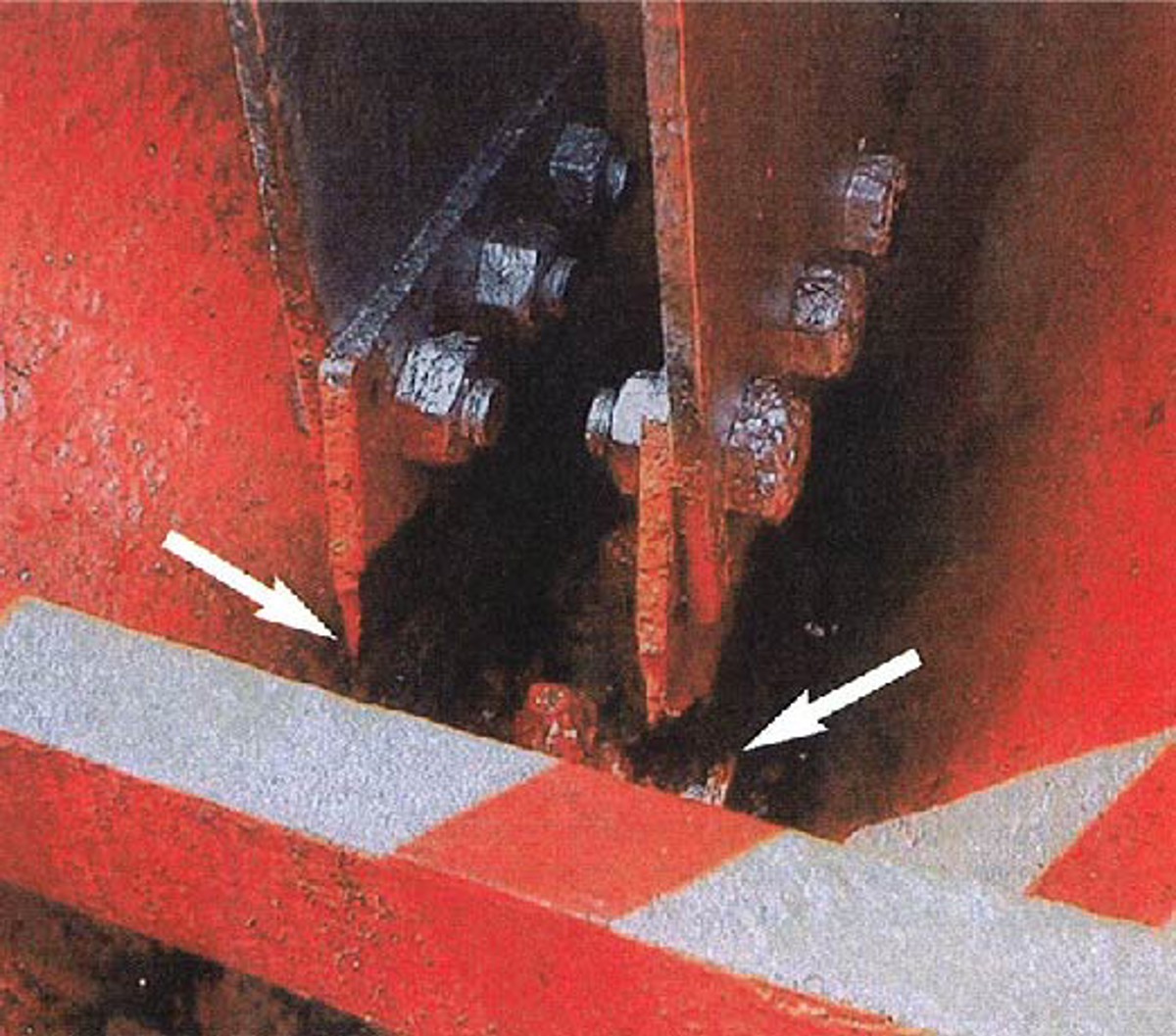

Open lifeboat – corroded tie band side plates

- Safety Flash

- Published on 21 November 2006

- Generated on 3 July 2025

- IMCA SF 13/06

- 2 minute read

Jump to:

IMCA has received the following report regarding corrosion to lifeboat parts which could have resulted in loss of life.

What happened?

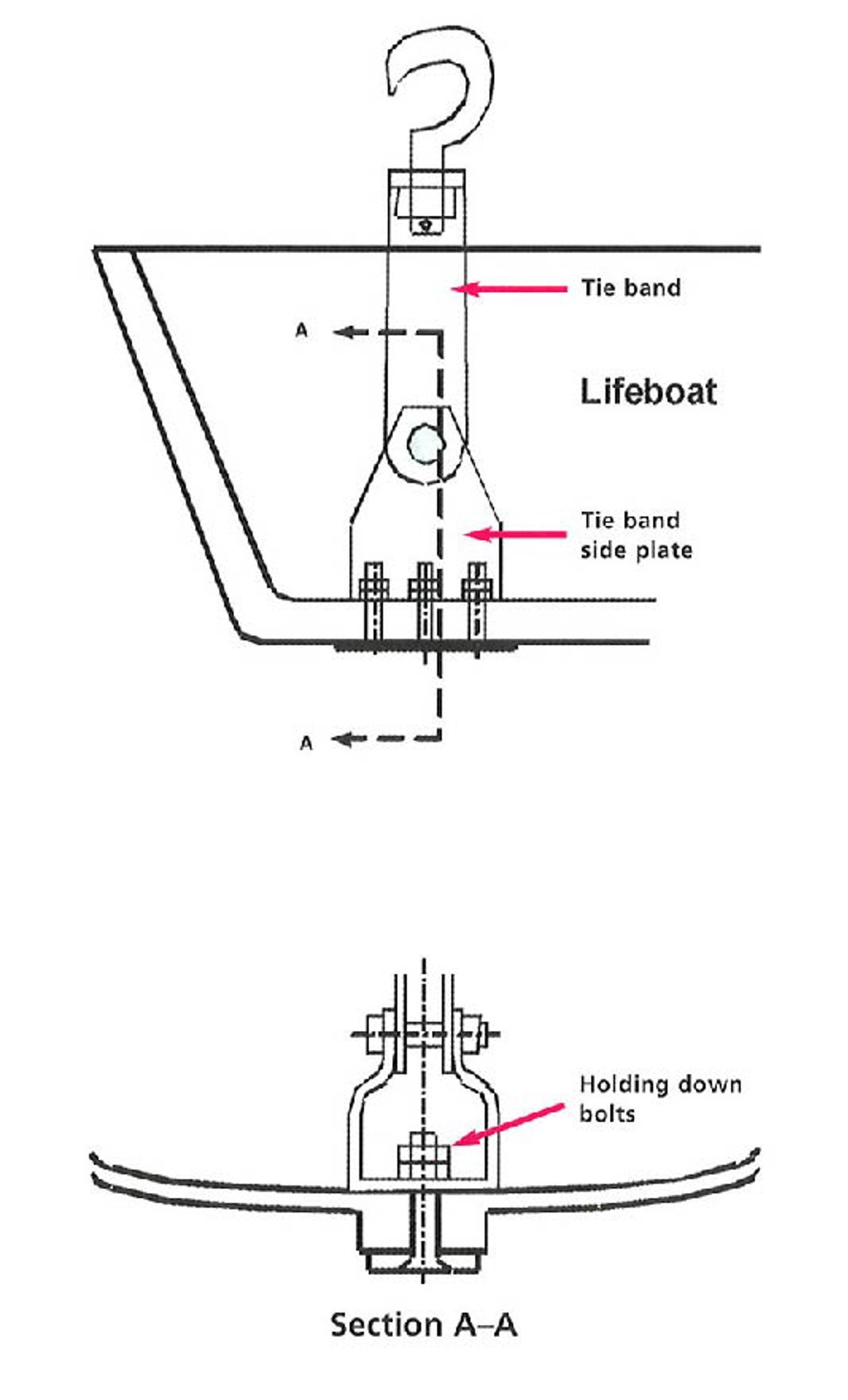

An empty open lifeboat was lowered to the embarkation platform, when the aft boat hook tie band gave way from its attachment to the keel of the lifeboat. Tie bands are vital structural elements for the safe and controlled launching of lifeboats. Fortunately there were no persons in the lifeboat. No-one was injured, but there was some mechanical damage.

It is believed that the corrosive environment at the bottom of the lifeboat, combined with lack of maintenance over time, led to extensive corrosion of the tie bands. Access to them can be difficult, hampered by the presence of debris and bilge water.

Further tests were made of other similar lifeboats, and the tie bands on these lifeboats were also found to be heavily corroded. Though well painted and appearing to be well preserved, it was clear that these were in poor shape.

Serious corrosion of tie band side plates at connection at bottom of lifeboat

Lessons learnt from this incident include:

- Lifeboat tie bands, hooks and release systems should be inspected and maintained according to the manufacturer’s recommendations, and be included in the vessel maintenance schedule.

- All items encompassed by scheduled inspections should be properly examined on a regular basis.

- Access to, and cleaning of, the tie bands side plates should be made prior to inspection of lifeboats.

- Special attention should be paid to the cleanliness of lifeboat bilges.

- Corrosion damage of this sort may also occur on totally enclosed or partially enclosed lifeboats.

DNV, which originally issued this alert, has pointed out the following:

SOLAS does not require people to be onboard when the boat is lowered during drills. In order to reduce the probability of casualties during drills, the following alternate procedures may be applied:

- Lifeboat first lowered to about 2 m above water then hoisted for boarding by assigned operating crew and lowered to water for release and manoeuvring.

- Alternatively, lifeboat to be lowered to the water without crew on board. Crew to embark via embarkation ladder, boat to be hoisted approximately 2-3 m and lowered again, controlled from inside lifeboat.

Tie band side plates connected to the lifeboat with three bolts and with one counter-nut per bolt

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.