Life jacket failures

- Safety Flash

- Published on 16 May 2016

- Generated on 3 July 2025

- IMCA SF 13/16

- 1 minute read

Jump to:

IMCA’s attention has been drawn to a number of cases of life jacket failure.

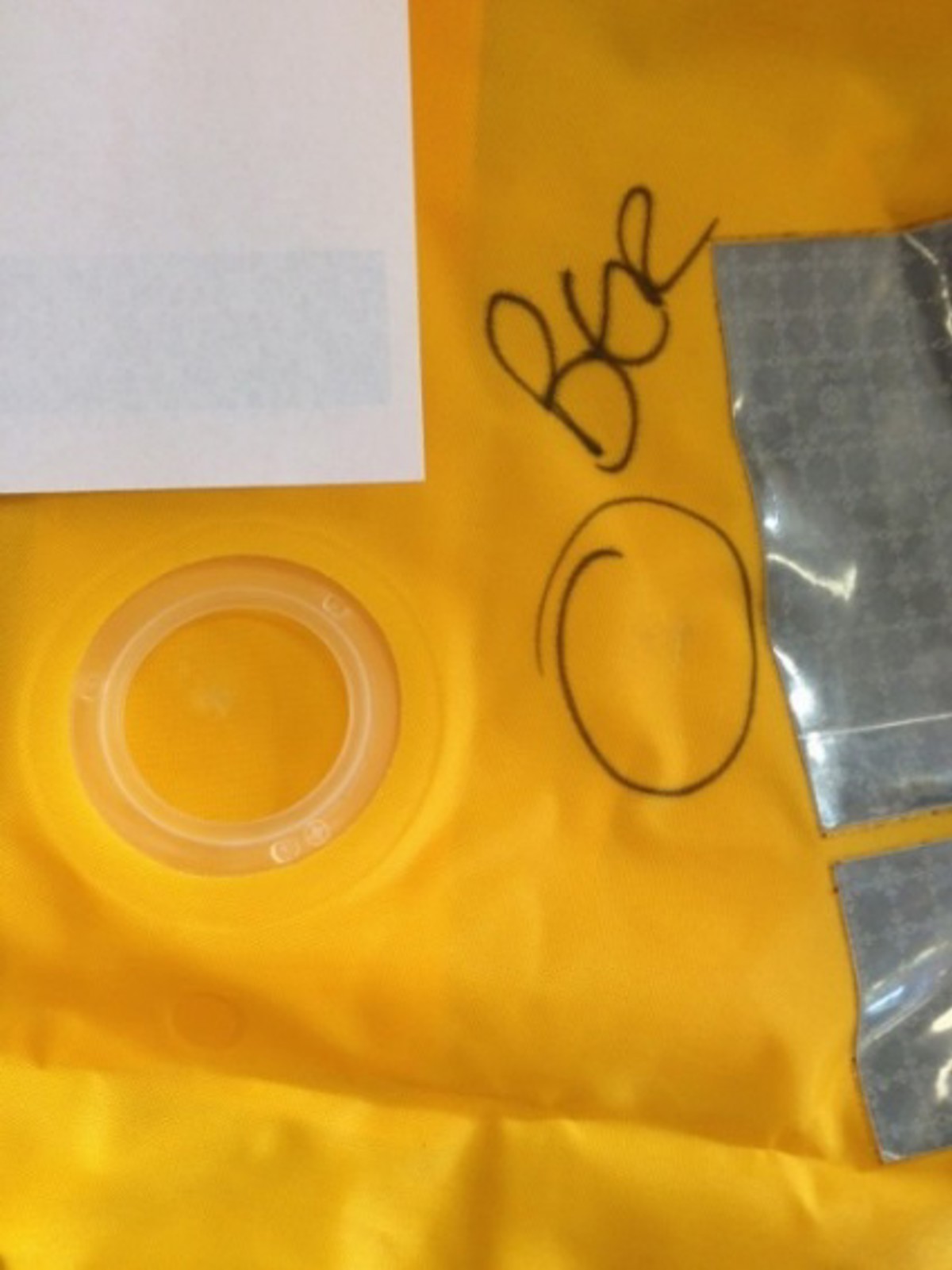

In recent months a contractor found that at least seven life jackets had failed for the same reason. Some of these jackets failed on their first annual test and inspection. The failure was due to a hole in the bladder and the hole is in the same place in each case.

The manufacturer informed their buyer that the damage was due to pressure applied to the front of the jacket when in use. This was causing the folded bladder to press up against the ‘Hammar’ automatic inflation device within the jacket, which in turn was causing damage to the bladder. The manufacturer is now fitting rubber covers to the automatic inflation device.

The following recommendations were made:

Members are encouraged to carry out a spot check and close examination of all life jackets fitted with automatic inflation devices and assess if any damage is occurring.

Consideration may be given to returning the jackets to a service station and requesting the rubber cap be fitted in addition to a service which includes an inflation test.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.