Lost time injury (LTI): fractured elbow – fall injury

- Safety Flash

- Published on 22 June 2018

- Generated on 2 July 2025

- IMCA SF 13/18

- 3 minute read

Jump to:

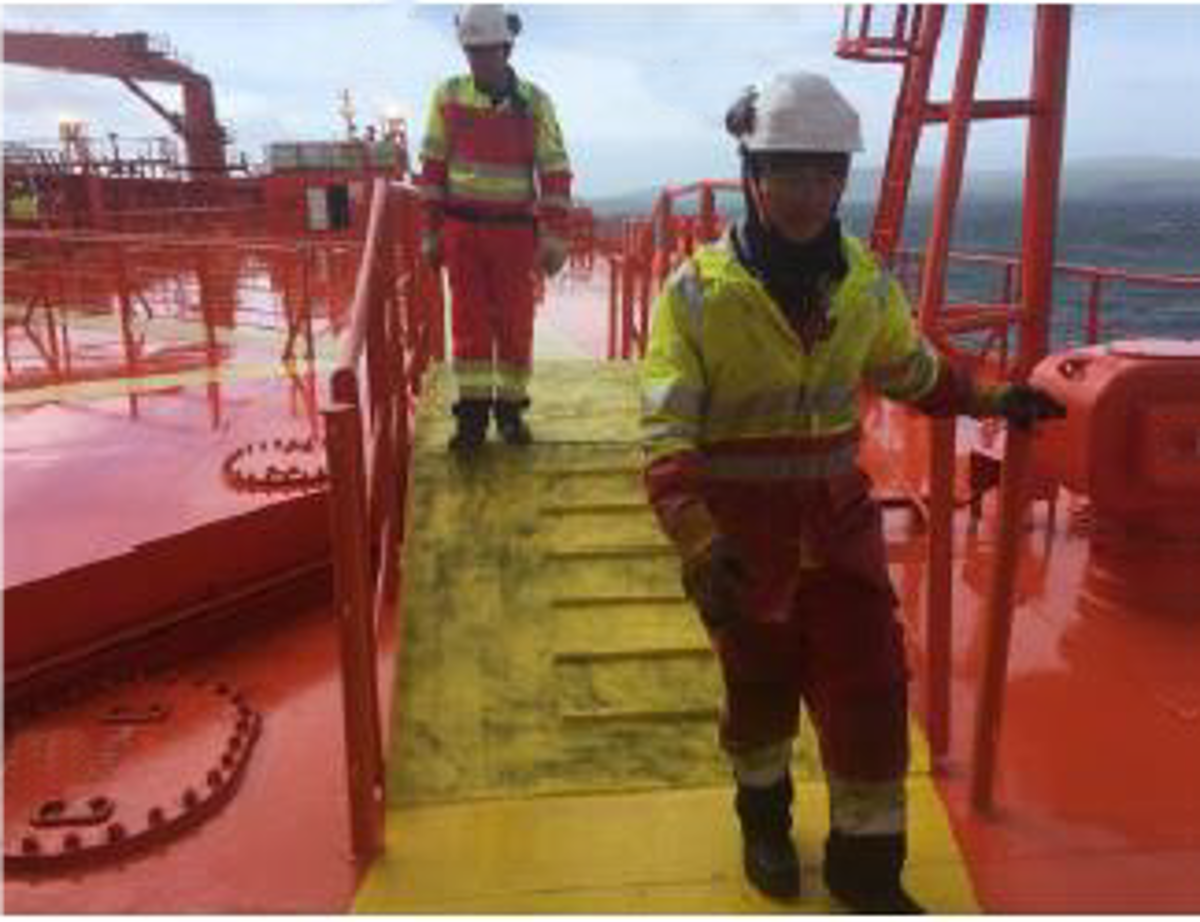

The Chief Officer slipped on a smooth section of ramping deck, landing badly and suffering a fractured elbow.

What happened?

The incident took place at crew change, when the Captain, Chief Officer and Engine Cadet joined the vessel. The Chief Officer and Captain walked along the yellow painted walkway to get into the accommodation. It had rained all morning, so the main deck was wet. The Captain walked over the anti-slip bars in the middle of the ramp, while the Chief Officer stepped onto the ramp and did not hold onto the railings on the side of the ramp. The Chief Officer continued walking on the smooth section of the ramp and slipped, heavily falling backwards and landing on his left elbow and buttocks.

Several days later, bruising was apparent around the Chief Officer’s left elbow, so he was sent to the hospital for medical examination. An X-ray revealed that he had fractured his elbow and he was sent home for full recovery.

What went wrong?

- Direct cause: improper stepping and handling – the injured person was not holding to the railings. Additionally, he ignored the use of the anti-slip bars that were welded onto the sloping ramp to prevent slips.

- Root cause: personal factors, Inadequate identification and evaluation of hazard or risks – the Chief Officer chose to ignore a safer option of stepping onto the non-slip bars and walked on a slippery deck. He was over-confident and underestimated the risk, leading to a familiarity bias and perceived control.

What actions were taken? What lessons were learned?

Our member used this incident for a timely review of similar slips/trips incidents within their fleet, and identified some personal factors or behavioural-based safety issues:

- “It’s alright, we normally doing this” – control bias – there will be jobs that are easy to do or easy to understand and can often be regarded as routine. We feel that we are in control and tend to neglect the risk that is actually present. We should keep in mind that even if a job has been done a number of times, there will generally always be some changes, which sometimes may not be obvious or noticeable. We should be more aware of these changes, even if they are deemed to be small.

- “The area is safe; it is newly painted with anti-skid coating.” – expectation bias – in this instance, the crew tend to overlook the situation and other hazards that lead to an unsafe act/condition. For example: wet surface, ship movement or not holding the railings.

- “We still have a lot of things to do, this job needs be completed ASAP.” – efficiency bias – due to time pressure, crews work in haste and tend to take shortcuts. Always remember, putting your safety first is always more important than completing the job speedily.

- “It has always been like this and nothing has ever happened.” – familiarity bias – crew are familiar with the situation onboard as well as its condition, since he/she has been onboard for some time.

Members may wish to view the IMCA short safety video on Preventing slips and trips.

Related Safety Flashes

-

IMCA SF 10/18

9 May 2018

-

-

IMCA SF 17/14

31 October 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.