Stored energy: injury caused by failure of expansion joint in fire-fighting equipment

- Safety Flash

- Published on 9 July 2018

- Generated on 22 February 2026

- IMCA SF 14/18

- 2 minute read

Jump to:

During a trial of fire-fighting equipment, a hose expansion joint or bellows failed.

What happened?

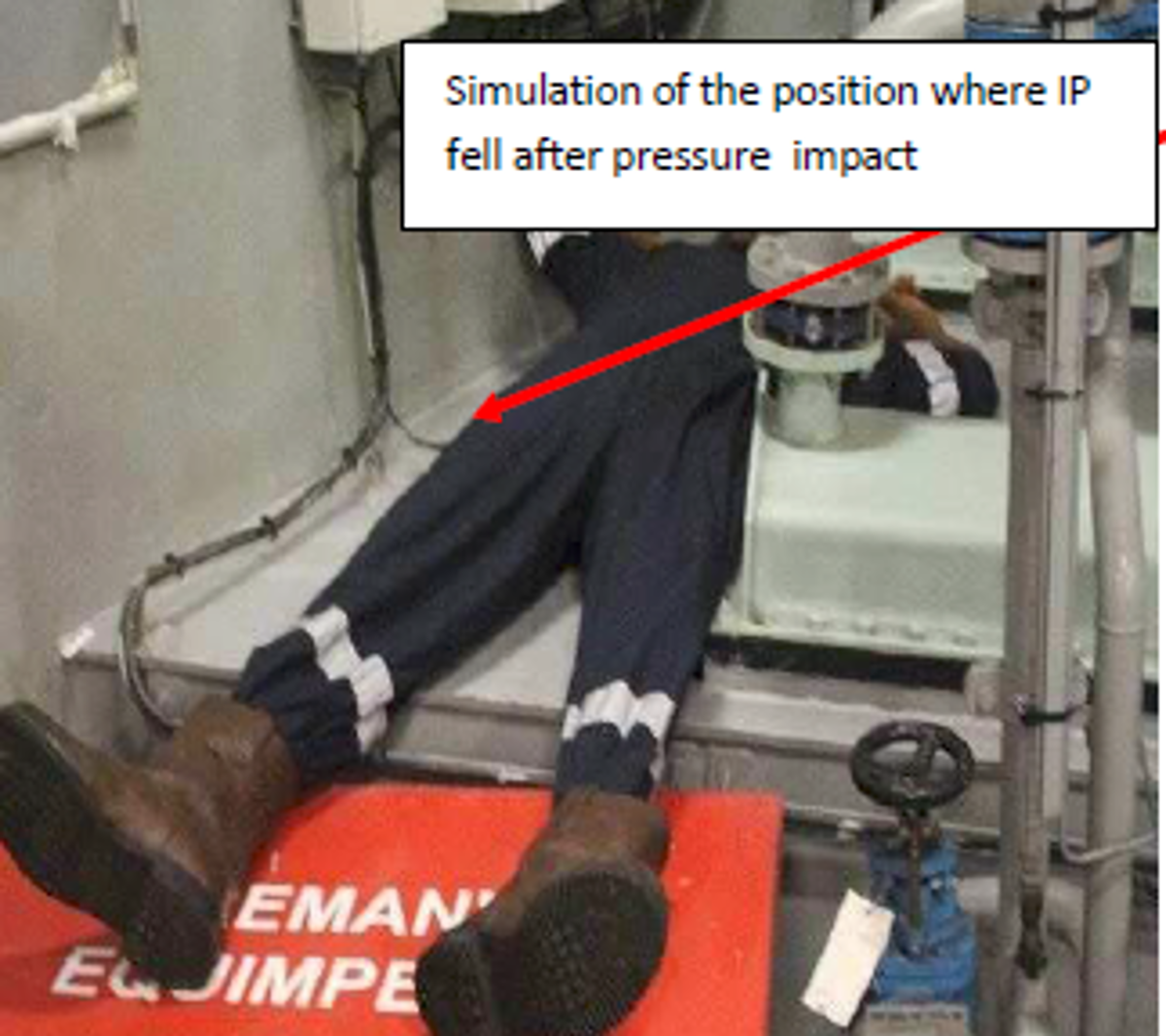

The release of pressurized water hit a crewman who was standing nearby, slamming him backward and knocking him unconscious. The fire pump was shut down and help was sought. CPR was administered; subsequently the injured person was medevaced.

This incident was considered by our member to be a potential fatality. The injured person was in hospital for some weeks.

What went wrong? What were the causes?

Some identified issues were:

- There was inadequate management of significant risk.

- There was no understanding of the life time of the expansion joint or bellows.

- There was no installation procedure provided for this bellows by the manufacturer.

- There was no preventive maintenance or inspection/testing of the failed equipment.

What actions were taken? What lessons were learned?

Our member drew the following lessons:

- There had been a similar rupture of a bellows some years previously; this earlier incident was not investigated. Had it been investigated, it might have helped in preventing reoccurrence.

- Engineering and design of critical equipment during new building should take into consideration personnel safety as well as equipment protection.

- There needs to be a better design review of pressurised equipment, particularly where different components are in use.

Related Safety Flashes

-

IMCA SF 16/14

3 October 2014

-

IMCA SF 10/07

20 December 2007

-

IMCA SF 09/03

1 August 2003

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.