MAIB: A heavy sheave fell over causing an LTI

- Safety Flash

- Published on 12 June 2023

- Generated on 7 March 2026

- IMCA SF 14/23

- 2 minute read

Jump to:

A bosun suffered a broken leg when a heavy sheave he was trying to manoeuvre, fell against him

What happened?

On a vessel going into port, crew were preparing to offload equipment.

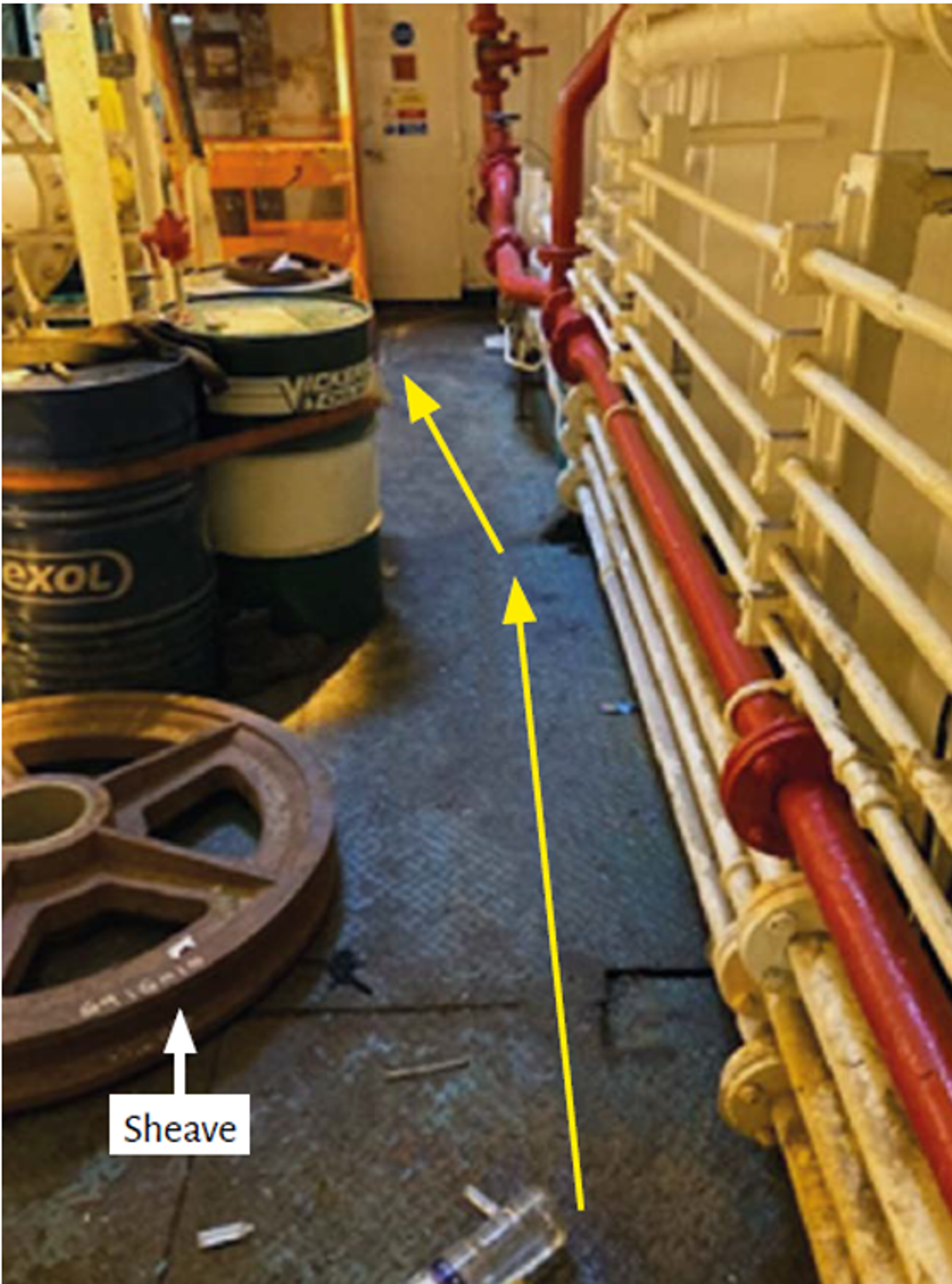

Very early in the morning, the bosun decided to prepare a 0.5t sheave, which was due to be lifted ashore. He removed the lashings that were securing the sheave vertically against some pipework and started to roll it toward the port side hatch in readiness for offload.

The bosun was manoeuvring the sheave past some oil drums when he lost control and the sheave toppled over, struck his thigh and then trapped him under its weight. With difficulty he managed to raise the alarm using his handheld radio.

The crew mustered quickly, lifted the sheave off his leg and administered first aid.

Once in port the bosun was taken to hospital with multiple fractures to his leg and was unable to return to work for several months.

What went wrong?

- The bosun worked alone.

- The sheave, half a ton and over 1m in diameter was not stowed in an authorised location.

- The crew had no lifting plan in place to move it across the space. The sheave was unwieldy and careful planning and thought would have been required before it could be moved safely, despite it being easy to roll.

- The bosun was unaware of the weight of the sheave and had underestimated the risks and hazards involved in both its removal and relocation.

Actions

- Don’t just “crack on” with a task rather than bother other people to get help – STOP and THINK.

- Have a clear, communicated and fully understood plan for moving an object of this size and weight.

Related safety flashes

-

IMCA SF 27/20

15 September 2020

-

-

IMCA SF 08/21

17 March 2021

-

-

IMCA SF 12/21

27 April 2021

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.