Importance of inspecting fall protection equipment

- Safety Flash

- Published on 23 October 2009

- Generated on 20 February 2026

- IMCA SF 15/09

- 1 minute read

IMCA has been made aware of a number of examples of fall protection equipment failing owing to poor or sub-standard equipment.

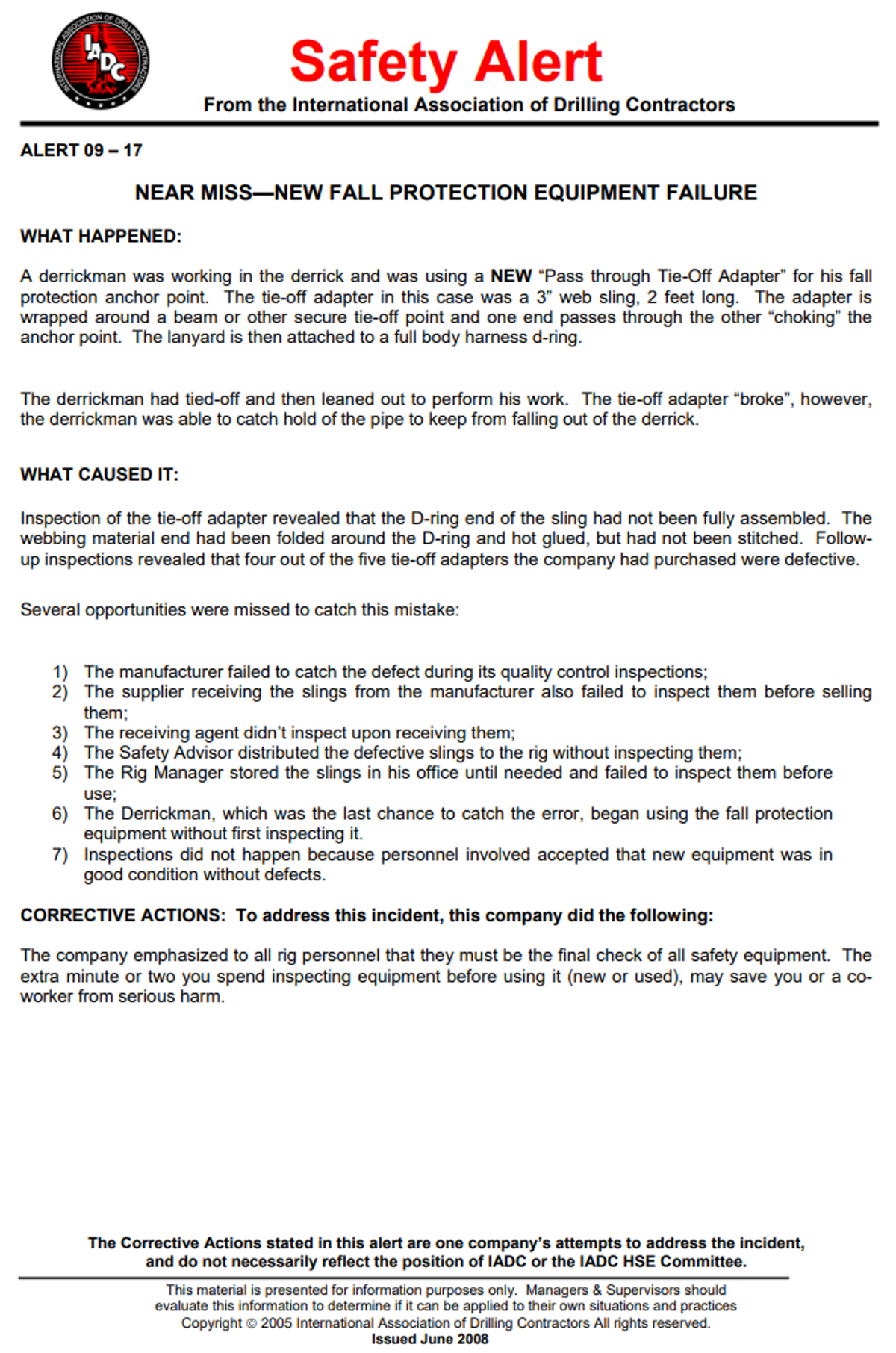

- Safety Alert 09-17 – Near Miss – New Fall Protection Equipment Failure, published by the International Association of Drilling Contractors (IADC) (see below), notes that a new ‘pass-through tie-off adapter’ was only hot-glued and did not have the required stitching.

- Whilst teaching a fall protection class, an instructor found a new piece of fall protection equipment that was not properly sewn. This equipment was brand new, still in the bag and made by a reliable manufacturer. One of the lanyards was improperly sewn and the webbing could be pulled apart by hand.

- In another similar instance, it was discovered that the rivet from the secondary lock on the snap hook of a lanyard had become damaged and allowed the secondary lock to come free from the hook. The hook was not involved in a fall event.

Members are encouraged to re-emphasise to their personnel the importance of thorough inspection of all fall protection equipment before and after use.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.