LTI: diver injured during water jetting operations

- Safety Flash

- Published on 20 July 2018

- Generated on 4 July 2025

- IMCA SF 15/18

- 2 minute read

Jump to:

A saturation diver suffered a lost time injury (LTI) to his left arm during subsea high-pressure water jetting operations.

What happened?

The incident occurred when the water jet gun failed, and a part came off the gun. The diver was recovered to the bell and the water jet gun to the surface. The diver received first aid in the bell and further treatment later in the chamber. He was subsequently decompressed and transferred to hospital. Though an LTI, the injury was not severe, and it was expected that the diver would return to his duties within months.

What went wrong? What were the causes?

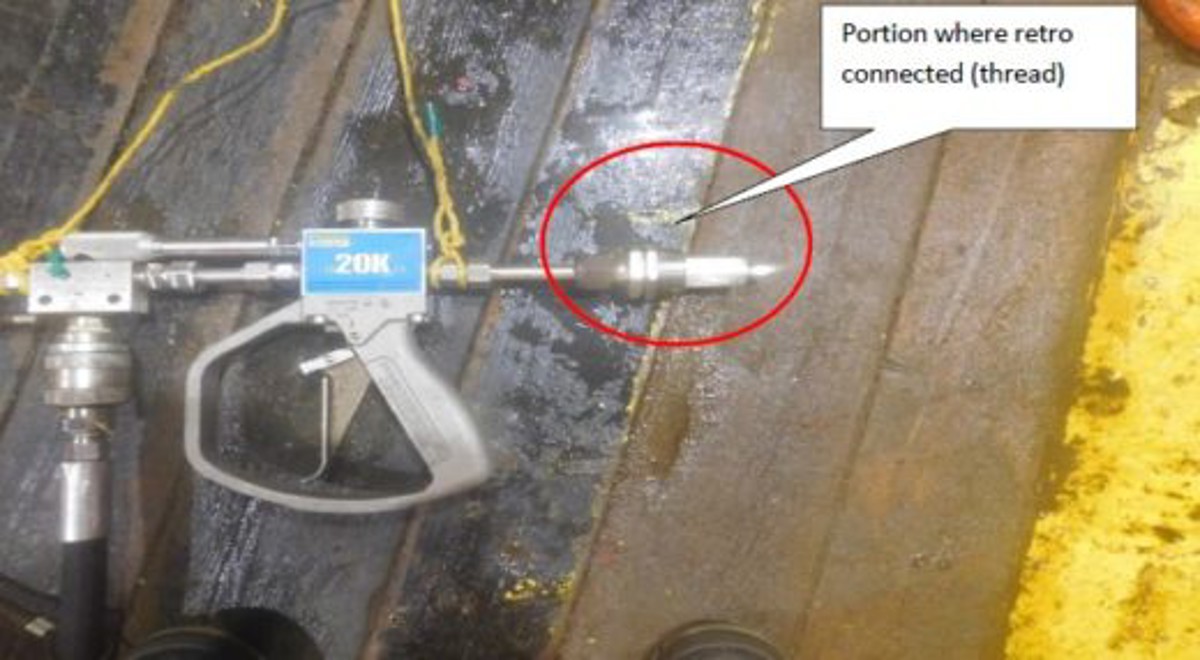

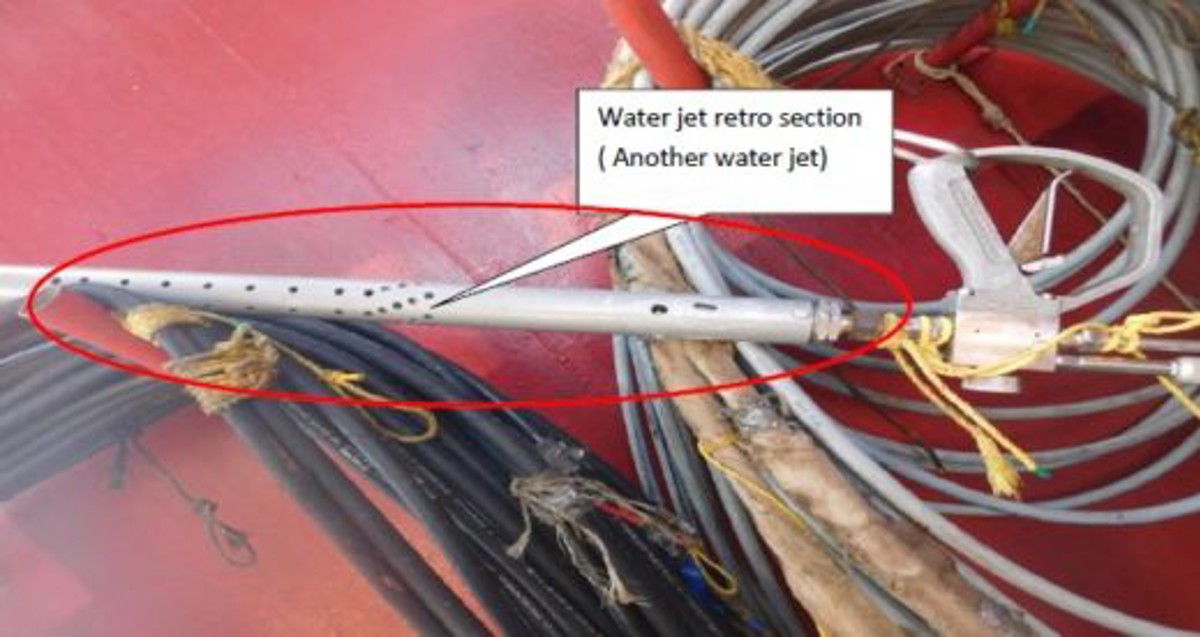

- Equipment failure: locking bolts on the water jet retro came loose.

- Unsafe design or construction: locking nuts did not have a holding mechanism besides the threads available.

- Improper worker training/familiarization: manufacturer manuals provided were not available at worksite. There was no awareness of the need for a planned maintenance system (PMS) for high pressure equipment of this sort.

- Improper maintenance: it was observed during investigation that maintenance was not carried out in accordance to manufacturer’s recommendations.

What actions were taken? What lessons were learned?

- Management of change (MoC) prepared for required changes.

- Ensure equipment is maintained in accordance with Code of practice for the use of high pressure jetting equipment by divers (IMCA D 049) and any manufacturer’s recommendations.

- Additional controls put in place to ensure the water jetting equipment is in safe condition, including checking condition of diffuser and locking nuts.

- Further awareness briefing given to dive team regarding checks of the equipment as per the manufacturer’s recommendations.

Related Safety Flashes

-

IMCA SF 09/17

3 May 2017

-

-

IMCA SF 03/15

3 March 2015

-

IMCA SF 07/11

19 July 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.