Lost Time Injuries due to a failed mooring line

- Safety Flash

- Published on 4 July 2022

- Generated on 30 June 2025

- IMCA SF 16/22

- 3 minute read

Jump to:

Three crew members were gathered at the stern of the vessel when the port aft mooring line failed. It ‘snapped back’, striking and injuring two of them.

What happened?

A vessel was mobilising and was moored stern to the quayside. It was moored with one aft mooring rope at each side and thruster control from the vessel, to maintain position while the load-out operations were carried out. During a pause in the work, three crew members were gathered at the stern of the vessel discussing the next part of the job, when the port aft mooring line failed. The line ‘snapped back’, striking and injuring two of them. They were taken to hospital.

The incident resulted in two LTIs, in which the injured persons were off work for over three days. One person suffered severe concussion at the scene (was awake but confused) and needed four stitches on the ear and experienced muscle pain in neck. The other person suffered muscle pain in the back and neck and dizziness in the days after the incident.

The incident was considered high potential as it could have resulted in more severe injuries including at least one fatality.

What went wrong?

- The mooring line failed as a combination of several factors described below.

- The stern to berth mooring was not covered by the Risk Assessment for the mobilisation.

What were the causes?

The following causes all contributed to the incident:

- It was believed that the right amount of thrust was being applied to the vessel by the bridge team.

- There was friction on the rope from the rail on the quayside.

- The crew involved thought they were standing in a safe area.

- The length of the port aft mooring line had been shortened to take up the slack.

- It was easier (less work, more convenient) to moor via the dolly rather than the Panama fair lead.

Lessons learned

- Upgrade CCTV cameras used for monitoring the mooring lines with cameras with better resolution, and if possible, with zoom capability, to improve the visual overview presented to the bridge team.

- There should be risk assessments to cover the safest means of stern to quay mooring including:

- suitability of quay facilities and mooring arrangements for future loading of mooring spread.

- identification of snap back areas and ensuring personnel are aware of these areas (line of fire).

- use of protection for mooring lines.

- Use of gangway.

- Decide which mooring line protection materials will be needed and provide a supply of these on the vessels (NB use of protection will be determined by risk assessment).

Our member took the following actions

- Ensure that the stern to berth mooring operation is fully and suitably risk assessed to cover all relevant scenarios.

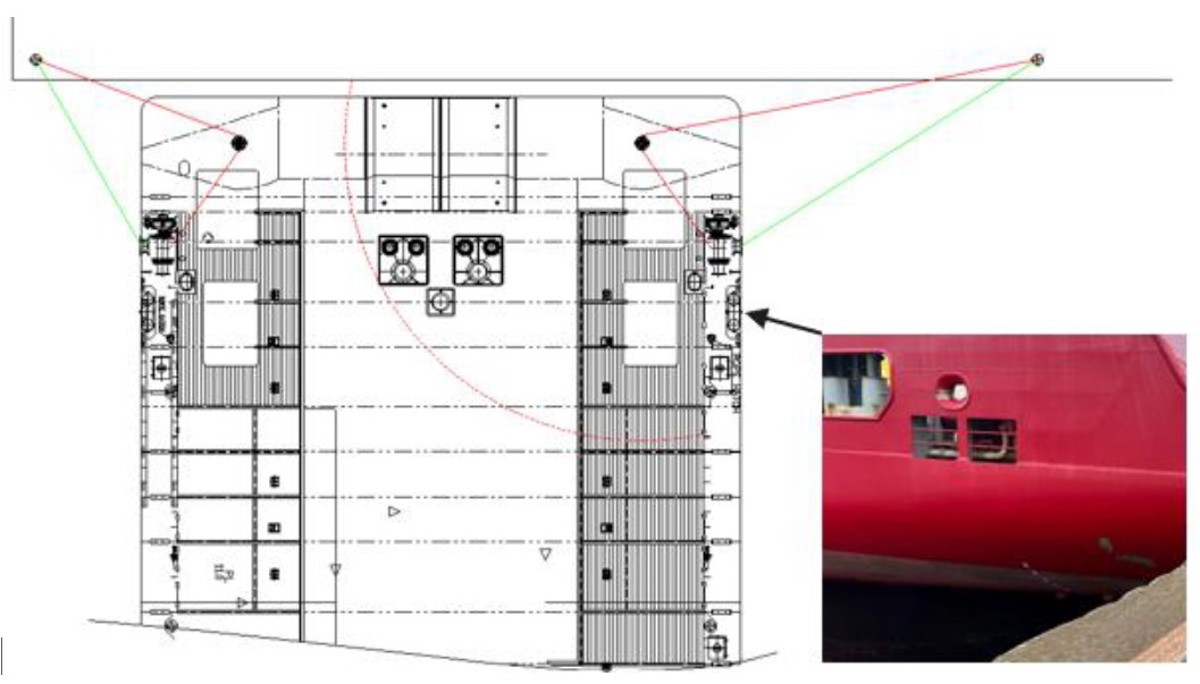

- When arrangement on quayside allows, route the mooring line directly to chock on hull side (green line) instead of over guide roller on the stern (red line) to avoid line of fire/snapback zone on working deck. (see illustration).

Related Safety Flashes

-

IMCA SF 13/21

6 May 2021

-

-

IMCA SF 03/21

19 January 2021

-

-

IMCA SF 11/15

10 August 2015

-

IMCA SF 12/14

14 July 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.