Mini transponder falling from crane wire to deck

- Safety Flash

- Published on 19 December 2008

- Generated on 24 February 2026

- IMCA SF 18/08

- 2 minute read

Jump to:

A Member has reported an incident in which a mini transponder attached to the crane wire came loose and fell 20 m to the deck.

What happened?

A 35m long pennant wire with a guide anchor in the end was being used to open/close hatches on templates. After closing hatches the wire was recovered to deck. A mini transponder was attached to the crane wire just above the crane hook, with two hose clamps. Due to the length of the forerunner the crane had to lift it as high as possible and the wire remaining outside the side of the ship had to be manhandled over the rail. Due to a failing end stop mechanism the crane was hoisted too far and the mini transponder was torn off the crane wire and fell to the deck, narrowly missing two members of the crew who were under the crane ready to manhandle the wire end in on to the deck. There were no injuries.

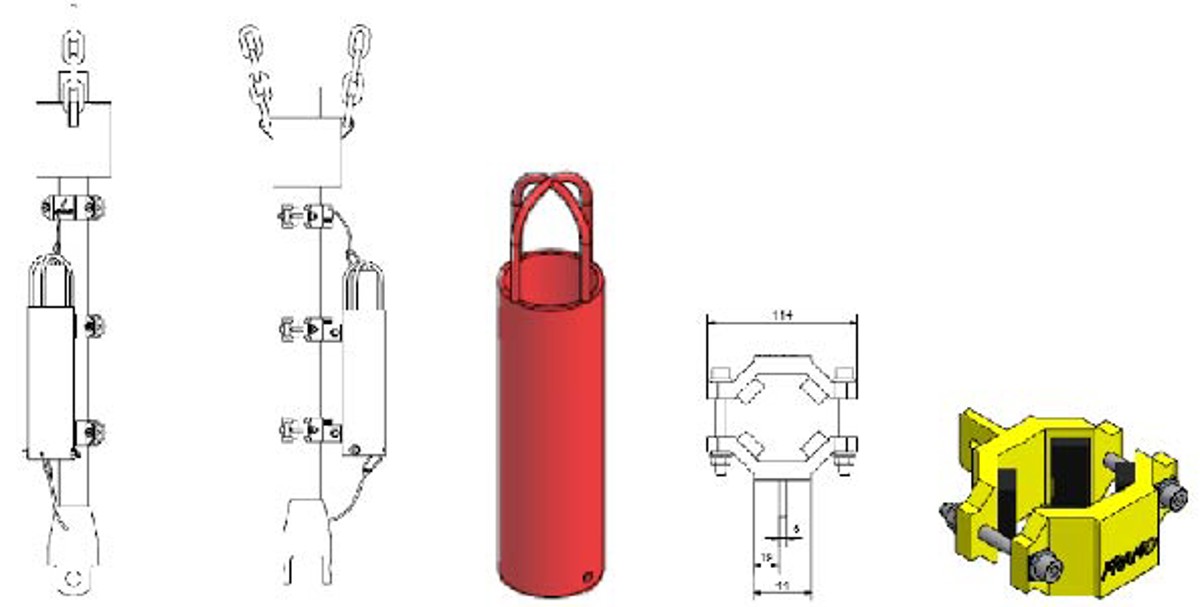

Transponder bracket design

The following points were noted:

- Deck personnel should not have been under the load or in the lifting area.

- Deck personnel should be reminded to always wait for a signal from the crane driver before moving into a lifting area.

- The practice of attaching the transponder to the crane wire should be identified as a risk and discussed appropriately at toolbox meetings beforehand.

- The faulty end stop mechanism on the crane was repaired – as this mechanism was the only barrier preventing the wire from being hoisted too far, the electrical switches on the end stop mechanism were replaced with switches of a better quality.

- A formal procedure was implemented for safely attaching the transponder to the crane wire.

- A purpose-designed transponder bracket was designed and fabricated for fastening these to the crane wire, such that the transponder itself cannot hit the end stop block.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.