Near-miss: ROV shackle (potential dropped object)

- Safety Flash

- Published on 20 December 2013

- Generated on 25 February 2026

- IMCA SF 18/13

- 3 minute read

Jump to:

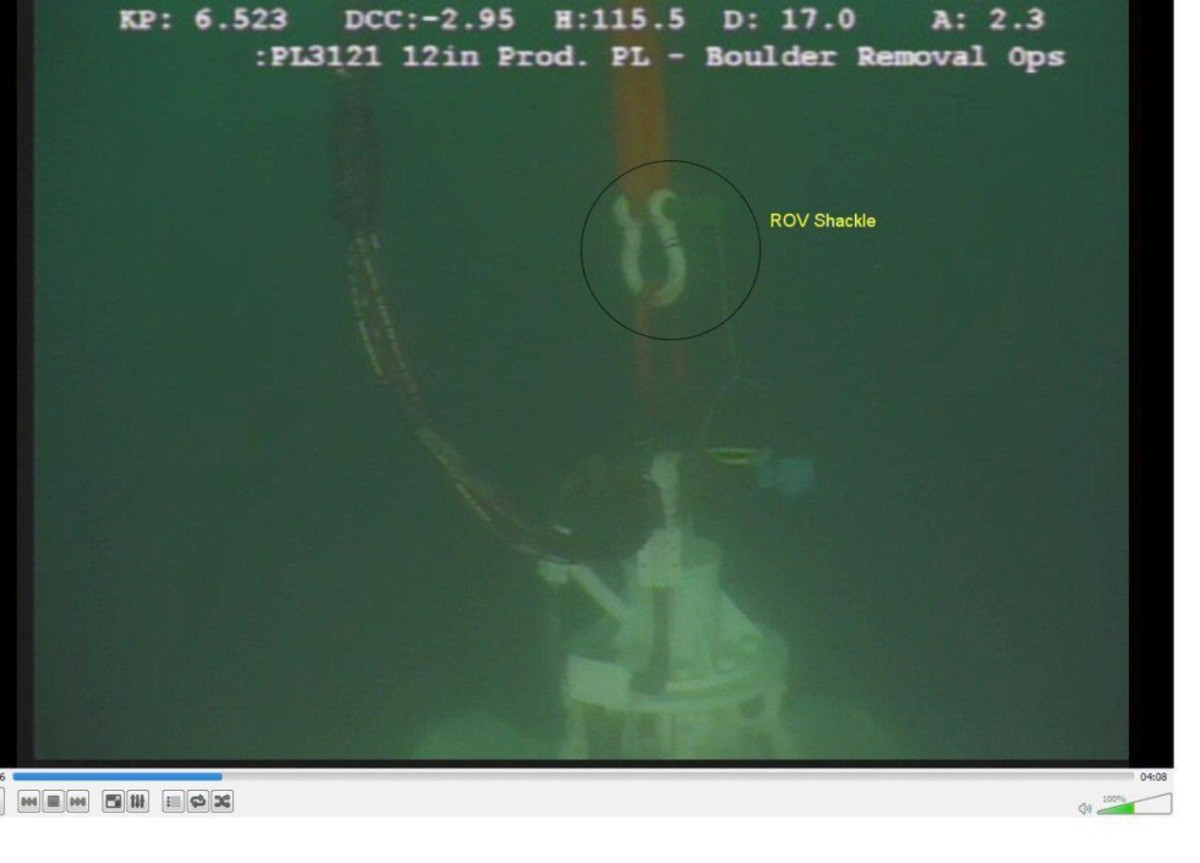

A Member has reported a near miss incident in which an ROV shackle holding a boulder grab became loose and the pin partially disengaged.

What happened?

The incident occurred during a subsea boulder removal, along a pipeline route. A construction vessel had been working continuously for approximately 19 hours, conducting a boulder removal operation. The ROV operator spotted that the ROV shackle on the boulder grab had become loose and the pin was partially disengaged.

The decision was made to lower and land the boulder grab on the seabed. This was done in a safe and controlled manner. Following further toolbox and management of change and risk assessment talks, the boulder grab was recovered and the rigging changed to make it safe.

figure 1: showing shackle (white) and pin (green) partially disengaged

figure 2: shackle, pin and R-clips shown loose

figure 3: shackle, pin and R-clips – complete arrangement

The ROV shackles are designed to allow easy release by the ROV. This incident demonstrates that there is also the potential for snagging risks, particularly during long, repetitive periods of work.

The replacement shackle and rigging arrangement, (25Te ROV shackle for 25Te anchor bow shackle c/w split pin) did not compromise the ability to abandon the boulder grab in any emergency situation.

The preferred option is to remove the requirement for ROV shackles altogether. The 25Te anchor bow shackle should be connected directly to the boulder grab (where possible) and the soft sling rigging arrangement. In an emergency situation, the ROV would cut the soft sling and release the boulder grab.

What were the causes?

Our Member’s investigation revealed the following potential causes of the near miss incident:

- The positioning of the ROV shackle arrangement (just above the boulder grab), there was the potential for the ‘R-Clips’ securing the wire to become snagged, on other rigging or the boulder grab.

- Every time the boulder grab landed on the sea-bed to move a boulder, the rigging would slacken. This repeated action, over 19 hours continuous use, could have resulted in the ‘R-Clips’ becoming dislodged and the pin working loose.

Actions

Our Member took the following actions:

- Lowered the boulder grab to seabed.

- Undertook a toolbox talk, management of change and further risk assessment, prior to recovery to deck of boulder grab.

- Altered the rigging: (25Te ROV shackle – 25Te anchor bow shackle c/w split pin).

- Considered (where possible) removal of the ROV shackles and replacing with 25Te anchor bow shackle (c/w split pin), connected straight to soft sling and boulder grab.

Recommendation

- Members are advised to be aware of the potential snagging risks and to re-assess the use of ROV shackles prior to their use.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.