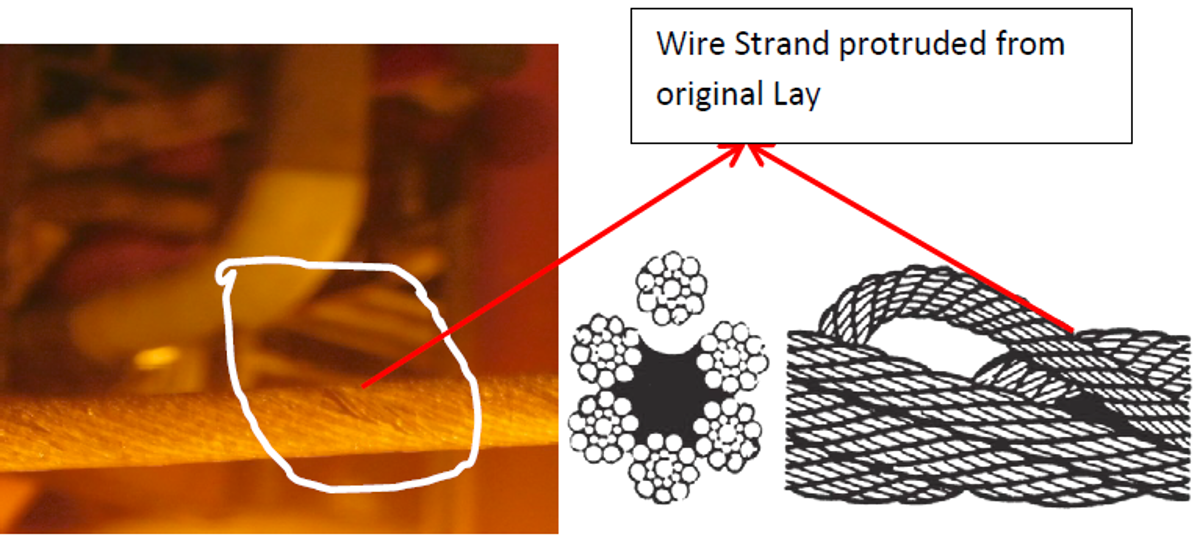

Near miss: Single wire strand protruded from original lay

- Safety Flash

- Published on 25 July 2017

- Generated on 10 February 2026

- IMCA SF 18/17

- 1 minute read

Jump to:

During deployment of the bell and clump weight from a vessel for subsea inspection of a riser line, it was observed that a single wire strand protruded from original lay (‘high stranding’).

What happened?

The bell was recovered, the clump weight wire was visually inspected, and it was determined that 60 m of damaged rope should be cut back. The damaged section was removed and the rope re-terminated.

Third party mandatory load test and certification of the item was carried out and certified as fit for purpose and diving operations resumed.

What lessons were learned?

- The clump weight should not remain subsea during periods of increased tidal current above the limit recommended for diving operations.

- There should be thorough visual inspection of all the ropes and sockets during recovery and deployment of clump weight.

- Ensure frequent monitoring for the ropes and sockets, and any findings recorded.

- Any small defects, damage or abnormality on ropes should be brought to the attention of the Competent Person.

- Precautions should be in place to avoid stress on ropes caused by adverse weather conditions.

Related safety flashes

-

IMCA SF 15/17

15 June 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.