Rigging incident: Damage to bow hand rail on a crew transfer vessel (CTV)

- Safety Flash

- Published on 23 November 2015

- Generated on 18 July 2025

- IMCA SF 19/15

- 2 minute read

Jump to:

A Member has reported an incident in which the bow rail of an offshore renewables crew transfer vessel was damaged.

What happened?

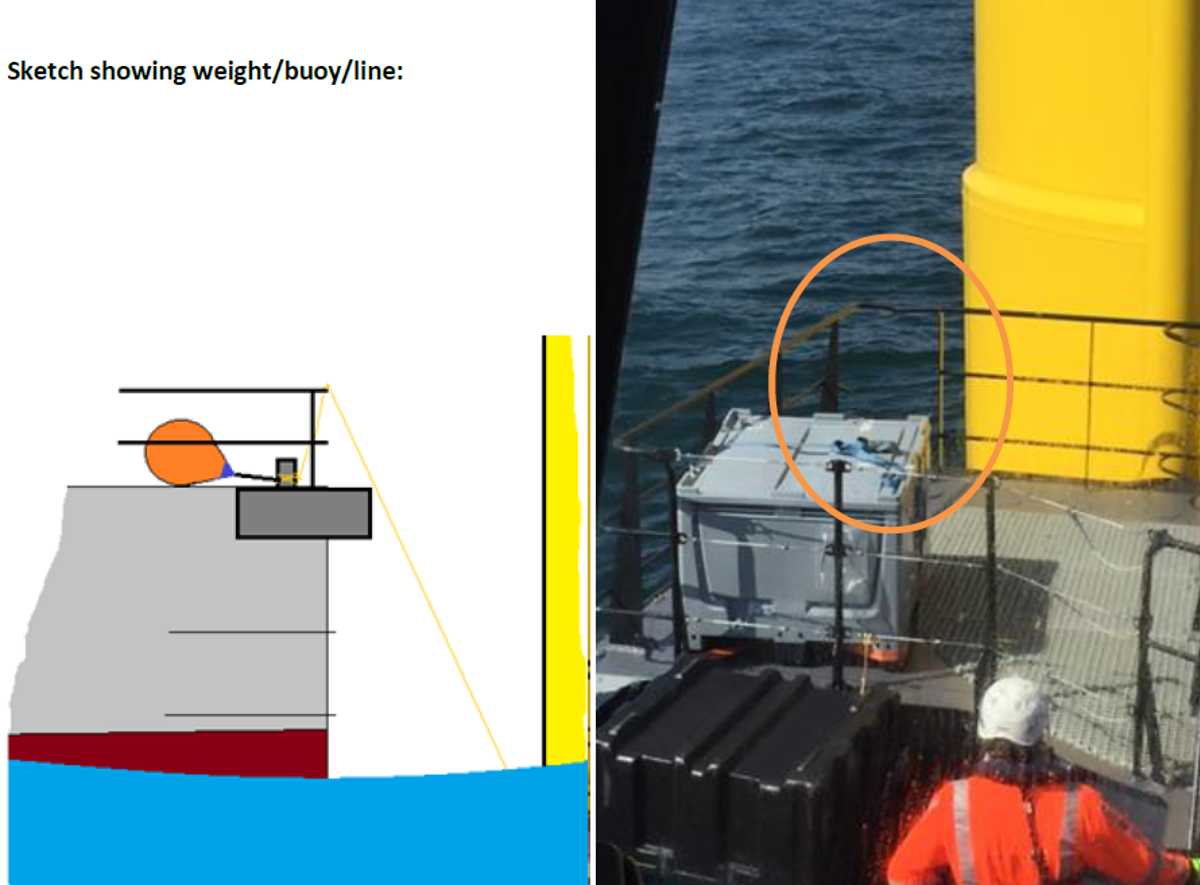

The incident occurred whilst retrieving a buoy and clump weight on the seabed next to a wind turbine generator monopile. The line attached to the weight snagged, damaging the vessel’s bow railing. Crew were on the foredeck retrieving a buoy from the monopile (attached to a clump weight of 15-20 kg which was on the seabed).

Once the buoy had been lifted on-board, two riggers quickly began retrieving the loose line until it became taut against the weight on the seabed. As they began to pull the weight up from the seabed it became snagged. The riggers fixed the line to the forward cleat so that they could reposition themselves to pull harder.

Unknown to the Master, as his vision was very restricted with a large grey storage box on the foredeck, the riggers had pulled the line over the top rail and made fast to the bollard below. The rope drew tight and personnel positioned themselves away from the bow to avoid the snap back zone. The rope did not snap but it cut through the top rail and broke the middle rail off completely.

damaged bow rail on CTV

sketch showing weight, box and line, and photo

Our member noted the following:

- A toolbox talk had been held on-board, including the Master and superintendent before the work took place, and at no point was it discussed that the line would be tied to the forward cleat.

- The incident was discussed on-board after its occurrence and it was highlighted that in the event of snagging, the line should never be tied to the vessel and nothing should ever be tied over the handrails.

- The handrail was repaired on the next maintenance day.

Related safety flashes

-

IMCA SF 07/15

29 May 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.