Catering crew unfamiliar with firefighting systems and emergency stops

- Safety Flash

- Published on 12 July 2021

- Generated on 4 March 2026

- IMCA SF 19/21

- 2 minute read

Jump to:

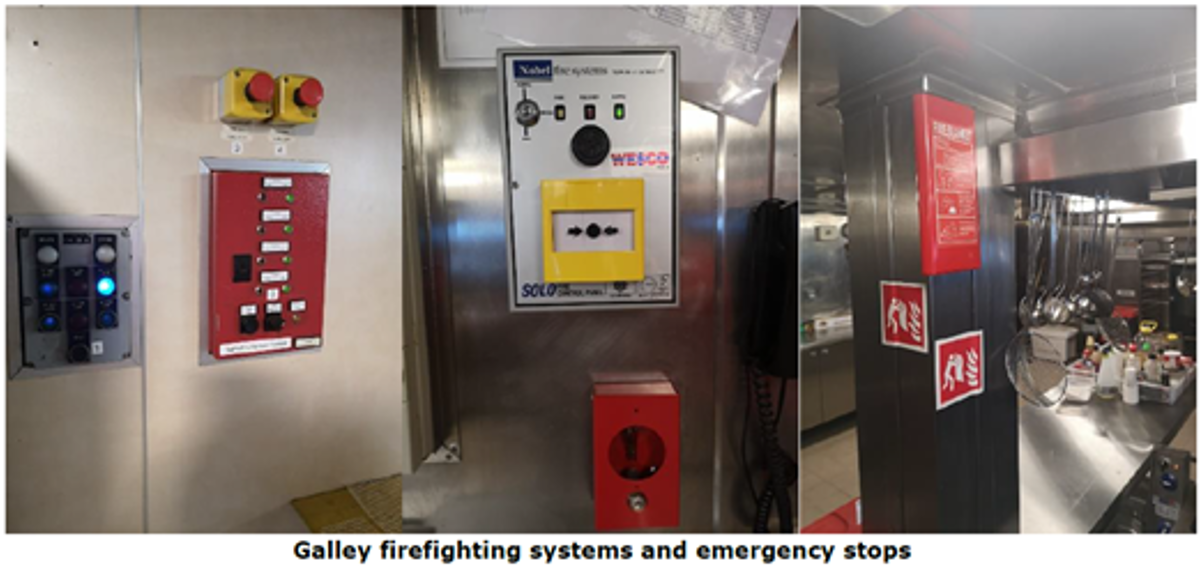

During a recent incident on a Members’ vessel, the catering crew were found to be unfamiliar with the firefighting systems and electrical equipment emergency stops.

The lack of awareness came to light when there was a water leak in the galley during testing of the vessel’s fire pumps. The water leaked into electrical equipment and there was the potential for electrocution of the catering crew.

The engine room crew were called and were able to safely isolate the galley electrical systems using the power supply emergency stops. The catering crew however were unfamiliar with the emergency stops.

A recent audit finding, on another vessel, further highlighted the lack of awareness of the catering crew about the location and use of firefighting systems in the galley.

Actions

- Ensure that all catering personnel complete all mandatory familiarisation on joining the vessel.

- Review levels of awareness with your catering crew and if required, cause catering crew to repeat appropriate familiarisation.

- Chief Stewards should regularly emphasise the location and use of galley firefighting systems and emergency stops in daily Toolbox Talks.

- Maintain galley fire drills, and if necessary, increase the frequency of galley-related fire drills to ensure all catering crew have sufficient awareness and confidence to use galley related firefighting systems and electrical emergency stops for galley equipment.

- Ensure emergency stops in the galley are fitted, operational, visible, easily accessed and marked appropriately.

Related Safety Flashes

-

IMCA SF 08/21

17 March 2021

-

-

IMCA SF 03/20

30 January 2020

-

-

IMCA SF 13/19

4 June 2019

-

-

IMCA SF 07/11

19 July 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.