High potential: dropped chain assembly

- Safety Flash

- Published on 3 August 2023

- Generated on 6 March 2026

- IMCA SF 19/23

- 2 minute read

Jump to:

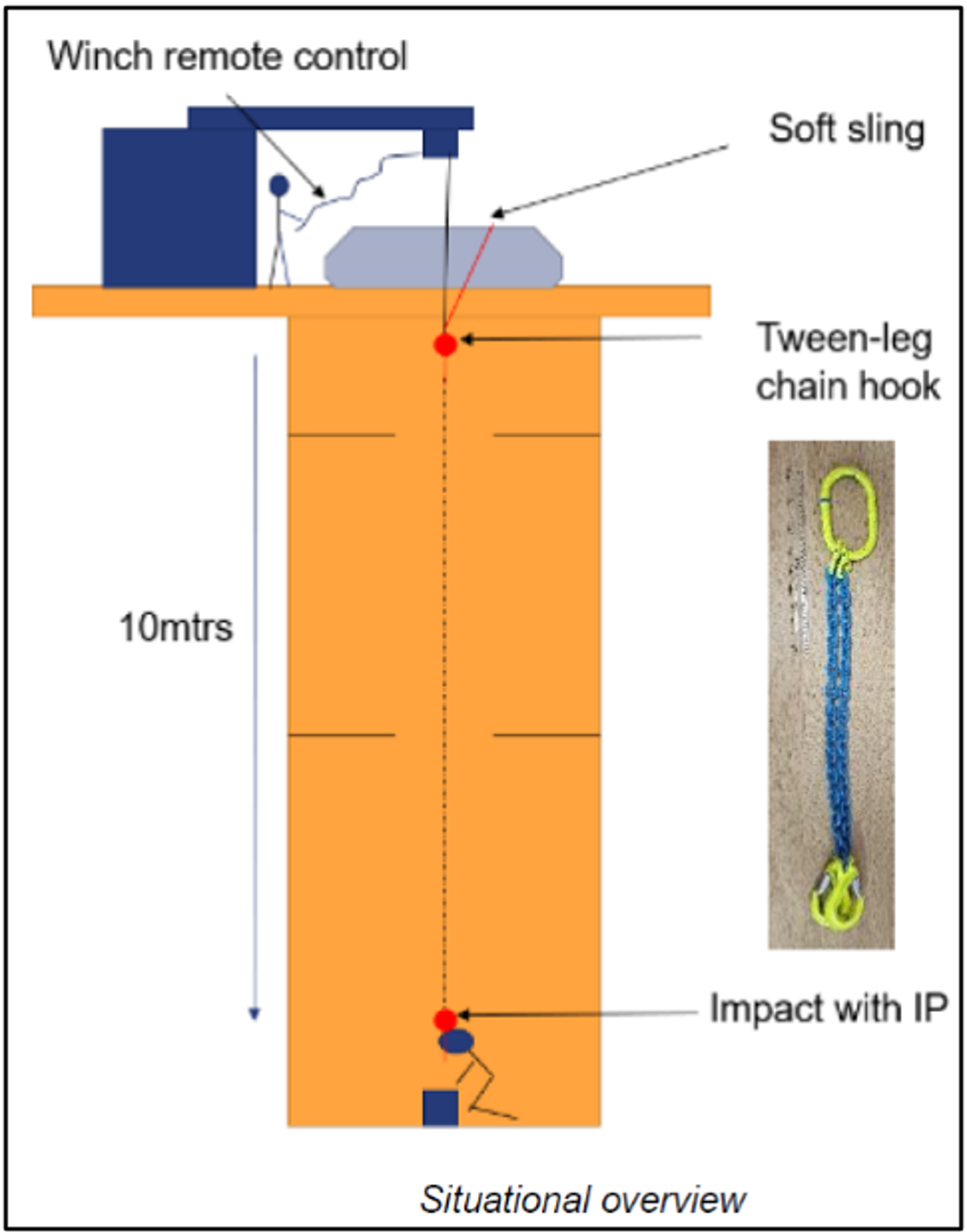

A chain assembly weighing 2.3 kg fell 10 m to deck, glancing the helmet of a person working below, but potentially causing fatal injuries

What happened?

A chain assembly weighing 2.3 kg fell 10 m to deck, just glancing the helmet but potentially causing fatal injuries to a worker below.

The incident occurred during lowering of a two-legged chain and a soft sling. The sling was flapping around due to the wind (9 m/s) and got caught on a railing.

The hook flipped upside down and the master link of the two-legged chain was released from the hook. Consequently the chain fell 10 metres, grazing the helmet of the person working below. The person was shocked but otherwise unharmed.

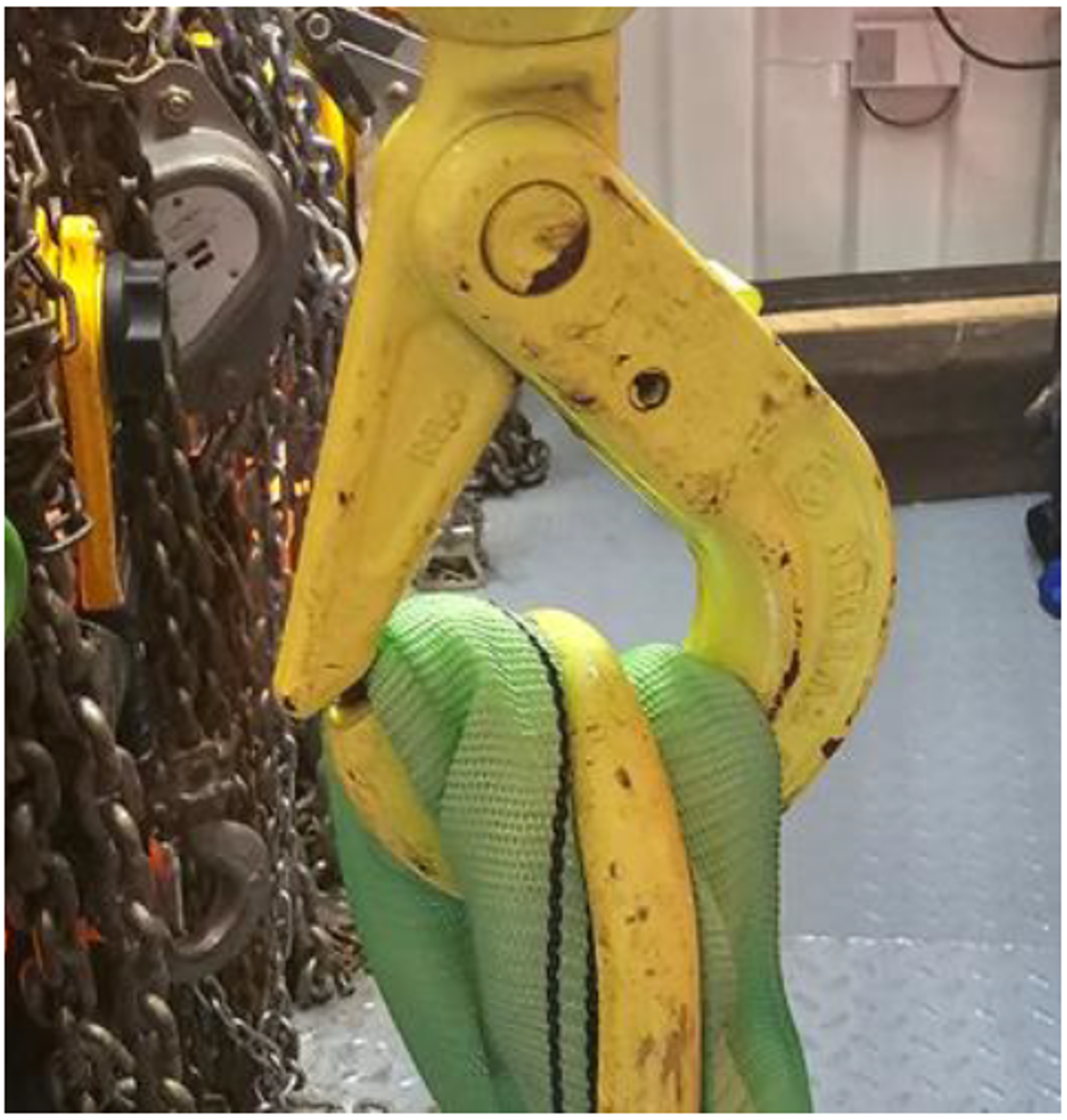

Sling preventing proper closing of the hook

What went wrong?

- The lifting technique was not correct: The fibre of the soft sling was caught in between the hook and latch, preventing the safety mechanism from locking.

- People were in unsafe positions:

- The person with the remote control on the external platform did not have a view of the load he was lowering.

- The injured person was working within the lifting area under the load when the chain and sling was being lowered.

- The person with the remote control on the external platform did not have a view of the load he was lowering.

- Insufficient communication: There was no communication between the two work areas when the chain assembly was being lowered.

Actions

- Always check that the lifting accessories are placed correctly in the hook.

- Ensure there are no people under the load – including the rigging itself which is also to be considered a load.

- Always keep an eye on the lift.

- Communicate lifts and inform team members on restricted areas.

- Does the crew have sufficient experience to perform the given tasks safely?

- Supervise less experienced colleagues.

- Follow the Life Saving Rules; wear PPE.

Members may wish to refer to:

Related Safety Flashes

-

IMCA SF 07/20

26 February 2020

-

-

IMCA SF 07/20

26 February 2020

-

-

IMCA SF 22/19

17 September 2019

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.