Hull crack arising from vibration

- Safety Flash

- Published on 7 November 2025

- Generated on 21 February 2026

- IMCA SF 20/25

- 1 minute read

Jump to:

A small vessel built of aluminium experienced vibration coming from the propeller.

What happened?

It was initially suggested that the vessel had been damaged hitting a floating object, and that following assessment, that the damage was minimal permitting continued operations.

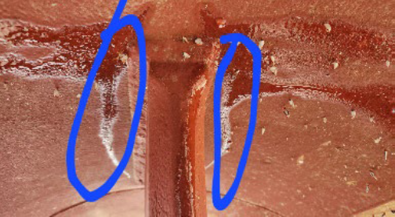

However, a few weeks later a crack in the vessel skeg was discovered as water was leaking into the steering room. Crew installed a cement box to stop the leaking. Shore-based management required the vessel to stop operations for repairs.

What went wrong?

The decision to continue operations and underestimate the vibration on the aluminium vessel led to increased structural stress and led to the hull crack.

Aluminium has a lower fatigue threshold than steel, making it more prone to cracking under repetitive stress or vibration.

Vibration is very critical in aluminium vessels. Vibration was ignored and the vibration caused further cracks that could potentially have caused a serious leak and sank the vessel.

Lessons

Never underestimate vibration – particularly if there is a change or increase in vibration. Have a suspicious mind: investigate, don’t ignore it.

|

|

|

|

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.