Getting fall arrest equipment right

- Safety Flash

- Published on 29 August 2023

- Generated on 10 February 2026

- IMCA SF 21/23

- 2 minute read

Jump to:

Despite a permit to work being in place for a crew member to work at height on a vessel, the length of fall arrest equipment was found to be greater than the height at which the crew member was working

What happened?

A crew person was changing the lamp bulbs on the vessel mast, working at a height of around 4m above the deck. The person was wearing a full set of PPE including a certified safety harness with a lanyard equipped with a shock absorber. There was a Permit to Work in place.

However, the total length of all this safety equipment had not been properly taken into account.

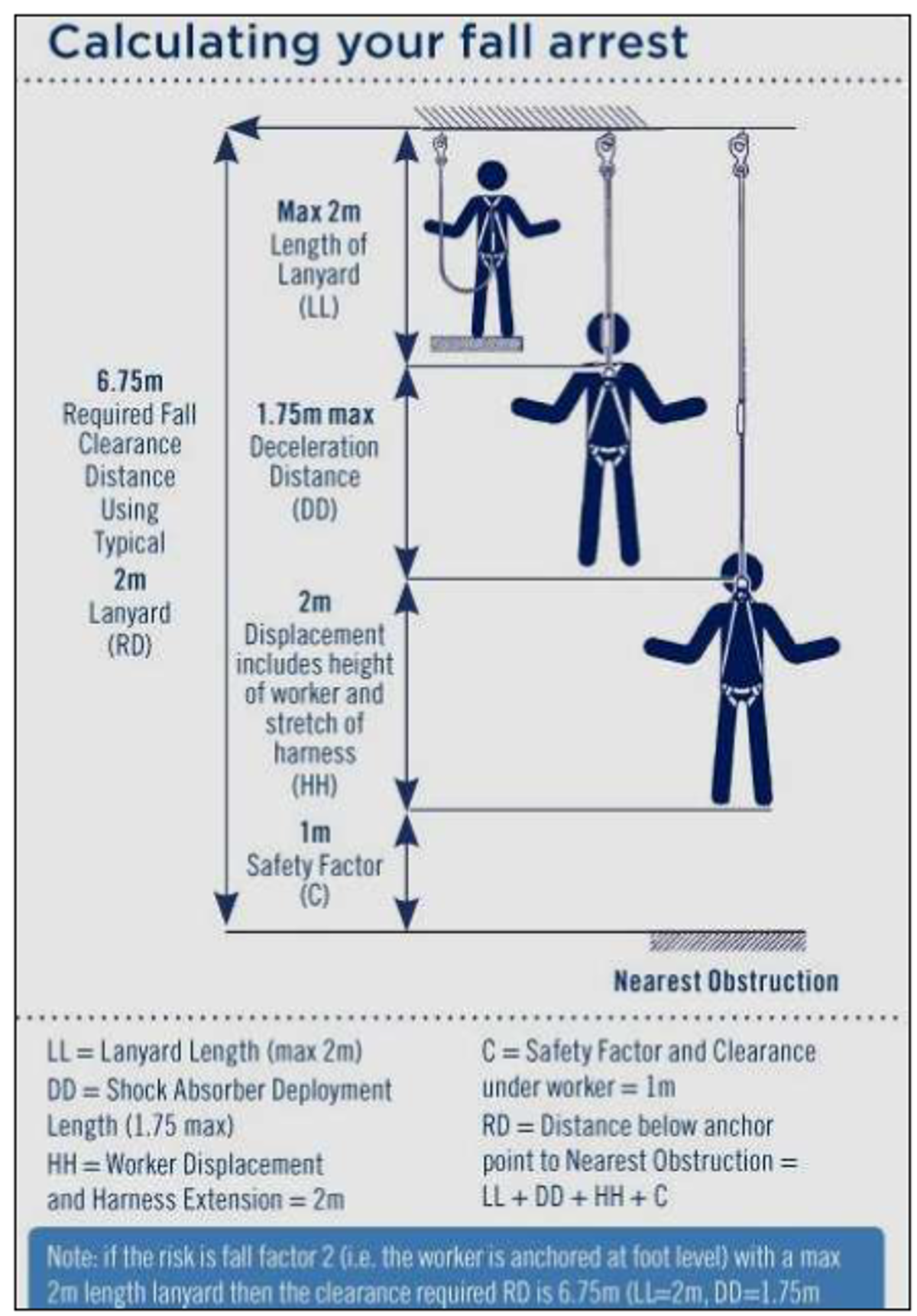

- 1.75 m: the safety lanyard shock absorber

- 2 m: the lanyard itself

- 1.9 m: the approximate height of the person being protected.

This added up to 5.65 m, whereas the person was working 4 m above the deck.

In the case of a fall from height, the fall arrest equipment would have been of no use and the person could have fallen to deck unprotected. He did not fall – no-one was injured.

What went right?

The crew person was wearing fall arrest equipment and there was a Permit to Work in place – some incomplete assessment of risk had at least taken place.

What went wrong?

- The risk assessment was not adequate; no-one thought to check that the proposed work height relative to the length of the fall arrest equipment.

- No-one noticed or considered that the fall arrest safety lanyard was clearly marked “Minimum 6 m clearance distance” (see image).

Actions

Correctly calculate your fall arrest!

Related Safety Flashes

-

IMCA SF 16/20

22 May 2020

-

IMCA SF 02/10

8 April 2010

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.