BSEE: Hazards to Personnel During Lifting Operations

- Safety Flash

- Published on 12 September 2023

- Generated on 21 February 2026

- IMCA SF 22/23

- 4 minute read

Jump to:

The United States Bureau of Safety and Environmental Enforcement (BSEE) has published Safety Alert 468 relating to “red zone” or LINE OF FIRE hazards and increased risk during lifting operations.

What happened?

BSEE defines “red zone” hazards, as hazards that “occur when a worker is in the direct path of an object if a release of energy from that object would cause the worker to be hit, struck, pinched, impaled, crushed, or caught between objects. Injuries from red zone incidents range from minor incidents, such as a pinched finger, to fatalities.”

BSEE notes that the offshore work environment is inherently hazardous with heavy equipment, swinging lines, complex machinery, and a myriad of other hazards posing a potential risk to personnel. Recent examples include:

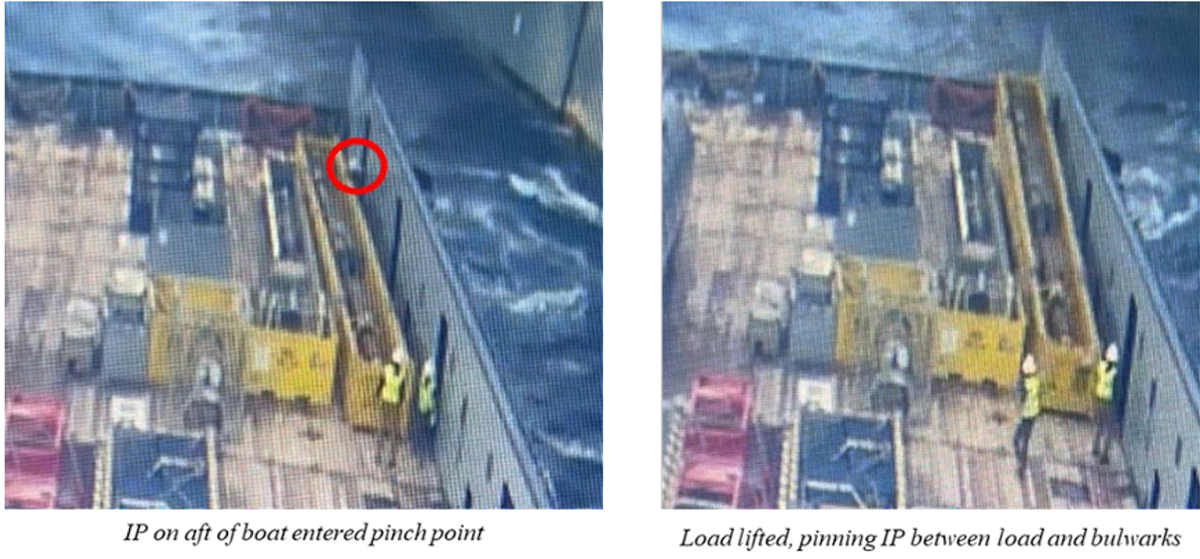

- A rig was in the process of offloading a 20m basket from the deck of an offshore supply vessel when the deck hand was pinned between the load and the vessel rails (see illustration).

- A load shifted during an equipment positioning activity, causing an employee’s arm to be caught between the load and handrail.

- A crane raising a junk tool weighing 3.5 tons shifted toward a worker and pushed him back into a basket that was on the deck.

These are just a few of the dangers workers routinely face when operating offshore. By simply barricading the work areas and restricting access to areas where the worker is exposed to potential harm, an operator can mitigate these risks.

Lessons learnt

BSEE recommends establishing barricades to restrict workers from entering areas where they can be at risk from lifting operations. In addition, BSEE recommends operators and their contractors, where appropriate, consider:

- Developing and enforcing Line of Fire or “red zone” rules and when possible, avoiding all areas barricaded off or designated as higher risk.

- Handling taglines with care. Taglines can become a hazard when tangled or when too close to the load. Making sure taglines are the appropriate length and only used when necessary for the job. Limiting hand placement on the load when possible.

- Using proper rigging (e.g., slings, straps, etc.) and proper lifting devices (e.g. cranes, tuggers, etc.) for each specific job and verifying that they are in adequate condition.

- Being aware of the surroundings and planning an exit route should one be needed. During a lift, watching the load in case it begins to sway and never standing beneath it. Ensuring that you are not in an area where you, or any part of you, can be pinned against something. Making sure there are no obstructions in your vicinity that could be a pinch-point hazard, and always having a clear escape path.

- Constantly monitoring weather conditions. High winds and sea swells will cause increased movement of facilities, vessels, and loads. Stopping the job if the load cannot be fully controlled during heightened weather conditions.

- Avoiding complacency on the job. Offshore is a dynamic environment that must be continuously monitored to ensure safe operations, especially during lifting operations. Maintaining concentration on all tasks throughout a tour, even if monotonous at times. Speaking up at any time if you are experiencing exhaustion and need a break.

- Communicating clearly to ensure everyone is ready to begin the lift and maintaining communication throughout the lift to make sure everything is on track.

Members may wish to refer to:

- IMCA HSS019 – Guidelines for lifting operations

- BSEE Safety Alert 424 – Uptick in Lifting Injuries due to Unrecognized Pinch Point Hazard

- BSEE Safety Alert 445 – Stored energy in slings causes multiple injuries

- BSEE Safety Alert 446 – Unsafe Working Practices Result in Crane Injury

Related safety flashes

-

IMCA SF 23/22

24 October 2022

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.