Hull damage caused oil leakage from settling tank

- Safety Flash

- Published on 14 August 2020

- Generated on 30 June 2025

- IMCA SF 24/20

- 2 minute read

Jump to:

What happened?

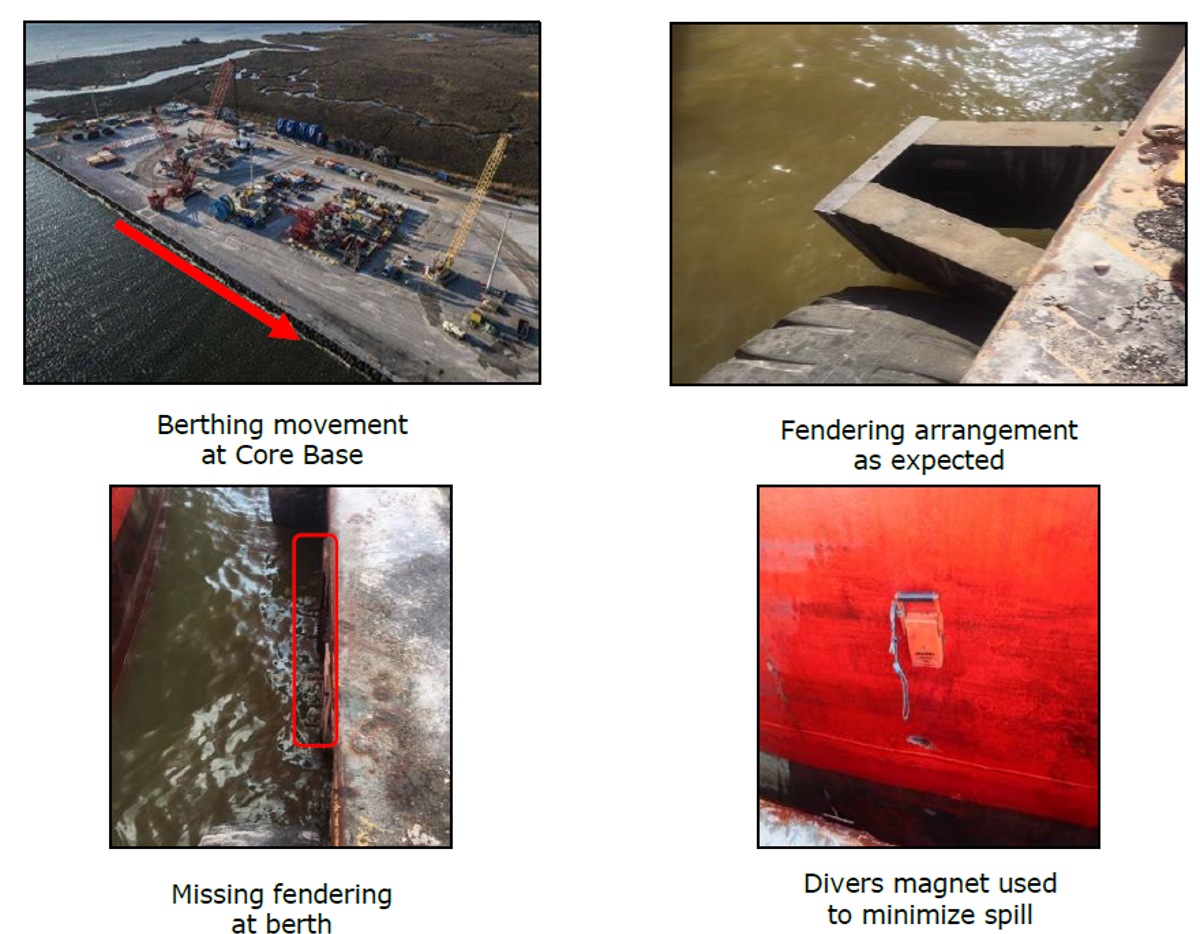

On a member’s vessel, the starboard forward Marine Gas Oil (MGO) settling tank was punctured during berthing operations. The vessel was requested to move berth about 150 metres to accommodate port activities. The manoeuvre was conducted from the bridge wing, providing maximum visibility of the operation. As the vessel mooring ropes were being worked, liquid was observed leaking from 1.5 m above the water line on the starboard side.

As the vessel was berthing a section of missing fendering, just aft of the bow, was contacted and the hull punctured into the starboard forward fuel tank.

What were the causes? What went wrong?

- The maintenance operations underway at the port had not been communicated to the vessel before starting the berthing manoeuvres, and the Master was unaware of the missing section of protective fendering.

- The vessel was operating with restricted personnel access to the quayside due to COVID-19 health controls. Also, the Marine crew did not possess the permissions required by the country legislation for access to secure areas of the base. These constraints prevented any potential observations of missing fenders from the jetty.

- The Task Risk Assessment (TRA) for the mooring task had been reviewed recently by the Master and the Bridge Team with reference to internal procedures and industry good practice. The consideration of damage to the hull/structure had not been considered within this review.

Lessons learned

- Ensure that accurate, appropriate and sufficient information is delivered to the people making the decisions.

- Review task risk assessment for berthing to ensure hazards are fully considered and controlled.

- Whilst crew restrictions restrict quayside access, consider additional shoreside support as available.

- Must outboard tanks be used? Consider where possible alternative inboard arrangements for settling tanks and other tanks with potential pollutants.

- Ensure ongoing review and update of the Shipboard Marine Pollution Emergency Plan following drills and exercises.

Related Safety Flashes

-

IMCA SF 10/16

18 April 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.