Unprotected openings in floor grating – work stopped

- Safety Flash

- Published on 16 October 2023

- Generated on 18 February 2026

- IMCA SF 24/23

- 2 minute read

Jump to:

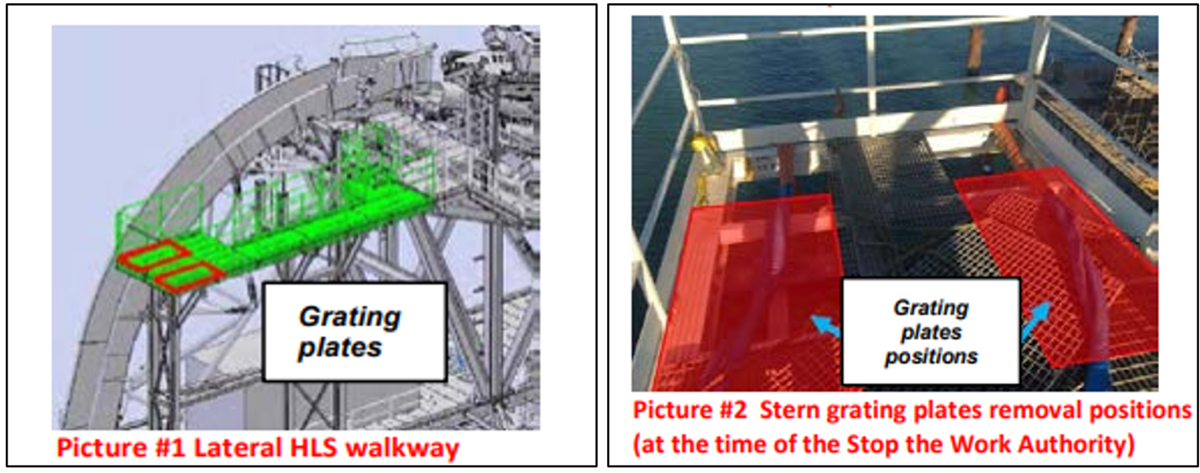

Two workers removed grating panels at height on a horizontal lay system, in order to gain access to lift points for further removal of a lateral walkway section.

What happened?

The removed grating created an open hole with the likelihood that someone could have fallen through it. None of the team involved was wearing the required PPE for working at height and no tool lanyards were used.

The area around the horizontal lay system had not been barricaded. The activity was immediately stopped. No-one was injured; no dropped object resulted.

What went wrong?

No-one involved in the activities perceived that the grating removal created a Work at Height hazard; the risks were underestimated.

What was the cause?

- Inadequate or improper design of controls / barriers – several grating plates had to be removed in order to reach the structural beams needed to access the lift points.

- There was no Permit to Work in place.

- There were unclear or conflicting reporting relationships – information passed to the workers by a “Vessel Field Engineer” was accepted as actual instruction to do the job.

Lessons and actions

- Remember the importance of the Stop Work Authority – this should be used whenever an activity is deemed unsafe.

- Task seen as “routine” – routine activity sometimes leads us to disregarding or underestimating the risks associated with that activity.

- Ensure proper supervision, coordination, and a single point of control for work activities which are carried by two or more different work groups.

- Safety by design: safety aspects should be considered at design phase to ensure any potential hazards are considered, eliminated and/or relevant measures are taken against them.

Our Member took the following actions

- Assessed the feasibility of installing accessible lifting points removing the need to remove grating plates.

- Looked at other project mobile equipment to assess how accessible lifting points are.

- Re-evaluated the need for a Permit to Work when certain activities are carried out in a changed work environment (such as grating removal that could create a WAH hazard).

- Ensured mobilisation / demobilisation plans include designation of single Responsible Person.

Related safety flashes

-

IMCA SF 01/22

10 January 2022

-

IMCA SF 12/20

31 March 2020

-

-

IMCA SF 02/20

10 January 2020

-

-

IMCA SF 20/15

3 December 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.