Fatality: Crew member crushed between TMS and snubber ring

- Safety Flash

- Published on 19 October 2017

- Generated on 21 February 2026

- IMCA SF 25/17

- 1 minute read

Jump to:

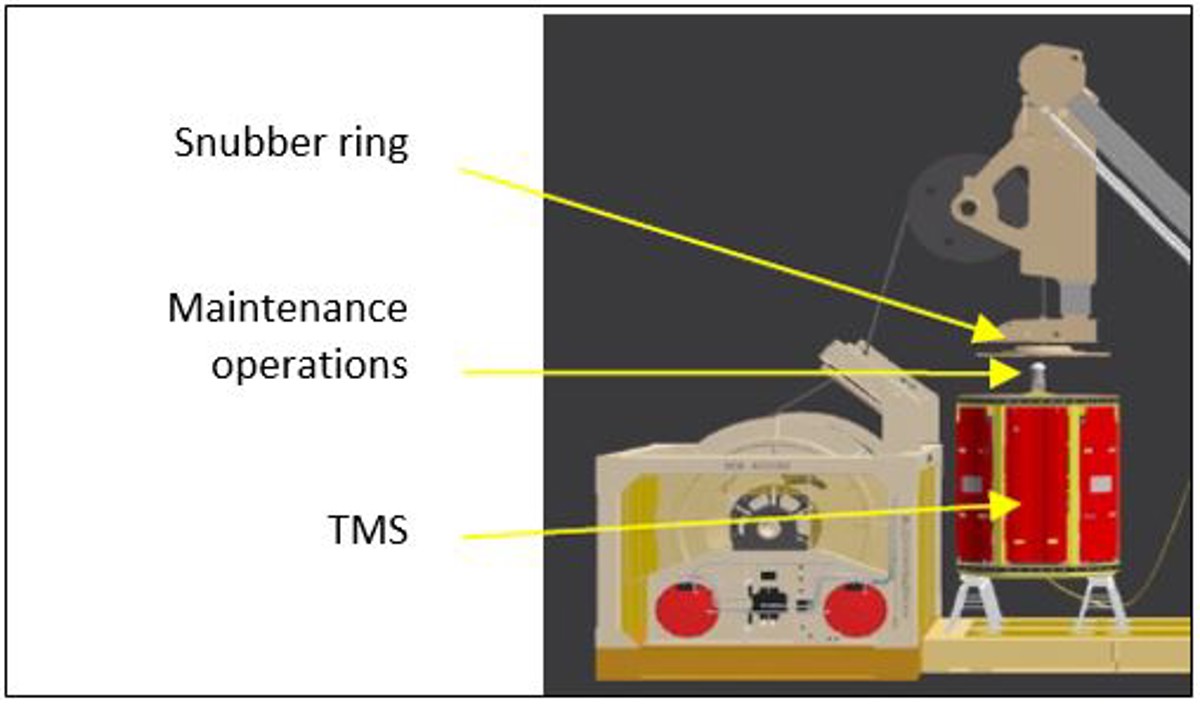

During a maintenance operation, a member of an ROV crew sustained fatal injuries when he was trapped between the top of the tether management system (TMS) and the snubber ring.

What went wrong? What were the causes?

It should be noted that this incident remains under investigation.

Additional information will be provided in due course.

What lessons were learnt? What actions were taken?

- Maintenance activities should be properly risk assessed and undertaken in accordance with company procedures.

- Maintenance activities often introduce additional hazards into the workplace; these should be fully understood, assessed and managed.

- There should be a documented safe system of work, for example, a maintenance manual and/or work instruction.

- If activation of the equipment is necessary to complete the maintenance activity, for example for testing purposes, extreme care needs to be taken which includes removing all personnel from any danger zone.

- Avoid undertaking a maintenance activity under a load or between a load and fixed point.

- Equipment must be turned off and isolated when being worked on.

- The incident highlights the need for strict compliance with the ‘golden’ or ‘life-saving’ rules used by all contractors and clients.

Related safety flashes

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.