Fire-fighting equipment in poor condition

- Safety Flash

- Published on 30 October 2023

- Generated on 4 March 2026

- IMCA SF 25/23

- 2 minute read

Jump to:

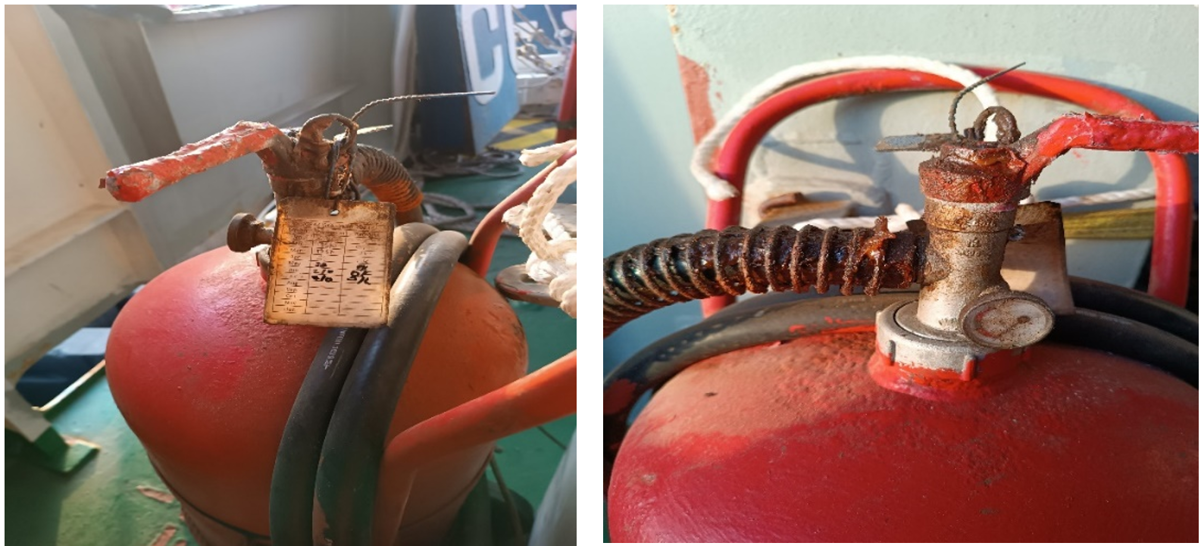

Several 50kg wheeled dry powder fire extinguishers on board a vessel were found to have low pressure and heavy signs of corrosion.

What happened?

The corrosion was discovered during an audit walk-around by shore-based personnel.

Fire extinguishers being absolutely crucial safety equipment on a vessel, they should be maintained to the very highest standards in full readiness for use in an emergency.

Regular thorough inspection of fire-fighting equipment to verify that this is so, is a regulatory requirement in some countries including the UK.

Poor condition of fire extinguishers

What went wrong?

- There had been a regular monthly inspection of the firefighting equipment onboard, but the person inspecting the equipment had not highlighted its poor condition.

- The crew were unaware of the detail and quality required in planned inspection of firefighting equipment.

Actions

- Thorough and comprehensive inspection of all fire extinguishers and fire fighting equipment on board/site to ensure all are in sound workable condition.

- Removal and quarantine of defective fire extinguishers and other safety critical equipment not in safe and usable condition, and relevant repairs or replacements ordered.

- Additional control measures to be put in place until replacements /repairs implemented.

- Regular maintenance: Monthly visual inspection of fire fighting equipment by crew and annual service by authorised third party provider.

- Crew Training: Conduct regular awareness sessions to ensure sufficient knowledge of relevant crew members on how to conduct quality visual inspections of firefighting equipment as well as to emphasise the importance of timely reporting of any safety concerns.

Related safety flashes

-

IMCA SF

9 February 2023

-

IMCA SF 24/21

31 August 2021

-

-

IMCA SF 35/16

20 December 2016

-

IMCA SF 12/16

6 May 2016

-

IMCA SF 03/07

4 April 2007

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.