Near-miss: Open hatches left without barriers

- Safety Flash

- Published on 12 October 2016

- Generated on 5 March 2026

- IMCA SF 27/16

- 2 minute read

Jump to:

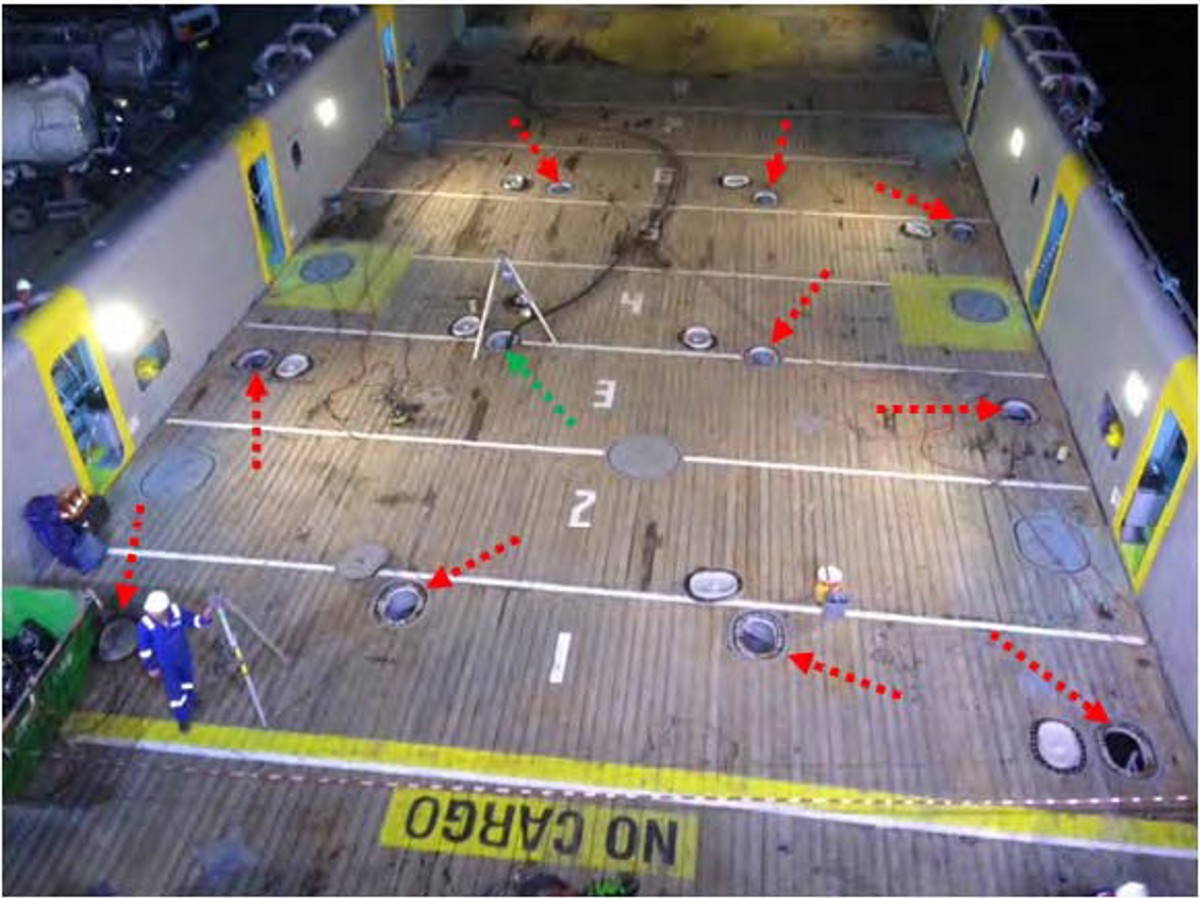

A Member has reported a near miss incident in which a number of hatches on deck were left open without any form of barrier, creating the potential for injury if persons were to fall down the hatches.

What happened?

The incident occurred during ‘routine’ tank cleaning operations carried out by an authorized tank cleaning contractor on board a supply vessel. During night shift vessel inspection and tank cleaning operation monitoring, 10 tank hatches were observed open and left uncontrolled (potential to fall into the manhole for some employees working near the open hatches).

Initial investigation revealed that 11 diesel tank hatches were opened and gas tested; the 10 hatches were left open for ventilation without any protection/control measures or any barriers for each hatch. The overall area was barricaded off by tape by the tank cleaning contractor with a single standby person allocated on deck.

Our member noted the following:

- 10 hatches were left open for ventilation without any barriers.

- There were no additional control measures in place, except a verbal caution during the toolbox talk about the risk of falling into the open hatches.

- The unsafe condition was neither identified nor challenged by any personnel from the contractor or from the vessel crew.

Our member took the following actions:

- Tank cleaning operations were stopped for the moment.

- A safety stand-down was conducted with emphasis on the potential hazards and the requirement to be vigilant and initiate a stop work authority for any unsafe conditions identified.

- Further thorough review of task risk assessment and procedures for tank cleaning and other dangerous space entry activities – with consideration of better management of the open hatches.

- Further clarification of roles and responsibilities during simultaneous operations (SIMOPS) and during tank cleaning.

- Barriers and vented grating ordered for all vessels in fleet.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.