Unsafe lifting operations

- Safety Flash

- Published on 28 September 2020

- Generated on 25 February 2026

- IMCA SF 28/20

- 2 minute read

Jump to:

A Member reports two incidences of unsafe lifting, which are worthy of note.

Incident 1: Unsafe lifting operations by sub-contractor

On a platform supply vessel (PSV) involved in demobilisation operations alongside, the crane operator attempted to lift a winch frame located on at the main deck while there was scaffolding structure still over the winch frame.

In addition, crew were still dismantling the scaffolding and so were in the line of fire.

Upon observing this unsafe condition the job was immediately stopped by the vessel team.

What were the causes? What went wrong?

- Line of fire – there was scaffolding over the lifting area and the presence of personnel in the line of fire was not considered by the contractor.

- Incorrect lifting method – scaffolding pipes were placed under the winch platform with the purpose to roll it over with partial lifting, creating a risk of the winch sliding back off its platform as it was not welded on it.

- People were in a rush – the contractor’s lifting crew were in a hurry to complete the job on that day, as windy weather was forecast for the next day.

Actions taken and lessons learned

- SIMOPS! Take into account what else is happening around you. Avoid any conflicting activities during any lifting operations.

- All lifting operations should be properly planned and risk assessed.

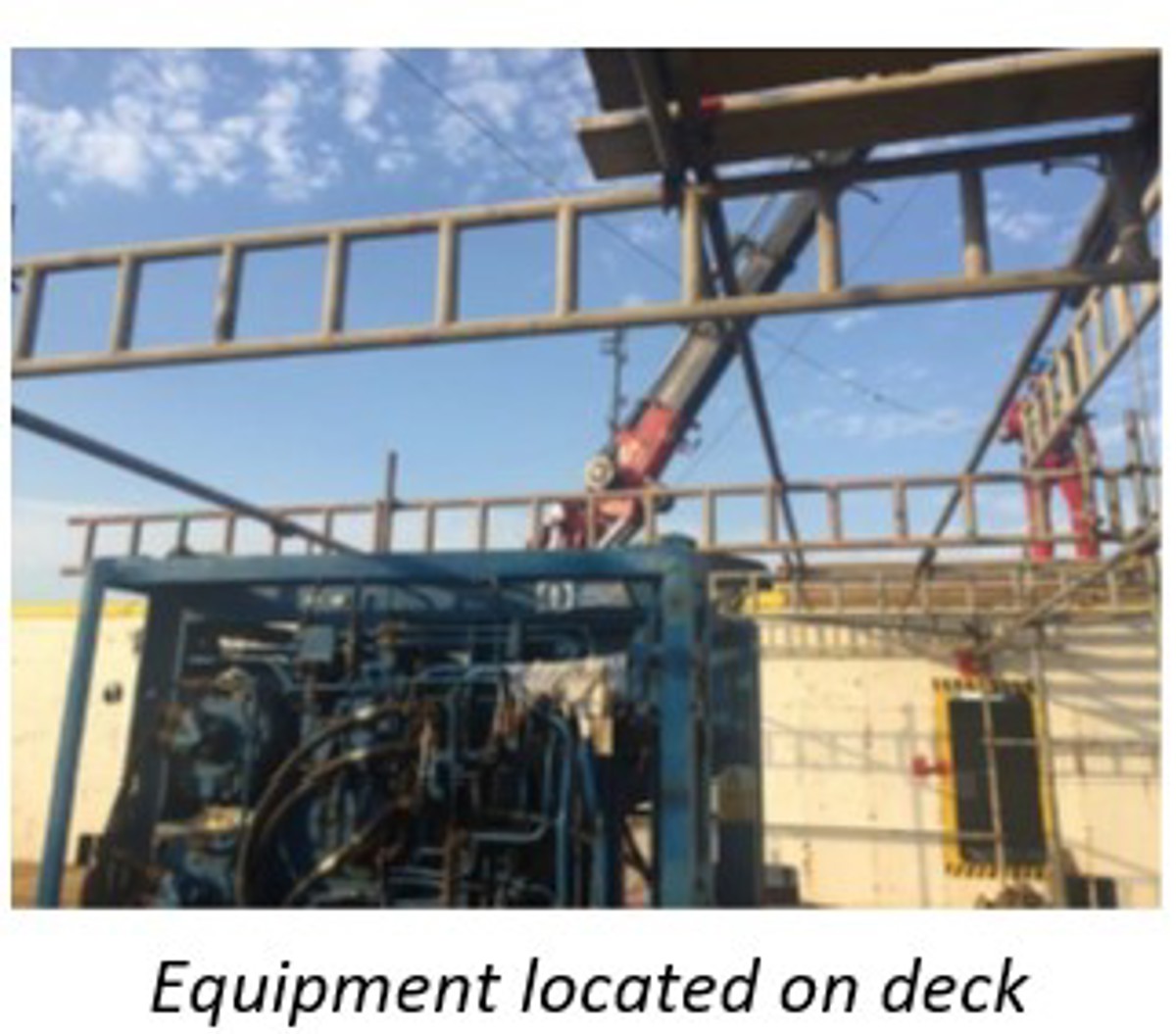

Incident 2: Master stopped unsafe lifting operation

A client’s lifting crew attempted to load a metal structure to the vessel deck.

The operation was stopped by the vessel Master. He questioned the certification of the lifting point and the lifting gear, as having no colour code signs.

As no certificates could be provided, the vessel Master refused cargo and took the matter up with company management and the client’s representatives.

Actions taken and lessons learned

- Crew to conduct vessel inspections to ensure valid colour code applied to all lifting equipment and accessories, as per Safety management system.

- Reiterate the importance of checking lifting equipment condition before and after the task.

Related resources

Members may wish to refer to:

- “Are you prepared to work safely?” videos: Lifting equipment, Lifting operations

- IMCA HSS019 Guidelines for lifting operations

Related Safety Flashes

-

IMCA SF 22/16

1 September 2016

-

IMCA SF 16/09

10 November 2009

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.